What is 6000 Series Aluminum Extrusion?

6000 series aluminum extrusion is a common material in construction and manufacturing. This alloy mixes aluminum with magnesium and silicon. The result is a material that is strong, light, and easy to shape.

6000 series aluminum is popular because it offers good strength and resists rust. You can heat-treat it to make it even stronger. It is easy to cut, weld, and form into different shapes. This makes it useful for products like window frames, doors, ladders, and railings.

Manufacturers choose 6000 series aluminum because it is reliable and flexible. It works well for both indoor and outdoor projects. The material stands up to weather and daily use, so it lasts a long time.

This alloy is a reliable choice for projects that need a material that is strong, easy to form, and long-lasting.

Metal Composition

6000 series aluminum extrusion contains three main elements: aluminum, magnesium, and silicon. Magnesium and silicon combine to form magnesium silicide, which gives the alloy its strength and hardness.

Manufacturers may add small amounts of copper, manganese, iron, chromium, or zinc. These extra elements help improve certain properties.

Most 6000 series alloys have about 0.6–1.2% magnesium and 0.4–1.5% silicon. Aluminum makes up the largest part of the alloy.

This mix creates a material that is strong, easy to shape, and resists corrosion. That’s why you see it used in so many products, from window frames to bike parts.

Characteristics of 6000 Series Aluminum

- Density

6000 series aluminum has a density between 2.6 and 2.8 g/cm³. This low weight makes it useful for lightweight designs. - Strength

This alloy reaches medium to high strength. 6061 aluminum, for example, is strong and welds well. - Corrosion Resistance

6000 series aluminum resists rust and oxidation. It performs well in wet, salty, or chemical environments. - Machinability

You can cut, stamp, extrude, and weld this alloy easily. 6063 aluminum shapes well and accepts coatings. - Thermal Conductivity

This alloy transfers heat efficiently. It works well in electronics and engines that need good heat dissipation. - Weldability

6000 series aluminum welds easily. The 6061 alloy is a popular choice for welding projects. - Anodizing

You can anodize 6000 series aluminum to add a protective oxide layer. This process increases corrosion resistance.

These features make 6000 series aluminum a practical choice for construction, vehicles, and electronics. It is strong, light, and easy to use.

