What is 6060 Aluminum Extrusion?

6060 aluminum extrusion is a manufacturing process that shapes 6060 aluminum alloy into precise profiles. This alloy offers a balance of strength, formability, and corrosion resistance.

Key Properties of 6060 Aluminum:

- Medium strength, suitable for structural use

- High corrosion resistance, ideal for outdoor applications

- Excellent surface finish, supports anodizing and powder coating

- Good weldability and machinability

6060 aluminum extrusion delivers a reliable mix of strength, appearance, and versatility for many industries. If you need a material that adapts to different shapes and offers long-lasting performance, 6060 aluminum is a strong candidate.

Dimensions and Specifications of 6060 Aluminum Extrusion

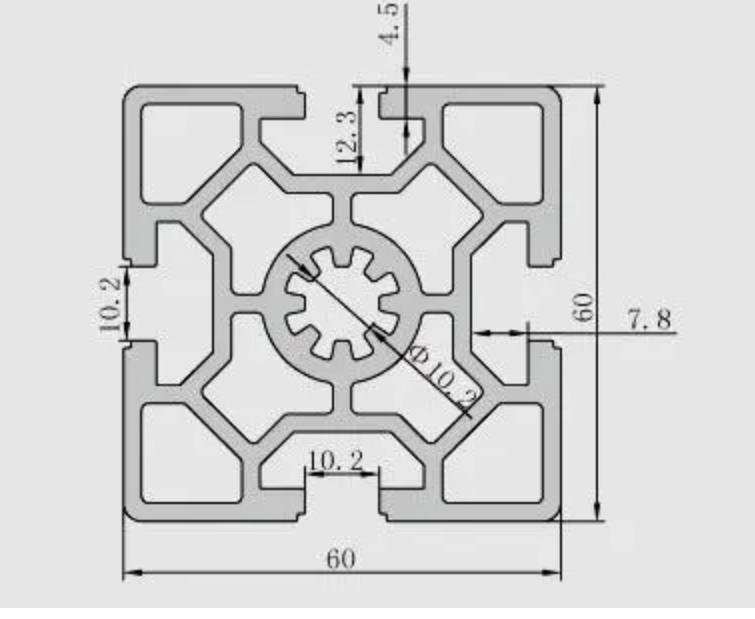

Cross-section and Slot Widths

6060 aluminum extrusion profiles have a standard cross-section of 60 x 60 mm.

These profiles come in two main slot widths:

- 8 mm slot width: Double-slot profiles, such as model 001.08.60.60, allow for multiple mounting options.

- 10 mm slot width: Single-slot profiles, including models 001.010.60.60L and 001.010.60.60W, provide strong support for heavier loads.

Choose the slot width based on the required accessory compatibility and load capacity.

Profile Types

Manufacturers offer three main types to suit different applications:

- Standard profiles: Suitable for most structural uses.

- Light profiles: Reduce weight for projects where lower mass is important.

- Heavy profiles: Increase rigidity for demanding, high-load environments.

Select the type based on the specific strength and weight requirements of your project.

Compatible Fittings and Fasteners

6060 aluminum extrusions use specific fittings and fasteners for secure assembly:

- External corner pieces: Connect profiles at right angles.

- 6060 T-bolts, 3030M8 bolts, M8 flange nuts: Standard connectors for reliable joints.

- 8 mm slot profiles: Use M8 cylindrical head bolts.

- 10 mm slot profiles: Use M12 cylindrical head bolts or special cross-fixing bolts in M8 or M12 sizes for extra stability.

Match the fastener size to the slot width for a secure fit and straightforward assembly.

Example Application

To build a machine frame that supports heavy equipment, select a 60 x 60 mm profile with a 10 mm slot and use M12 bolts. For lightweight shelving, use the 8 mm slot profile with M8 bolts to keep the structure streamlined.

Key Points

- Select profile and fastener types based on load and accessory needs.

- 6060 aluminum extrusion profiles measure 60 x 60 mm.

- Slot widths are 8 mm (double-slot) or 10 mm (single-slot).

- Profile options include standard, light, and heavy types.

- Assembly uses dedicated bolts and nuts matched to the slot width.

Advantages of 6060 Aluminum Extrusion

Strength and Durability

6060 aluminum extrusion provides high strength for its weight. The material resists bending and cracking under heavy loads. Its corrosion resistance protects against moisture and harsh environments.

- Withstands repeated stress without deforming

- Maintains structural integrity in outdoor and industrial settings

Processability and Versatility

Manufacturers can easily cut, drill, and shape 6060 aluminum. The alloy forms precise profiles and complex designs.

- Supports custom shapes and tight tolerances

- Adapts to both simple brackets and intricate frames

Application Range

6060 aluminum extrusion serves many industries. It supports equipment racks, production lines, and safety barriers. The material also appears in building facades, vehicle parts, and machinery housings.

- Used in manufacturing, construction, and transportation

- Fits projects that require both strength and design flexibility

Installation and Maintenance

Assembly uses standardized connectors and fasteners. Most builds require only basic tools. The material’s corrosion resistance reduces cleaning and repair needs.

- Fast installation with minimal equipment

- Low maintenance costs over time

Disadvantages of 6060 Aluminum Extrusion

Cost

6060 aluminum extrusion costs more than mild steel or standard plastics. This higher price can limit its use in projects with strict budgets.

- Raises material expenses for large-scale builds

- May not suit cost-sensitive applications

Performance at High Temperatures

6060 aluminum loses strength above 150°C (302°F). The material can deform or warp if exposed to sustained heat.

- Not suitable for equipment near ovens or engines

- Performs best in environments below high temperature thresholds

Example

A factory building conveyor frames near industrial ovens may see 6060 aluminum lose shape over time. In this case, stainless steel or titanium alloys offer better heat resistance.

Final Thoughts

6060 aluminum extrusion combines strength, stability, and corrosion resistance. These profiles come in multiple shapes and sizes, making them suitable for projects that need reliable support and fast assembly.

The material’s low weight reduces handling effort. Standardized connectors simplify installation. Corrosion resistance keeps surfaces clean and reduces maintenance.

Hugh Aluminum, based in China, supplies 6060 aluminum extrusions with 15 years of industry experience. The company offers extrusion, powder coating, anodizing, CNC machining, and product design. You can source high-quality, factory-direct profiles that match your project requirements and budget.