How to Remove and Prevent Rust on Aluminum Tubes? Complete Guide

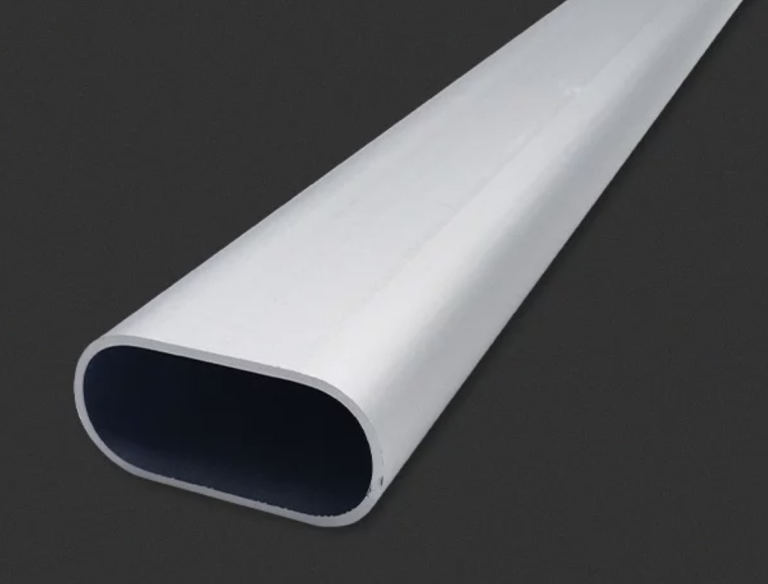

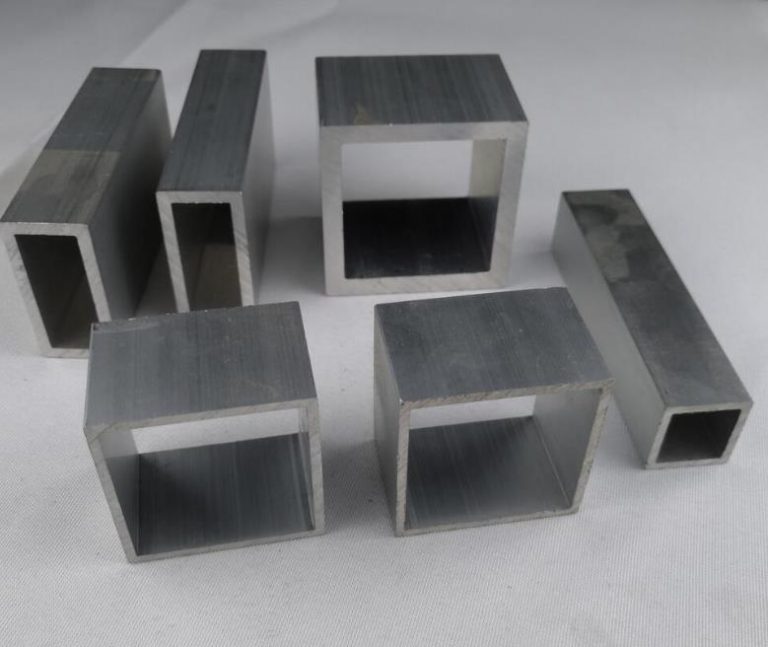

Aluminum tubes, also called aluminum pipes, are made by forcing aluminum through a shaped mold. This process creates tubes in many forms, such as round, square, and rectangular. You can find these tubes in buildings, vehicles, and ships.

Aluminum resists corrosion and is light but strong. These qualities make it a popular choice for many uses. However, aluminum can still rust under certain conditions. This may seem odd, but it happens. Let’s explore why aluminum rusts and how you can prevent it.

Why Does Aluminum Tubing Rust?

Aluminum resists corrosion by forming a thin layer called aluminum oxide when it comes into contact with oxygen. This layer is very thin, about one ten-thousandth of a millimeter.

This layer can wear away or get damaged over time. When that happens, the aluminum underneath can rust.

Strong acids and alkalis can damage this protective layer quickly. Scratches on the surface also let rust form. Aluminum fights rust well but needs care to stay protected.

Best Ways to Stop and Fix Rust on Aluminum Tubes

Aluminum tubes resist rust, but problems can still happen. Here are clear steps to fix and prevent rust on aluminum tubes:

1. Clean with Detergent

Use a mild cleaner to wash dirt and oil from the tube. Wipe stains with a soft cloth. Rinse with water. This method works for light rust.

2. Acid Wash

Soak the corroded tube in an acid solution for a few minutes. Rinse well after soaking. Strong acids can harm skin, so let professionals handle this. Use this method for moderate or heavy rust.

3. Repair with Epoxy

Spread epoxy adhesive on small rust spots. The epoxy blocks moisture and adds strength. This fix works for minor corrosion.

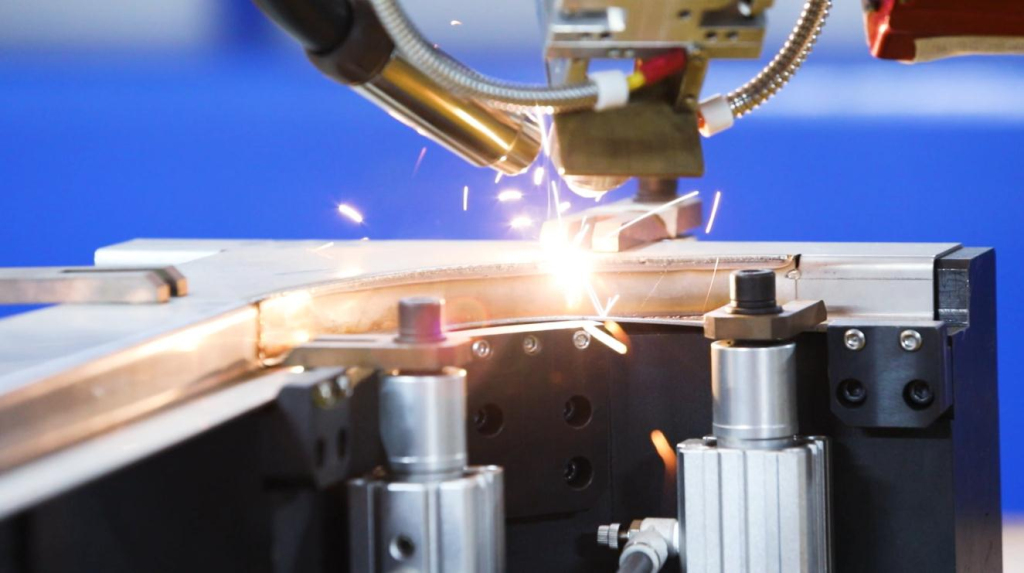

4. Weld Damaged Areas

Use welding to repair large, rusted sections. Melt and reshape the metal. Do not use this method for tubes that support heavy loads, as welding can weaken the metal.

5. Replace the Tube

If rust covers most of the tube, replace it. Repairs will not last if over 80% of the surface is damaged. New tubes restore safety and function.

6. Add Surface Coating

Apply anodizing, powder coating, or paint to protect the tube. These coatings block moisture and chemicals. Coated tubes last longer. If you use plain aluminum, expect to clean and maintain it more often.

Final Thoughts

Check aluminum tubes often. Clean them to remove dirt and moisture. Fix rust early with the right method. Use coatings for extra protection. Replace tubes if damage is severe. Simple steps keep aluminum tubes strong and ready for use.