What is 6005 Aluminum Extrusions Alloy?

6005 aluminum is an alloy made from aluminum and magnesium. Manufacturers use it to create strong, lightweight shapes for many industries. This alloy is popular in construction, electronics, and aerospace.

6005 aluminum resists corrosion. It welds easily. Workers can bend and cut it without much effort. These features make it a practical choice for many projects.

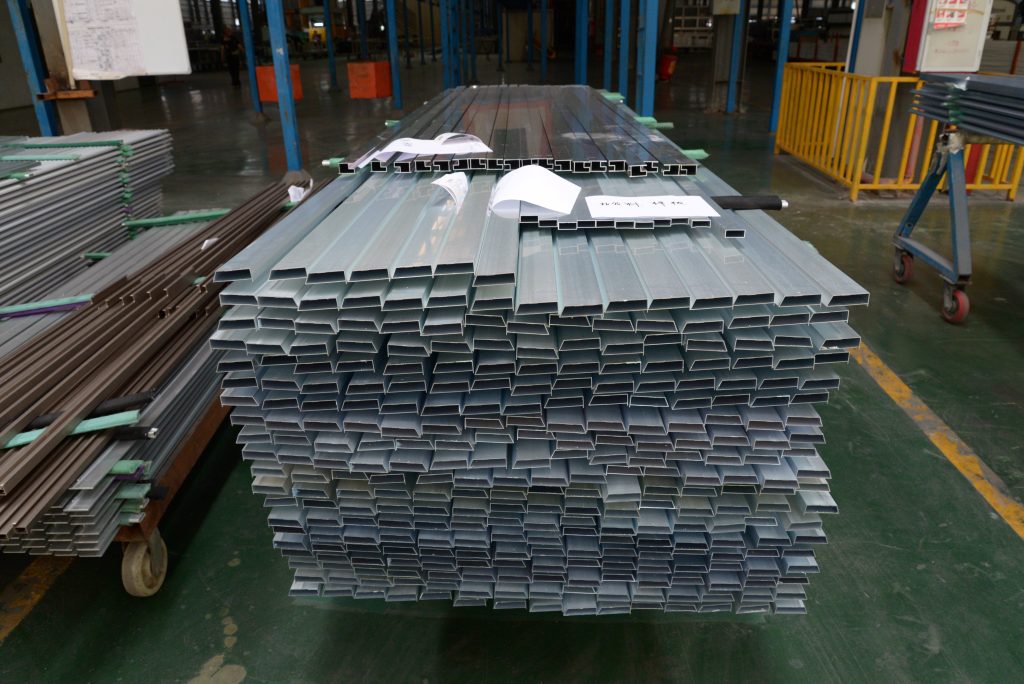

Most often, 6005 aluminum appears as extrusions. Factories push heated metal through a mold to form beams, rails, or profiles. These parts go into buildings, electronic cases, and aircraft.

6005 aluminum is reliable, easy to work with, and fits many uses. If you need a material that lasts and shapes well, this alloy is a smart pick.

6005 Aluminum Alloy Applications

6005 aluminum alloy has many uses across different industries. Its strength and resistance to corrosion make it a reliable material for various parts and products.

Mechanical Parts

Manufacturers use 6005 aluminum to make brackets, supports, and containers. These parts must handle heavy loads and tough conditions. The alloy keeps its shape and resists rust, which helps these parts last longer.

Automotive Bodies and Frames

Car makers choose 6005 aluminum for body panels and frames. The alloy is strong but light. Using it helps reduce vehicle weight. Lighter cars use less fuel and handle better on the road.

Engine Components

Engine mounts and similar parts often use 6005 aluminum. This alloy stands up to high heat and pressure. It does not break down easily, even in demanding engine environments.

Electronic Enclosures and Heat Sinks

6005 aluminum is common in electronics. Manufacturers use it for device cases and heat sinks. The alloy moves heat away from sensitive parts, helping devices stay cool and work well.

6005 aluminum alloy is practical, strong, and easy to use. It supports many products and keeps them working under stress.

Polishing Capabilities and Common Uses

6005 aluminum alloy can be polished to a bright, smooth finish. This makes it useful for parts that need to look clean and resist dirt.

Manufacturers use polished 6005 aluminum for fuel tanks, oil pipes, and liquid or gas conduits. These parts need to be shaped easily and joined by welding. The alloy’s good plasticity and weldability help with this.

You can find 6005 aluminum in sheet metal for vehicles and ships. It is also used for instrument cases, street lamp brackets, rivets, hardware, and electrical enclosures.

6005 aluminum alloy is easy to polish and works well for products that need both appearance and function. Its polished surface helps parts last longer and look better.

Mechanical properties:

| aluminum alloy | tensile strength(Rm)/MPa | Yield Strength(Rp0.2)/MPa | Elongation after fracture(A)/% | Hardness (reference value) |

|---|---|---|---|---|

| 6005-T5 | 260 – 270 | 215 – 240 | 8 – 10 | HW: about 15-15.3 |

| 6005-T6 | 270 – 304 | 225 – 264 | 10 – 13 | (HB)≤180 |

Metal composition:

| Chemical Element | % Present |

|---|---|

| Manganese (Mn) | 0.0 – 0.50 |

| Iron (Fe) | 0.0 – 0.35 |

| Magnesium (Mg) | 0.40 – 0.70 |

| Silicon (Si) | 0.50 – 0.90 |

| Zinc (Zn) | 0.0 – 0.20 |

| Titanium (Ti) | 0.0 – 0.10 |

| Chromium (Cr) | 0.0 – 0.30 |

| Copper (Cu) | 0.0 – 0.30 |

| Manganese + Chromium (Mn+Cr) | 0.12 – 0.50 |

| Other (Each) | 0.0 – 0.05 |

| Others (Total) | 0.0 – 0.15 |

| Aluminium (Al) | 98.9 and above |

Please note that the content ranges in this table are based on a general case 6005 aluminum alloy composition. However, actual production 6005 aluminum alloy compositions may be adjusted based on specific application requirements and manufacturer’s specifications.

Final Thoughts

6005 aluminum alloy offers strong performance and wide use. It resists rust and handles stress. Workers can weld and shape it with ease.

You will find 6005 aluminum in fuel lines, vehicle frames, ship parts, and electronic heat sinks. Its strength and corrosion resistance make it a popular choice.

As industries need better materials, 6005 aluminum alloy is ready for more roles in transport and shipbuilding. It is a reliable and practical metal with proven results.