Professional Aluminum Polishing for Extrusions

Aluminum polishing improves the surface of aluminum parts by removing scratches, oxidation, and tool marks. This process creates a smooth, reflective finish that enhances both appearance and durability. Polished aluminum resists corrosion and makes cleaning easier, extending the lifespan of products in industries such as automotive, architecture, and electronics.

What Does Aluminum Polishing Involve?

- Surface Cleaning: Technicians remove dirt, grease, and residue using mild cleaners or solvents.

- Sanding: Workers use progressively finer sandpaper to smooth out imperfections and prepare the metal for polishing.

- Buffing and Polishing: Buffing wheels and specialized compounds create a bright, mirror-like surface or a subtle sheen, depending on the application.

Aluminum polishing delivers both visual appeal and practical advantages. This guide explains the process, highlights the benefits, and addresses common questions to help you determine if aluminum polishing meets your needs.

Why Choose Hugh Aluminum for Aluminum Polishing?

ISO 9001-Certified Quality Control

We inspect every aluminum profile using strict protocols. Our team checks for zero surface defects, such as pitting, streaks, or orange peel. We measure surface roughness with Mitutoyo profilometers and confirm Ra values at or below 0.1µm. Every order meets ASTM, GB, and EN standards, ensuring your parts comply with international requirements.

Fast and Reliable Delivery

Our standard lead time is 14–21 days, which is 50% faster than the industry average. We achieve a 99.3% on-time delivery rate, verified by third-party logistics audits. You receive your polished aluminum parts on schedule, reducing project delays and costs.

Precision You Can Trust

We deliver tight tolerances, with ±0.05mm for critical dimensions—twice as precise as the typical ±0.1mm. Laser systems verify straightness within 0.1mm per meter. Our stress-relief annealing process prevents warping, so your parts retain their shape after polishing.

What Sets Us Apart?

- Consistent Results: Every batch meets strict quality targets.

- Clear Communication: We provide regular updates on your order status.

- Industry Expertise: Our team has years of experience in aluminum polishing and finishing.

Contact us for sample inspection reports or to discuss your requirements. Our experts will help you achieve the finish and performance your project needs.

Hugh Aluminum Full Polishing Processes

Hugh Aluminum uses two main polishing methods: mechanical polishing and electrochemical polishing. Each method creates a durable, attractive finish for aluminum extrusions and components.

Mechanical Polishing: Six-Step Process

Mechanical polishing uses abrasives and finishing tools to smooth and brighten aluminum surfaces. The process includes:

1. Deburring

- Carbide rotary files and ceramic media remove sharp edges over 0.1mm.

- This step produces safer and cleaner parts.

2. Coarse Grinding

- Aluminum oxide belts (#60–#120) run at 25–35 meters per second.

- The process removes 0.05–0.15mm of material from each side.

3. Intermediate Polishing

- Scotch-Brite™ wheels (#240–#400) and 5% water-soluble coolant reduce heat and friction.

- This step prepares the surface for fine finishing.

4. Fine Polishing

- Diamond-impregnated nylon brushes (#800–#1500) achieve a surface roughness of Ra 0.2–0.4μm.

- The aluminum feels smooth and is ready for a high-gloss or satin finish.

5. Mirror Finishing (Optional)

- Diamond paste (0.5–3μm particle size) creates a mirror-like surface.

- This finish is ideal for decorative or high-visibility parts.

6. Cleaning & Inspection

- An ultrasonic bath with pH 9.5 alkaline solution at 60°C removes residues.

- White light interferometry checks surface quality.

Electrochemical Polishing: Five-Step Process

Electrochemical polishing uses chemical baths and electrical current to enhance surface smoothness and corrosion resistance.

1. Alkaline Degreasing

- Soak parts in 50g/L sodium hydroxide at 60°C for 3 minutes.

- This removes oils and contaminants.

2. Acid Pickling

- Immerse in a 3:1 mix of nitric acid and hydrofluoric acid at 25°C for 30 seconds.

- This step etches the surface and removes oxides.

3. Electropolishing

- Use a bath of 70% phosphoric acid, 20% sulfuric acid, and 10% glycerol.

- Apply 15V DC, 50A/dm², at 75°C for 5–8 minutes to smooth the surface.

