How Strong Is Aluminum Extrusion?A Complete Guide

Aluminum extrusion is strong. If you want a quick answer, extruded aluminum can handle heavy loads without bending easily.

The strength of extruded aluminum depends on several factors. The type of aluminum alloy matters. Yield strength is a key measure. This is the stress level where aluminum starts to bend and does not return to its original shape. Most extruded aluminum profiles have a yield strength between 100 and 150 MPa.

The way aluminum is shaped also affects its strength. The extrusion process and the design of the cross-section both play a role. A simple change in shape can make a big difference in how much weight the aluminum can support.

The main factors that affect the strength of aluminum extrusion are:

- The grade and properties of the aluminum

- The extrusion process used

- The shape of the cross-section

- How aluminum is used in structures

Aluminum extrusion is a popular choice for many projects because it is both light and strong. Next, we will look at each factor in more detail to show why extruded aluminum performs so well.

Read more: How strong is 2020 aluminum extrusion?

Strength Factor of Aluminum Extrusion

Aluminum extrusion strength often means compressive strength. Compressive strength measures how much force aluminum can handle before it is crushed.

The alloy type affects compressive strength. Some alloys, like 7075, are much stronger than others. Heat treatment also increases strength. Treated aluminum can handle more pressure than untreated aluminum.

The extrusion process changes strength, too. The way aluminum is pushed through a die, the temperature, and the speed all matter. Careful control during extrusion creates stronger parts.

Most people use aluminum for its tensile strength and corrosion resistance. This means aluminum is often chosen for parts that need to stretch or resist rust, not just for parts that need to handle heavy pressure. Because of this, you will find more data on tensile strength than compressive strength.

Key factors that affect aluminum extrusion strength are:

- Alloy type

- Heat treatment

- Extrusion process

- Application needs

Aluminum extrusion can be strong enough for many uses. Always check the specific alloy and process details for your project. If you want aluminum that stands up to pressure, choose the right alloy and treatment. It’s a bit like picking the best player for your team – choose wisely, and you’ll get great results.

Material Grade and Characteristics

Alloy composition controls the strength of aluminum extrusion. Manufacturers add elements like silicon, iron, copper, magnesium, manganese, and chromium to pure aluminum.

The 6000 series aluminum uses silicon and magnesium. This combination creates light aluminum, resists corrosion, and has medium to high strength.

Some alloys get stronger after heat treatment. For example, 6061 and 7075 alloys become much stronger after quenching and aging. In contrast, alloys like the 1xxx series and 3A21 do not respond to heat treatment. These alloys remain soft and are used where high strength is not needed.

Choosing the right alloy and knowing if it can be heat-treated is important. The alloy and treatment decide how strong the final extrusion will be. Picking the right mix is like choosing the right player for a sports team – the results depend on your choice.

Influence of Aluminum Extrusion Process

Extrusion Temperature

Extrusion temperature sets how easily aluminum flows and shapes. The right temperature gives aluminum good formability and keeps its strength. If the temperature is too high, the aluminum gets too soft and loses strength. If the temperature is too low, the aluminum does not flow well and may crack. Most 6000 series alloys work best between 470°C and 500°C.

Extrusion Speed

Extrusion speed changes the quality of the aluminum profile. A slow speed can make the process uneven. A fast speed can overheat the aluminum and cause cracks or stress. A moderate, steady speed produces strong and even profiles.

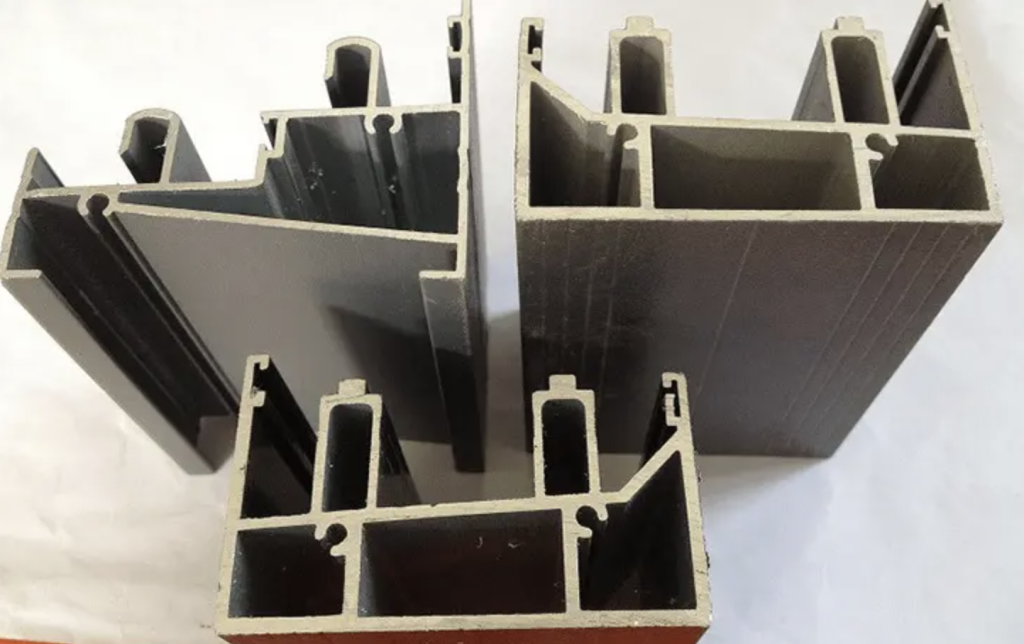

Die Design

Die design controls the final shape and strength of the extrusion. A well-designed die spreads stress evenly across the aluminum. This reduces weak spots and cracks. A poor die design can create stress points and lower the strength of the finished profile.

