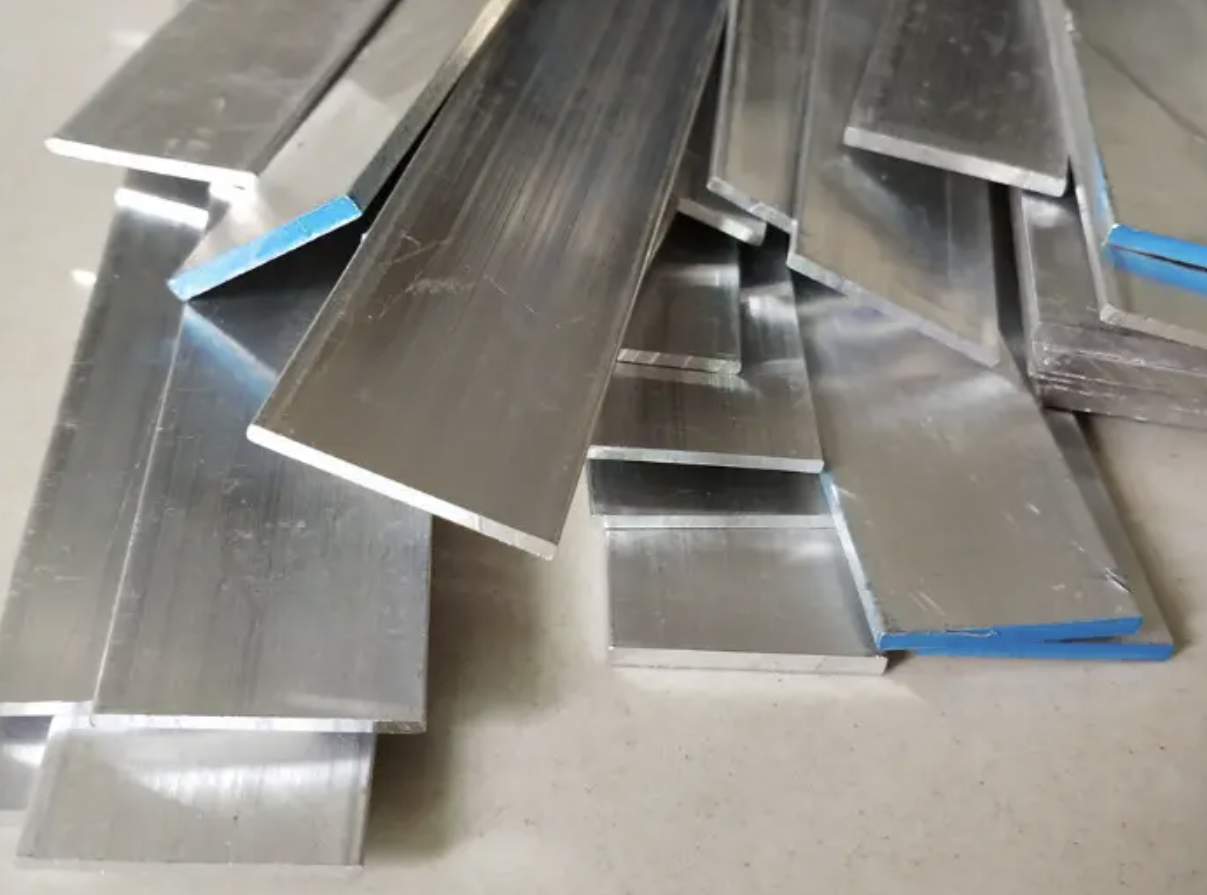

What is 5052 Aluminum Alloy?

5052 aluminum alloy resists rust. This alloy belongs to the aluminum-magnesium group. Manufacturers use 5052 when they need metal that fights corrosion and shapes easily. It offers medium strength and good workability. You will find 5052 in boat hulls, fuel tanks, and signs. Its combination of durability and flexibility makes it a popular choice for many industries.

Chemical Composition of 5052 Aluminum Alloy

5052 aluminum alloy contains several key elements:

- Aluminum (Al): This is the main component.

- Magnesium (Mg): 2.2% to 2.8%. Magnesium increases strength and helps prevent corrosion.

- Chromium (Cr): 0.15% to 0.35%. Chromium supports grain stability.

- Copper (Cu): Up to 0.10%. Copper content stays low to avoid rust.

- Silicon (Si): Up to 0.25%. Silicon helps with shaping the alloy.

- Manganese (Mn): Up to 0.10%. Manganese adds a bit more strength.

- Zinc (Zn): Up to 0.10%. Zinc levels are kept low.

- Iron (Fe): Up to 0.40%. Iron is present in small amounts.

Each element has a specific role. Together, they give 5052 aluminum its strength, flexibility, and resistance to rust. In short, these ingredients make 5052 a reliable choice for many uses.

Key Benefits of 5052 Aluminum Alloy

1. Corrosion Resistance – 5052 aluminum resists corrosion, especially in saltwater. Many marine products use this alloy for its long-lasting surface.

2. Forming Performance – 5052 shapes easily. Manufacturers can cold head, machine, or weld it into different forms.

3. Welding Performance – 5052 supports many welding methods, including gas welding, arc welding, resistance welding, spot welding, and seam welding. Argon arc welding may cause cracks, so welders should monitor the process closely.

5052 aluminum alloy offers strong corrosion resistance, easy shaping, and flexible welding options. These qualities make it a top pick for many industries.

Physical Properties and Mechanical Strength

- Tensile strength: 173 to 244 MPa. 5052 alloy can handle strong pulling forces.

- Yield strength: At least 70 MPa. The alloy keeps its shape under stress.

- Elongation: 18% or higher. It stretches before breaking.

- Density: About 2.68 g/cm³. This alloy is lightweight.

- Thermal conductivity: Around 160 W/(m·K). It transfers heat efficiently.

- Specific heat capacity: About 890 J/(kg·K). It takes time to heat up.

5052 cannot be strengthened by heat treatment. Cold working, such as bending or rolling, can increase its strength. If you want this alloy to work harder, give it a little push—don’t turn up the heat.

Common Applications

- Aerospace: 5052 alloy is used for aircraft fuselages, fuel tanks, and body panels. This alloy helps reduce weight and maintain strength.

- Automotive: Car manufacturers use 5052 for body panels, doors, and hoods. The alloy lowers vehicle weight and improves fuel efficiency.

- Shipbuilding: Shipbuilders use 5052 for hulls, cabins, and flybridges. The alloy resists corrosion in saltwater.

- Petrochemical: 5052 is used in storage tanks, pipelines, and heat exchangers. It handles chemicals and pressure well.

- Home Appliances: Appliance manufacturers use 5052 for TV back panels, computer heat sinks, refrigerator doors, and air conditioner shells.

5052 aluminum supports many industries by offering lightweight, strength, and resistance to corrosion.

Final Thoughts

5052 aluminum alloy offers corrosion resistance, good formability, and medium strength. Many industries use this alloy for reliable performance.

Hugh Aluminum manufactures aluminum extrusion products in China. We produce 5052 aluminum alloy products. If you want to buy 5052 aluminum alloy or have questions, please contact us. We are ready to help.