4. Neutralization

- Dip in 5% sodium carbonate for 2 minutes to stop the acid reaction.

5. Passivation

- Apply a chromium-free, RoHS-compliant passivator to increase corrosion resistance.

Choosing the Right Polishing Method

- Mechanical polishing removes defects and creates a range of finishes, from satin to mirror.

- Electrochemical polishing produces a bright, uniform surface with improved corrosion resistance.

- Both methods deliver consistent results for demanding applications in automotive, architecture, and electronics.

The Specification Table of Hugh Polishing:

| Process | Surface Roughness (Ra) | Material Loss | Best for Alloy | Cycle Time |

|---|---|---|---|---|

| Mechanical Polishing | 0.05 – 0.4 μm | 0.02 – 0.1 mm | 6xxx / 7xxx series | 5-15 min/m |

| Electrochemical | 0.02 – 0.1 μm | 0.01 – 0.05 mm | 5xxx / 6xxx series | 3-8 min/m |

| Chemical Polishing | 0.1 – 0.3 μm | 0.03 – 0.08 mm | Cast aluminum | 2-5 min/m |

Types of Aluminum Polishing Services Offered

Polishing for Extruded Profiles and Custom Shapes

We polish standard and complex aluminum profiles for architectural, automotive, and industrial parts. Our team uses specialized tools to reach all surfaces, including sharp angles and curves. This process delivers a consistent finish across every part.

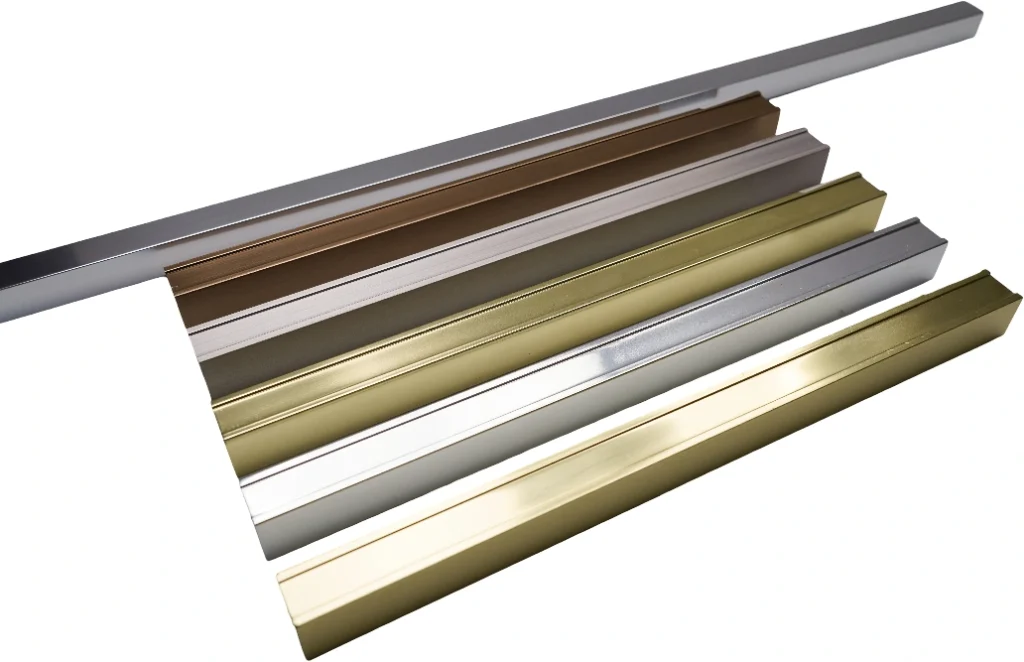

Mirror Finish and Brushed Finish Options

Choose a mirror finish for a high-gloss, reflective surface on decorative panels, display fixtures, or automotive accents. Select a brushed finish for a matte, textured look that hides fingerprints and minor scratches on door handles or public furniture. We provide samples and help you compare finishes for your application.

Flexible Batch Sizes

We process orders from single prototypes to large production runs. Our facility supports short-run custom parts for architecture and high-volume batches for electronics manufacturing. Every batch receives the same attention to quality and detail.

Specialized Applications

Our services cover a wide range of industries:

- Architecture: window frames, curtain walls, decorative facades

- Automotive: trim, wheels, interior accents

- Electronics: casings, heat sinks

- Signage: storefront letters, display panels

- Furniture: table legs, light fixtures

We adjust our process to meet each sector’s requirements for finish, durability, and appearance.