Pressure

Pressure helps the aluminum fill the die. The right pressure creates a solid, accurate shape. Too much pressure can damage the die or the aluminum. Too little pressure can leave gaps or weak areas in the profile.

The extrusion process shapes the final strength of aluminum profiles. Temperature, speed, die design, and pressure all play a part. Each factor needs careful control for the best results. When these steps work together, the finished aluminum profile is strong and reliable. Think of it like baking bread: the right mix and timing make all the difference.

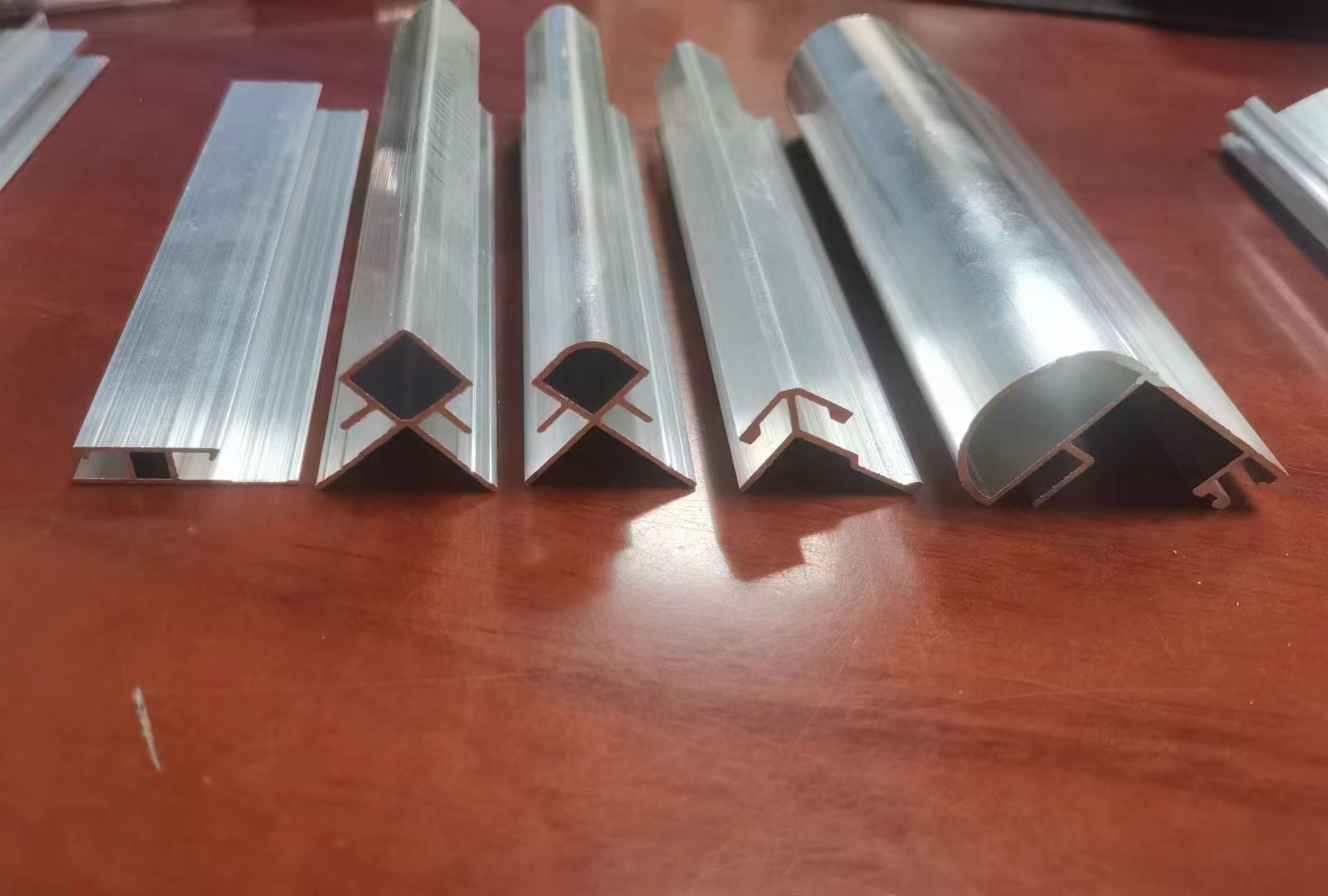

Influence of Extruded Aluminum Cross-Sectional Shape

Cross-Sectional Shape Design

The shape of an aluminum profile affects its strength. Rounded corners reduce stress and help prevent cracks. Sharp corners create weak points. Uniform wall thickness keeps the profile strong. Uneven walls can cause some areas to bend or break more easily. A well-designed shape helps the extrusion support more weight.

Cross-Sectional Size Tolerance

Size tolerance controls how much the actual profile can differ from the design. Tight tolerances keep strength and fit consistent, but can raise production costs. Loose tolerances make manufacturing easier but may create weak spots or poor fits. The best tolerance matches the needs of the product and the production process.

Structural Applications

Aluminum extrusions are used in many industries. Builders use them for window frames, door frames, and wall panels. The transportation industry uses them for body parts and wheels. Electronics and aerospace companies use them for lightweight, strong parts. People choose aluminum extrusions because they are light, strong, and resist corrosion.

A good cross-sectional design and the right tolerance make aluminum extrusions strong and reliable. A smart profile design helps the product last longer and perform better.

Final Thoughts

Aluminum extrusion strength depends on alloy, grade, cross-section size, and wall thickness. Your budget controls which options you can choose.

A higher budget lets you pick stronger alloys and thicker walls. In many cases, aluminum extrusion gives better strength-to-weight than steel.

Choose the right combination for your project. The right choice helps your structure last and perform well.