What is 3030 Aluminum Extrusion?

The 3030 aluminum extrusion is a metal profile with a square cross-section measuring 30mm by 30mm. Each side has a slot, so you can attach bolts, screws, or connectors with ease. Builders use this profile to create frames, workstations, and machine enclosures. Its design allows for quick assembly and easy adjustments. Think of it as a building block for industrial projects – simple, strong, and adaptable.

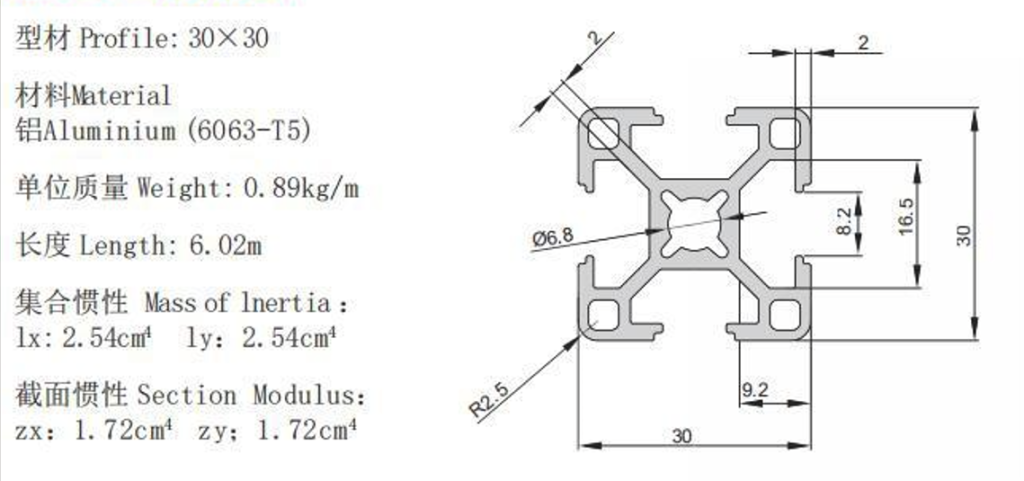

3030 Specifications and Types

The 3030 aluminum profile is available in different wall thicknesses. Common options include 2.2mm and 1.8mm. Some profiles use thinner walls, such as 1.5mm or 1.1mm. Most 3030 profiles come in 6-meter lengths. Manufacturers can cut the profile to any length you need.

Some models have small differences in slot width or surface finish. Heavy-duty versions work well for large structures. Lighter versions fit smaller projects. Choose the type that matches your needs, and you are ready to build.

Features of 3030 Aluminum Extrusion

1. High Strength – 3030 aluminum holds heavy loads. Its frame keeps structures stable and safe.

2. Lightweight – This profile weighs less than steel. People can move and install it easily. Lighter weight speeds up assembly.

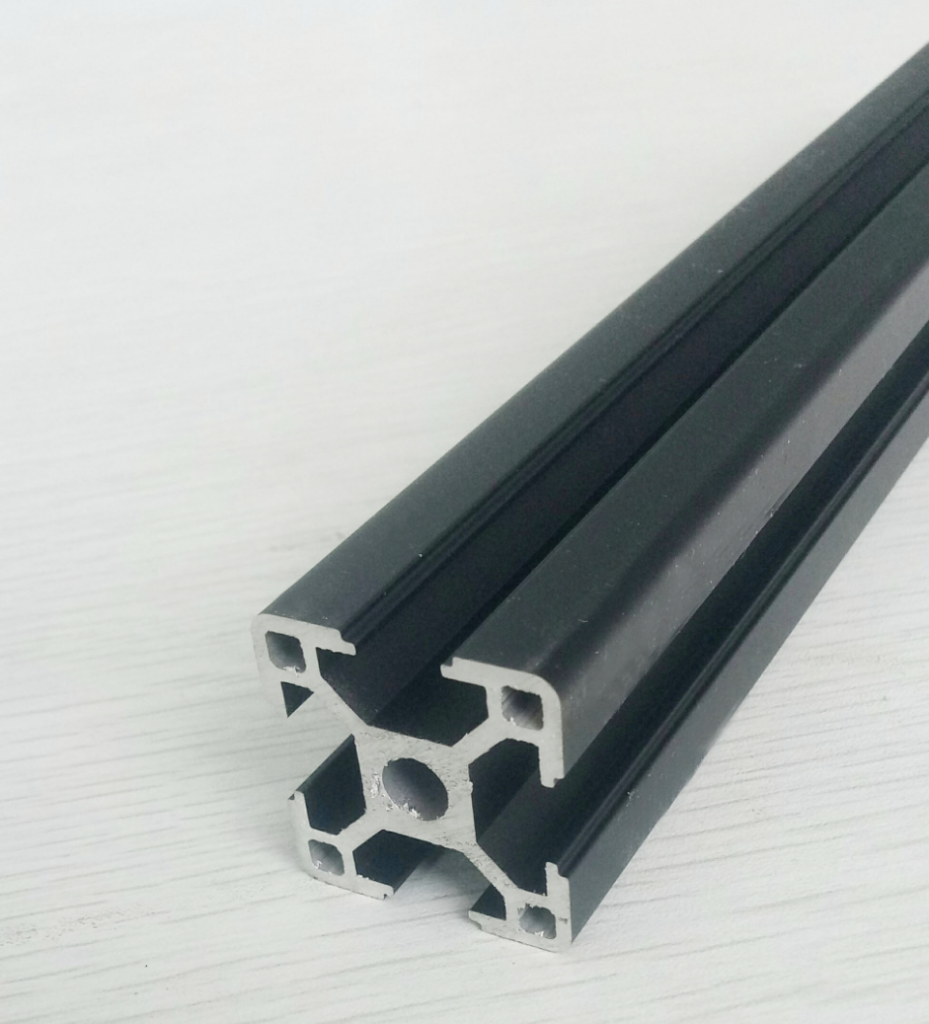

3. Corrosion Resistance – Anodized aluminum resists rust and oxidation. It works well in wet or humid places and lasts longer without much upkeep.

4. Easy Expansion – Grooves on each side allow you to attach bolts and nuts anywhere. You do not need to weld. You can add or move parts quickly by sliding in connectors.

These features make 3030 aluminum a smart choice for strong, light, and flexible projects.

Common Uses and Applications

1. Small Frame Products – People use 3030 extrusion to build small frames. Common examples include material racks, display stands, and poster holders. These frames are lighter than those made with larger profiles.

2. Home Products – 3030 aluminum supports home projects. It works well for fish tank stands, washing machine shelves, and plant trellises. Its size and finish fit home spaces, and it resists rust.

3. Workbench and Whiteboard Shelves – Factories use 3030 aluminum extrusion for workbenches and whiteboard stands. These benches serve one person and help with tasks like assembly or inspection. Whiteboard racks hold boards for notes and move easily around the workspace.

3030 aluminum extrusion gives builders a simple and flexible way to create many types of structures.

Final Thoughts

3030 aluminum extrusion has a 30x30mm cross-section. It gives high strength and low weight. People use it for workbenches, fish tank stands, and display racks.

Hugh Aluminum makes aluminum extrusions in China. The company offers extrusion, powder coating, anodizing, CNC machining, and polishing. Hugh Aluminum has 15 years of experience with T-slot profiles like 2020, 3030, 4040, and 5050.

3030 aluminum extrusion is a practical choice for many building projects. It is simple, strong, and easy to use.