What is 7075 Aluminum Alloy? A Complete Guide

7075 aluminum is a high-strength alloy. Manufacturers make it using cold working and forging techniques. Zinc forms the main part of its structure. Magnesium and copper are present in smaller amounts.

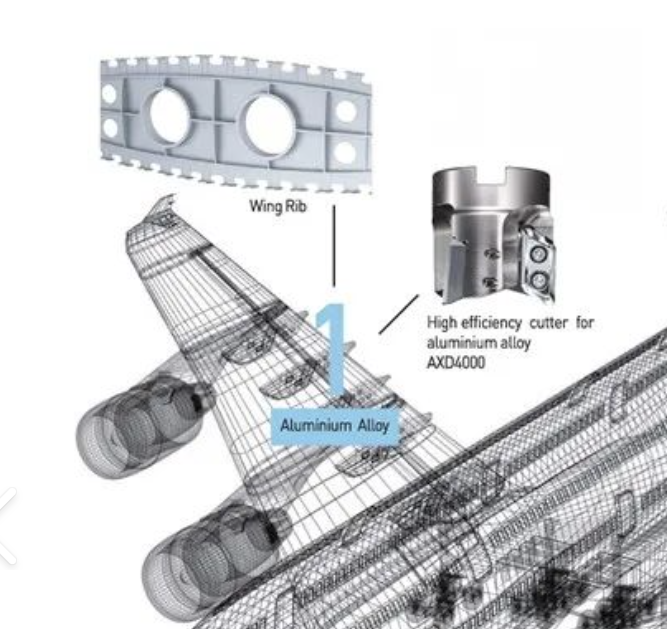

This alloy offers strong mechanical properties. It resists both stress and corrosion. Engineers use 7075 alloy aluminum in aerospace, cycling, and climbing gear.

7075 aluminum can handle tough tasks. Its performance remains stable under pressure. It also works well with anodizing processes for better durability and appearance.

If you want a material that stays strong and never quits, 7075 fits the bill. When strength matters, this alloy gets the job done.

Chemical Composition of 7075 Aluminum Alloy

7075 aluminum alloy contains mostly aluminum. Aluminum makes up over 90% of the material.

Zinc is the main alloying element after aluminum. The metal Zinc content ranges from 5.1% to 6.1%. It also increases the strength and hardness of the alloy.

Magnesium is present at 2.1% to 2.9%. Magnesium improves the strength and allows the metal to be machined more easily.

Copper is found in amounts from 1.2% to 2.0%. Copper adds strength and helps the alloy resist corrosion.

Chromium is a minor element, ranging from 0.18% to 0.28%. Chromium helps stabilize the alloy structure.

Small amounts of silicon, iron, manganese, and titanium are also present. Each of these elements is usually less than 0.5%. They help control the alloy’s final properties but do not make major changes.

Each element plays a role, working together like a reliable toolkit. With this lineup, 7075 alloy slides into demanding jobs and keeps its edge, mile after mile.

7075 Aluminum Alloy Processing Methods

7075 aluminum alloy uses a clear series of processing steps.

First, manufacturers use extrusion. They heat the alloy billet, push it through a die, and shape it into long pieces. This process gives parts a consistent cross-section.

Next comes heat treatment. Producers apply solution treatment and aging. These steps increase strength and hardness and help remove stress inside the metal.

The last step is surface treatment. Workers finish parts by anodizing, coating, or polishing them. These finishes protect the alloy from corrosion and can improve how it looks.

Every step takes 7075 alloy from raw metal to a ready part. Each stage plays a direct role in making sure the alloy meets demanding performance needs, with a finish that can catch the eye, too.

Advantages of 7075 Aluminum Alloy

7075 aluminum alloy offers several clear benefits.

It delivers high tensile and yield strength. This strength allows the alloy to support heavy loads and resist deformation.

7075 alloy remains lightweight. Its low density reduces the overall weight of parts while keeping their structure intact.

It resists corrosion. The material works well in wet or chemical environments without losing its integrity.

7075 machines easily. People can cut, drill, forge, and extrude it into different shapes. The alloy also accepts welding and riveting.

It maintains good toughness. The alloy absorbs shocks and vibrations, helping parts stay stable and reliable.

7075 aluminum alloy combines strength, low weight, corrosion resistance, easy machining, and toughness. These properties make it effective for demanding uses in aerospace, automotive, and sports equipment.

Final Thoughts

7075 aluminum alloy offers high strength and durability. Its production and material costs are higher than many other alloys.

Users should compare its performance benefits with their project budget. If your project demands toughness and reliability, 7075 alloy delivers. For less demanding uses, a lower-cost alloy may be a better choice.

Choose 7075 aluminum when you need strong, lightweight, and corrosion-resistant parts. Consider other alloys if minimizing cost is your top priority.