Custom Solutions for Complex Projects

We develop custom polishing processes for non-standard shapes, oversized components, and industry-specific needs. Examples include multi-stage finishes for marine hardware and precision-polished medical equipment. Contact us to discuss your project and see how we can help you achieve your goals.

Applications of Polished Aluminum

Polished aluminum serves critical roles in many industries. Its durable, corrosion-resistant surface and clean appearance make it a preferred material for both functional and decorative uses.

Automotive

- Polished trim, wheels, and grilles provide a bright, reflective finish that resists weather and road salt.

- Interior accents maintain their shine and are easy to clean, reducing maintenance time.

- Polished wheels shed brake dust, keeping vehicles looking new with less effort.

Architecture and Construction

- Cladding, window frames, and handrails use polished aluminum for a modern, reflective appearance.

- These surfaces withstand outdoor exposure and require minimal upkeep.

- Decorative panels and entranceways use polished finishes to create visual impact in public spaces.

Electronics

- Smartphone and laptop casings use polished aluminum for a premium, scratch-resistant finish.

- Audio equipment and consumer devices feature polished trim to signal quality and durability.

Signage and Displays

- Storefront letters and display panels use polished aluminum to attract attention and highlight branding.

- Retailers select this material for its lightweight, weather-resistant properties and easy maintenance.

Furniture and Décor

- Table legs, chairs, and lighting fixtures use polished aluminum to create a modern, open feel.

- Sculptures and decorative pieces benefit from the reflective surface, which enhances room brightness.

Marine and Medical

- Boat fittings and marine hardware use polished aluminum for corrosion resistance in harsh environments.

- Hospitals and laboratories install polished aluminum surfaces for easy cleaning and strict hygiene control.

Lighting

- Lighting manufacturers use polished aluminum for reflectors and housings to improve light output.

- The high reflectivity increases fixture efficiency in both commercial and residential settings.

Polished aluminum combines visual appeal, durability, and easy maintenance. Its broad range of applications demonstrates its value in both everyday products and specialized environments.

Aluminum Extrusion Die Polishing (Special Focus)

Importance of Die Polishing

Die polishing directly affects the quality of aluminum extrusions. A polished die produces smooth, defect-free profiles. This process reduces friction, improves metal flow, and prevents surface marks on finished parts.

Poor die surfaces increase drag and trap debris. These problems can slow production and raise scrap rates. Consistent die polishing keeps output high and defects low.

Die Polishing Process

- Surface Refinement: Technicians use abrasive stones, diamond paste, or felt bobs to remove tool marks and rough spots. This step creates a uniform die surface for clean extrusions.

- Maintenance: Regular polishing removes oxides and wear. A die polished after every 10,000 meters of extrusion can last up to 30% longer than a neglected die.

- Inspection: After polishing, staff check the die with magnifiers or surface roughness testers. They confirm the surface is free of scratches and ready for production.

Best Practices

- Use abrasives that match the die steel and required finish. Diamond paste works for mirror finishes; ceramic stones handle general smoothing.

- Keep the die and extrusion temperatures stable. Overheating causes warping and defects. Cool dies may not polish effectively.

- Apply surface treatments like nitriding or PVD coating to harden the die and reduce future wear.

- Schedule polishing based on production volume, alloy type, and finish requirements. Preventive care avoids downtime and maintains quality.

Example

A window frame manufacturer polishes dies before each run. This routine prevents micro-scratches on the die, so every extrusion has a clean, consistent surface. The result is fewer rejects and better-looking products.

Proper die polishing supports high-quality aluminum extrusion. It improves surface finish, reduces waste, and keeps production efficient. Contact our team for advice on die maintenance or to review sample inspection data.

Benefits of Professional Aluminum Polishing

Enhanced Appearance

Polished aluminum creates a bright, modern finish that improves the look of products and structures. A mirror or brushed finish signals quality and attention to detail in display fixtures, architectural accents, and automotive trim.

Improved Corrosion Resistance

A polished surface protects aluminum from oxidation and rust. Smoothing out pits and scratches helps the metal resist moisture and environmental damage. This protection extends the life of parts used outdoors or in harsh conditions, such as marine hardware and exterior building elements.

