Aluminum Extrusion vs Fence Plants: Which One Fits Your Needs?

Aluminum extrusion plants and aluminum fence plants serve different purposes and produce distinct products.

Extrusion plants create aluminum profiles used in industries like construction, transportation, and electronics. Fence plants manufacture aluminum fencing designed for security, privacy, and decoration.

This article examines the differences between these two types of facilities. By the end, you’ll have a clear understanding of their unique roles and outputs.

Related products: Aluminum fence panels

Key Functional Differences Between Aluminum Extrusion and Fence Plants

Extrusions Plant

An aluminum extrusion plant produces aluminum profiles through processes like extrusion, cutting, and surface treatment. These profiles are raw materials or semi-finished products used in industries such as construction, transportation, and electronics.

The plant’s primary role is to supply materials for further manufacturing. Its products are not ready for direct use but serve as components for other applications.

Fence Plant

An aluminum fence plant manufactures finished aluminum fences. It uses aluminum profiles, often sourced from extrusion plants, and processes them through machining and assembly to create complete fencing systems.

The products from these plants are ready for end users, such as contractors, builders, and government projects. Unlike extrusion plants, fence plants deliver finished goods designed for immediate use.

Comparison of Product Features: Aluminum Extrusion vs Aluminum Fence Plants

Extrusion Plant

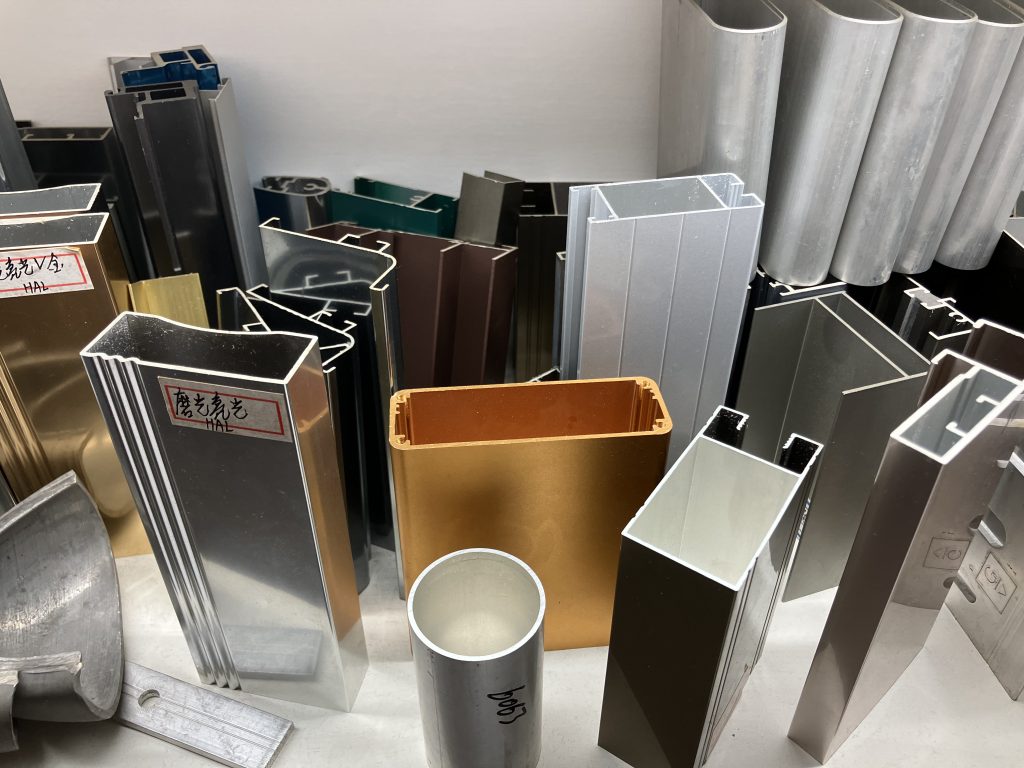

Aluminum extrusion plants produce aluminum profiles in various shapes and sizes. Examples include decking, window frames, door frames, and tubes. These profiles are lightweight, resistant to corrosion, strong, and versatile for different applications.

Surface treatments like anodizing and electrophoresis improve the durability and appearance of the profiles. These treatments allow the products to meet the specific requirements of industries such as construction, transportation, and electronics.

Fence Plant

Aluminum fence plants create finished fences for safety, separation, and protection. These fences use aluminum profiles processed and assembled into complete products.

The fences feature a simple design for easy installation. They also offer a visually appealing, clean, and attractive look, combining functionality with aesthetics. People commonly use these products for residential properties, commercial buildings, and industrial facilities.

Comparison of Step-by-Step Production Processes

Extrusion Plant

The production process begins with sourcing raw aluminum. Manufacturers extrude or stretch the material into specific shapes. Next, workers cut the profiles to the required sizes and apply surface finishes like anodizing or coating to improve durability.

After treatment, quality control teams inspect the products. Once approved, they package and ship the products to industries for further use. This process focuses on creating raw or semi-finished materials.

Fence Plant

The production process starts by procuring aluminum profiles, often from extrusion plants. Manufacturers machine and cut these profiles to meet fence design requirements. Then, they assemble the components into finished fencing products.

After assembly, the fences undergo quality checks to ensure they meet safety and aesthetic standards. Finally, the workers package the finished fences and deliver them to end users for immediate installation. This process produces ready-to-use products for homes, businesses, and public spaces.

Final Thoughts

Aluminum extrusion plants produce aluminum profiles from raw materials. Industries like construction, transportation, and manufacturing use these profiles as semi-finished products.

Aluminum fence plants take these profiles and turn them into finished fences. Through cutting, welding, and assembly, they create products ready for installation in homes, businesses, and public spaces.

To sum up, extrusion plants supply the raw materials, while fence plants deliver the final goods. Each plays a distinct role in the aluminum production chain.