Extruded Aluminum Electronic Enclosures

| Item | Details |

|---|---|

| Product Name | Extruded Aluminum Enclosure |

| Material | Aluminum alloys: 6063, 6005, 6005A, 6061 |

| Types Available |

1. Aluminum Instrument Enclosures 2. Aluminum Power Supply Enclosures 3. Aluminum Protective Enclosures 4. Custom Aluminum Enclosures |

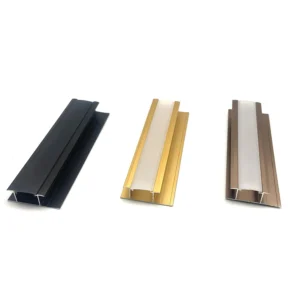

| Standard Colors & Finishes | White, gray, black, silver, mill finish, matte black |

| Custom Colors | Hundreds of additional color options available |

| Fabrication Services | Enclosure design, extrusion, cutting, drilling, welding, CNC machining, punching, polishing |

| Surface Treatments | Anodizing, mill finish, electroplating, polishing, powder coating, wood grain, blasting, hard coating, PVDF |

| OEM / ODM | Available |

| Quality Control | ISO 9001 certified |

| Minimum Order Quantity | 300 pieces |

| Payment Terms | Arranged with sales team via email |

Your electronics deserve strong protection. Our extruded aluminum enclosures provide it.

We use a precision extrusion process to shape aluminum into durable housings. Each enclosure shields your components from dust, impact, and spills.

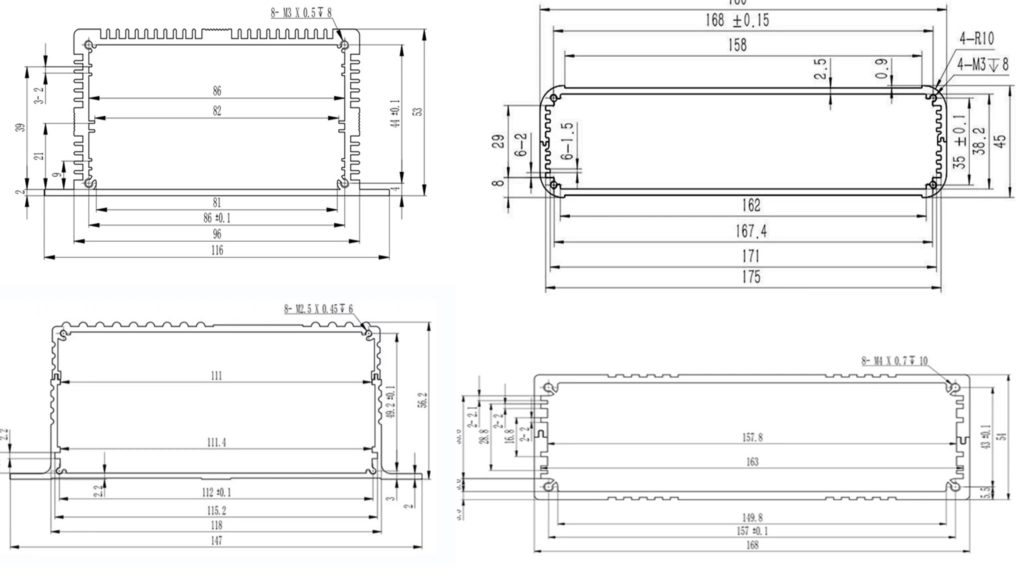

Sizes vary to fit small circuit boards, LED power supplies, and larger control units. The aluminum keeps the weight low while adding strength.

If you need equipment protection at home, in the office, or on the road, these enclosures work. They are solid, light, and easy on the eyes.

Top Features: Why You’ll Love Our Extruded Aluminum Enclosures

Light and Strong – Aluminum has a density of 2.7 g/cm³. It delivers high strength without adding weight. Ideal for portable devices and weight-sensitive projects.

Corrosion Resistant – A natural oxide layer protects against moisture, salt, and chemicals. Suitable for marine, outdoor, and industrial use.

Efficient Heat Control – Thermal conductivity of about 200 W/m·K moves heat away quickly. Larger surface areas or heat sink profiles boost cooling for high-power equipment.

Durable Structure – The extrusion process spreads stress evenly. This increases rigidity and helps the enclosure withstand impacts, pressure, and constant vibration.

Easy to Modify – Aluminum cuts, drills, and welds with ease. The extrusion method supports various sizes and shapes to match specific design needs.

EMI Protection – Conductivity blocks electromagnetic interference. This keeps communication devices and high-frequency electronics operating without disruption.

Applications of Extruded Aluminum Enclosures

Electronics Protection – These enclosures protect computers, televisions, and sound systems. They also move heat away from internal components to maintain performance.

Industrial and Mechanical Use – They serve as housings that block dust, water, and impact in machinery and control equipment.

Communication Gear – They cover and shield circuit boards in network devices and communication terminals. This helps keep signals stable and connections reliable.

Household Appliance Shells – They protect internal parts in refrigerators, air conditioners, and other appliances. They help control temperature and prevent damage from moisture or sudden heat changes.

Lightweight, strong, and built to take a hit — extruded aluminum enclosures keep your electronics safe wherever they work.

Reviews

There are no reviews yet.