Easier Maintenance

Smooth, reflective aluminum surfaces are easy to clean. Dust, fingerprints, and grime wipe away with a damp cloth. Polished kitchen equipment and medical fixtures save time on cleaning and help maintain hygiene standards.

Increased Product Value

A polished finish adds value to products and projects. Customers associate a high-gloss or uniform brushed look with premium quality. Real estate developers and manufacturers often select polished aluminum to boost appeal and resale value.

Customizable Finishes

Professional polishing lets you choose the shine and texture you need. Select a mirror finish for maximum reflectivity or a brushed finish for a matte effect. This flexibility supports a range of design goals and practical requirements.

Versatility Across Industries

Polished aluminum works in architecture, automotive, electronics, marine, and medical fields. Its durability, easy maintenance, and visual appeal make it a reliable choice for both functional and decorative uses.

Professional aluminum polishing provides a durable, attractive surface that protects, simplifies cleaning, and increases value. Contact our team to find the right finish for your application.

Frequently Asked Questions (FAQ)

Can you polish anodized aluminum?

Yes, but use non-abrasive products to avoid damaging the coating.

How do you achieve a mirror finish on aluminum?

To achieve a mirror finish, sand the aluminum with progressively finer grits until the surface feels smooth. Apply a high-quality aluminum polish and use a rotary buffer for an even shine. Remove all scratches from each sanding step before moving to the next grit.

What industries benefit most from aluminum polishing?

Industries that benefit include:

- Automotive: trim, wheels, and grilles stay bright and resist corrosion.

- Architecture: window frames, cladding, and handrails maintain a modern look.

- Electronics: casings and heat sinks look clean and resist fingerprints.

- Signage: storefront letters and display panels attract attention and last outdoors.

How long does aluminum polishing last?

With proper care, polished finishes can last for years.

What is the difference between hand and machine polishing?

Machines provide faster, more uniform results; hand polishing is suitable for small or intricate parts.

How do you maintain polished aluminum surfaces?

Clean polished aluminum with a soft, damp cloth and mild detergent. Avoid harsh chemicals or abrasive pads that scratch the finish. Use a protective wax or sealant to guard against fingerprints, water spots, and oxidation.

Aluminum Polishing Tips and Maintenance Guide

Regular Cleaning

- Wipe aluminum surfaces with a soft microfiber cloth and mild soap solution.

- Avoid abrasive pads or sponges. These materials scratch the finish.

- Rinse with clean water and dry with a lint-free towel to prevent water spots.

Using Polish Products

- Select a polish made for aluminum. Apply in circular motions to restore shine and remove light oxidation.

- Buff with a clean, dry cloth for a bright finish.

- For tough spots, repeat the process on small sections.

Applying Protective Coatings

- Use clear automotive wax or aluminum sealant every few months. This layer blocks moisture and slows oxidation.

- In coastal or industrial areas, wax more often to protect against harsh conditions.

- Follow the product instructions for the best results.

Preventing Damage

- Keep aluminum away from harsh chemicals like bleach, ammonia, or acids. These substances can stain or corrode the surface.

- Use mats under cookware and coasters under drinks to prevent dents and scratches.

- Store aluminum parts in dry, covered spaces to limit exposure to humidity.

DIY Upkeep and Repairs

- For minor scratches, use fine-grit sandpaper (1500–2000 grit) followed by aluminum polish. Sand lightly with the grain.

- For deep scratches or large areas, contact a professional for repair.

- Keep a small kit with polish, soft cloths, and fine sandpaper for quick touch-ups.

Regular cleaning and basic care keep polished aluminum looking bright and new. Use the right products, avoid damage, and address small issues quickly. For help with stubborn problems or large repairs, ask our team for expert advice.

Request a Quote / Contact Hugh Aluminum

Ready to polish your aluminum parts? Request a custom quote from Hugh Aluminum. Our team responds quickly with clear pricing and expert recommendations.

How to Get Your Quote

Provide these details for the fastest service:

- Dimensions: List the length, width, and height of each part.

- Finish Type: Specify mirror, brushed, or another finish.

- Order Volume: Indicate the number of pieces or total batch size.

- Application: Describe how you will use the polished aluminum (e.g., automotive trim, architectural panels, electronics casings).