How to Cut Aluminum Extrusions Cleanly? Top Tools, Methods, and Pro Tips

Aluminum extrusion shapes aluminum alloys into long, precise profiles. The process heats an aluminum billet and pushes it through a die with a specific cross-section. This method creates parts used in window frames, electronics, and machinery.

Cutting aluminum extrusions is straightforward with the right tools and careful preparation. Follow these steps to achieve clean, accurate cuts every time.

Key Tips for Successful Cutting:

- Always check your measurements before cutting.

- Use sharp, clean blades to prevent rough cuts.

- Work in a well-lit area for better visibility.

Effective Cutting Methods for Aluminum Extrusions

Mechanical Cutting

Mechanical cutting uses a shear or saw blade to cut aluminum extrusions. This method relies on physical force.

Best Uses:

- Straight cuts with high accuracy

- Thin to medium aluminum profiles

Example:

A miter saw can quickly cut window frame sections with smooth edges.

Limitations:

Mechanical cutting does not handle curves or bends well. Use another method for complex shapes.

Thermal Cutting

Thermal cutting uses high heat from a plasma cutter or laser to separate aluminum.

Best Uses:

- Thick aluminum extrusions

- Projects needing narrow, precise cuts

Example:

A plasma cutter can slice through heavy-duty machine brackets quickly.

Safety Tips:

- Wear flame-resistant clothing

- Use safety goggles and gloves

- Keep a fire extinguisher nearby

Choosing the Right Method

- Use mechanical cutting for straight, clean cuts on thin profiles.

- Choose thermal cutting for thick materials or when speed is important.

- Always follow safety guidelines for each method.

Select the method that matches your project’s needs for the best results.

Which Saw Is Best for Cutting Aluminum Extrusions?

Selecting the right saw improves cutting accuracy and efficiency. The best choice depends on your project size, aluminum thickness, and desired cut quality.

Miter Saws

- Make precise straight and angled cuts.

- Works well for window frames and door tracks.

- Use a non-ferrous metal blade with a high tooth count for clean results.

Circular Saws

- Provide portable, straight cuts on long extrusions.

- Ideal for on-site work or quick adjustments.

- Use a carbide-tipped blade designed for aluminum.

Table Saws

- Offer stability for long or repeated cuts.

- Suitable for cutting multiple extrusions to the same length.

- Keep the extrusion firmly against the fence for best results.

Diamond Cutting Saws

- Cut thick or hard aluminum alloys with minimal blade wear.

- Used for heavy-duty or industrial applications.

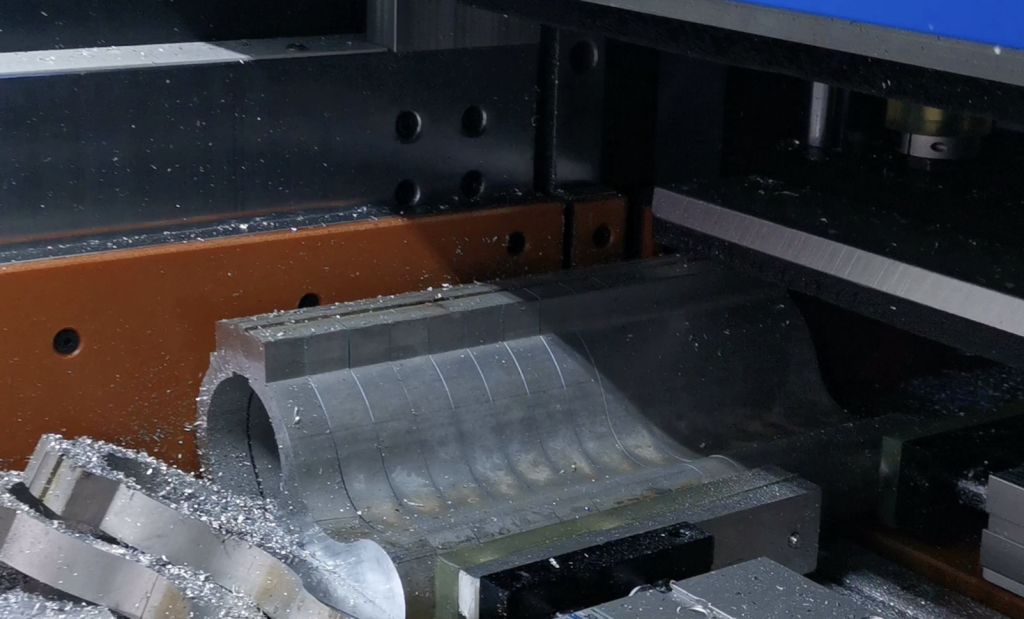

CNC Cutting Saws

- Deliver automated, high-precision cuts.

- Best for mass production or projects needing exact measurements.

Choosing the Right Saw

- Use a miter saw or circular saw for most home and workshop tasks.

- Choose a table saw for bulk cutting.

- Select a diamond or CNC saw for industrial or high-volume jobs.

Match your saw and blade to the aluminum extrusion and project needs for clean, accurate cuts. Always follow safety guidelines and secure your workpiece before cutting.

Step-by-Step Guide to Cutting Aluminum Extrusions Safely and Accurately

1. Set Up the Saw

- Install the correct blade for cutting aluminum.

- Check the blade for damage or dullness.

- Place the saw on a stable, dry surface.

- Keep the saw unplugged during setup.

- For CNC or motorized saws, enter the angle and length on the control panel. Confirm all settings.

2. Mark the Cut Line

- Measure the required length with a tape measure or caliper.

- Mark the cut line clearly with a marker or pencil.

- Double-check your measurement for accuracy.

3. Clamp the Workpiece

- Align the blade’s longest tooth with the waste side of the cut line.

- Secure the extrusion with a clamp or jig.

- Test the clamp by gently moving the extrusion to confirm it is tight.

4. Make the Cut

- Plug in the saw.

- Lower the blade slowly and let it cut without forcing.

- Unplug the saw after cutting.

- Remove and measure the finished piece.

- Use an air gun to clear away aluminum chips.

5. Clean Up

- Vacuum or sweep up aluminum shavings.

- Remove and clean the saw blade.

- Dispose of sharp off-cuts safely.

Follow these steps for clean, accurate cuts and a safe workspace.

Precautions for Cutting Aluminum Extrusions

Wear Safety Gear

- Use safety goggles to protect your eyes from metal chips.

- Wear gloves to prevent cuts.

- Use hearing protection to reduce noise exposure.

- Wear long sleeves and closed-toe shoes for added safety.

Control Cutting Parameters

- Set the cutting speed and pressure to match the aluminum thickness.

- Adjust the cutting angle for clean, accurate edges.

- Move the saw steadily to avoid rough cuts or blade damage.

Maintain Tools Regularly

- Inspect saw blades before each use.

- Replace dull or damaged blades immediately.

- Clean and lubricate saw components to extend tool life.

Follow these steps to keep your workspace safe and your cuts precise. Proper safety and maintenance help you avoid injuries and improve cutting results.

Final Thoughts

Cutting aluminum extrusions requires the right tools and careful technique. Use accurate measurements, secure your workpiece, and follow safety steps for the best results.

For large orders or oversized profiles, contact a professional service. Hugh Aluminum has 14 years of experience and offers precision-cut aluminum extrusions in many styles.

If you need custom sizes or bulk production, our team can help you get the exact profiles you need. Reach out for expert advice or a quote on your next project.