What are the Dimensions of the 3030 Aluminum Extrusion?

The 3030 aluminum extrusion has a square profile. Each side measures 30mm. The slots are 8mm wide. This makes the extrusion easy to use with standard connectors and fasteners. The core thickness is usually 2mm. This gives the profile enough strength for most projects.

You will find T-slots on all four sides. These slots allow you to attach parts or connect multiple extrusions. The design helps you build frames, machine guards, or workbenches with ease. You can cut the extrusion to any length you need. Assembly is simple and quick.

The 3030 profile is popular because it balances strength and flexibility. If you want a sturdy frame or a custom project, these dimensions make planning easier. Everything fits together well, like pieces in a puzzle.

The Basic Dimensions of 3030 Aluminum Extrusion

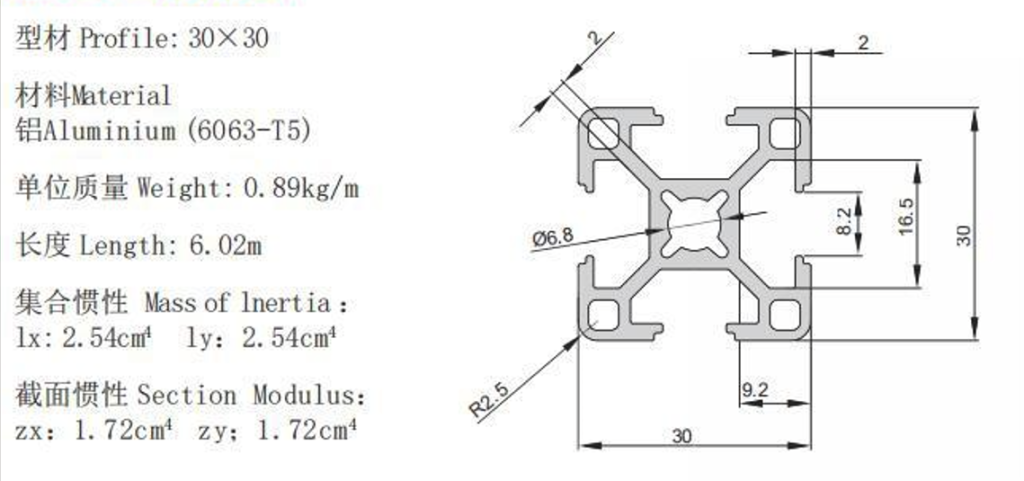

The 3030 aluminum extrusion has a square cross-section. Each side measures 30mm. This measurement gives the extrusion its name.

The standard length is 6 meters. Manufacturers can cut the extrusion to different lengths if needed.

The slot width is usually 8mm or 8.2mm. The extra 0.2mm helps with the easy installation of connectors and sliders.

Wall thickness ranges from 1.5mm to 2.2mm. Thicker walls increase strength and load capacity. For heavy-duty use, a wall thickness above 2.0mm is common.

The diagonal rib thickness is about 2.2mm. These ribs add strength and stability to the profile.

The center hole is round and measures 6.8mm in diameter. This hole allows for mounting bolts and other fasteners.

Every measurement serves a purpose. These dimensions make the 3030 aluminum extrusion reliable and easy to use for many projects.

3030 Aluminum Extrusion Size Details from Hugh Aluminum

The table below shows the main specifications for 3030 aluminum extrusion:

| Specification | Value/Description |

|---|---|

| Cross-section | 30 x 30 mm |

| Product length | 6 m (can be customized for different lengths) |

| Groove width | 8 mm or 8.2 mm (for accessory installation) |

| Wall thickness | 1.5 mm to 2.2 mm (varies by model and use) |

| Ramp thickness | 2.2 mm (adds strength and stability) |

| Center hole size | 6.8 mm (round, for bolts or fasteners) |

| Surface treatment | Powder coating or anodizing (for corrosion resistance and appearance; colors and patterns can be customized) |

| Material | 6063-T5 aluminum alloy (offers corrosion resistance) |

Let’s break it down:

- The cross-section is always 30mm by 30mm. That’s where the “3030” name comes from.

- The standard length is 6 meters, but you can order other lengths if your project calls for it.

- The groove width is either 8mm or 8.2mm. That little bit of extra space helps you fit connectors and sliders without a struggle.

- Wall thickness ranges from 1.5mm to 2.2mm. Thicker walls give the profile more strength.

- Ramp (or diagonal rib) thickness is 2.2mm, which helps keep everything sturdy.

- The center hole is 6.8mm in diameter. You use this for mounting bolts or fasteners.

- Surface treatment options include powder coating and anodizing. These finishes help prevent rust and let you pick a color or pattern that suits your style.

- The material is 6063-T5 aluminum alloy. This alloy is known for its corrosion resistance and good looks.

Every detail is there for a reason. Whether you’re building a frame, a guard, or something more creative, these specs help you get the job done right.

Other Information About 3030 Aluminum Extrusion

Surface Finish:

Manufacturers usually anodize 3030 aluminum extrusion. This process increases corrosion resistance and gives a clean appearance. Common colors are black and silver.

Material:

3030 aluminum extrusion uses 6063-T5 aluminum alloy. This alloy is strong and resists corrosion. It also provides a smooth surface.

These features help the extrusion last longer and look professional in any project.

Final Thoughts

The standard 3030 aluminum extrusion has a 30mm x 30mm cross-section. The usual length is 6 meters. The slot width is either 8mm or 8.2mm.

You can adjust these dimensions for special projects. Whether you need a longer piece or a different slot width, manufacturers can help you get the right fit.

In short, 3030 aluminum extrusion offers clear measurements and flexible options. It’s ready to support your next build – no guesswork required.