Applications of 6000 Series Aluminum

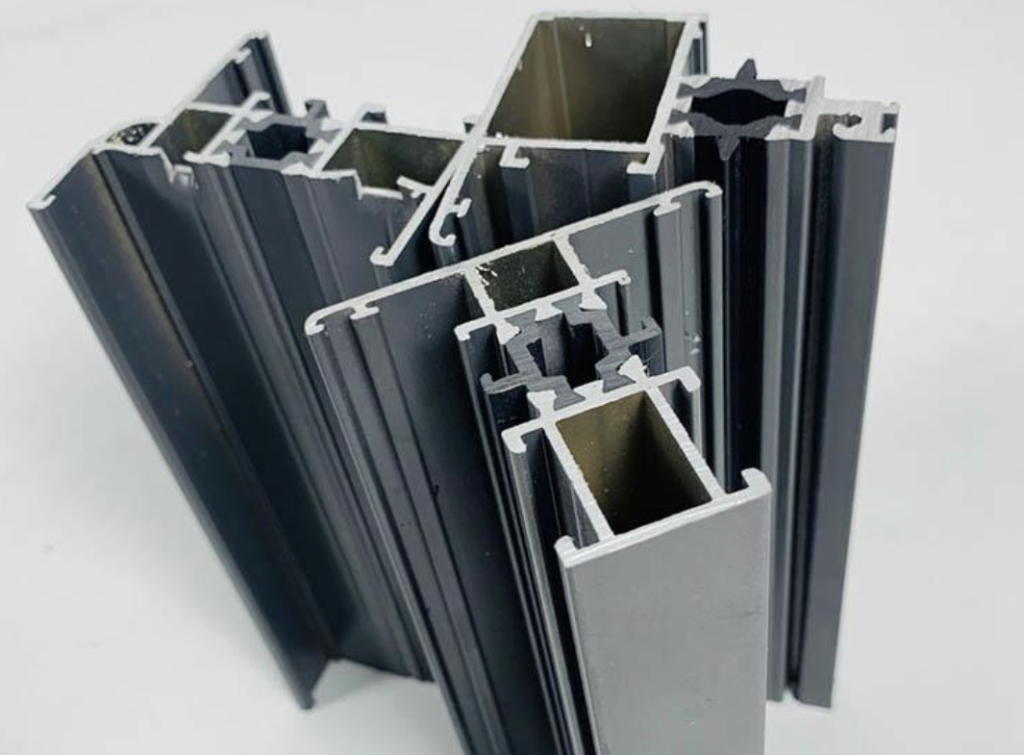

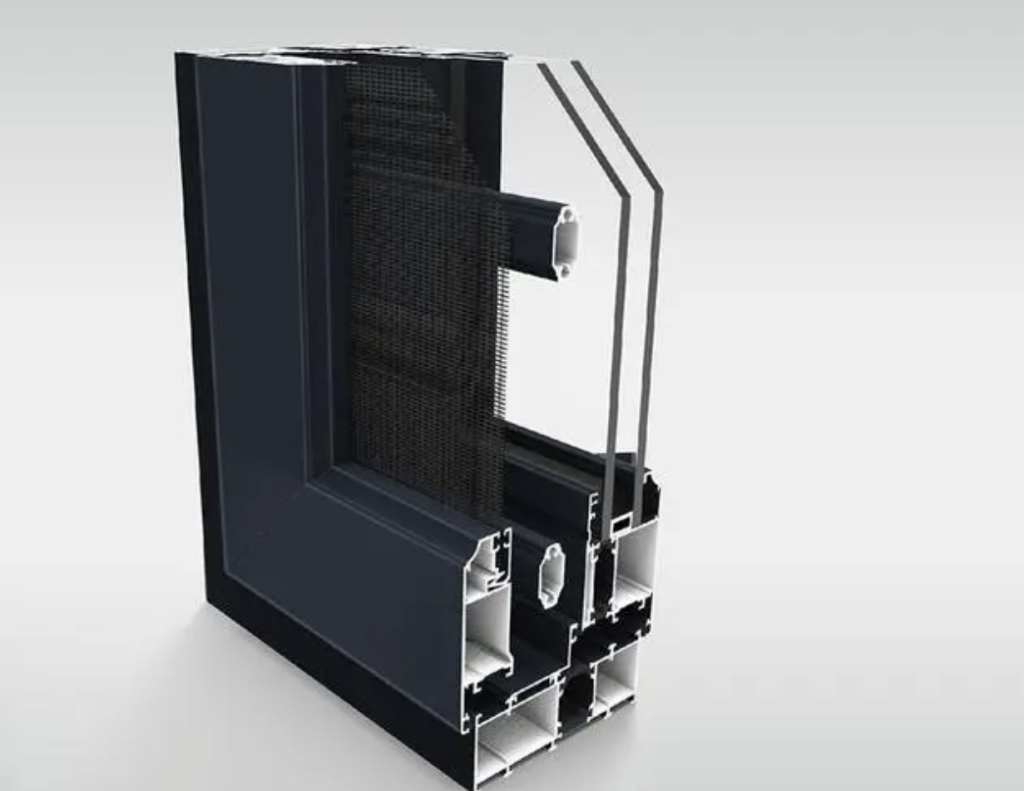

Building Doors and Windows

Manufacturers use 6063 aluminum alloy to make frames and blades for doors and windows. This alloy shapes and welds easily.

Aluminum profiles have a density of about 2.7 g/cm³. This low weight reduces the load on buildings.

Aluminum resists rust and moisture. This property helps doors and windows last longer.

6063 aluminum keeps doors and windows light, strong, and reliable. It is a common choice for modern construction.

Curtain Wall Materials

Manufacturers use 6061 aluminum alloy for curtain wall frames and decorative strips. This alloy supports large glass panels and shapes easily. It keeps its appearance and resists weather damage.

Heat Sinks

6061 aluminum is a common material for heat sinks. It resists corrosion and forms into many shapes. Aluminum heat sinks cost less than copper ones and work well in electronics and cars.

Guardrails and Fences

6063 aluminum alloy is used for railings and fences. You can powder coat or anodize this alloy for extra protection and color. Builders use 6063 aluminum for balcony railings and garden fences because it holds up in outdoor conditions.

6000 series aluminum is strong, easy to shape, and useful in many products. It is a practical choice for both buildings and equipment.

Grade 6063 Aluminum

Manufacturers use 6063 aluminum for most extruded products in the 6xxx series. They make door frames, window frames, channels, and building structures from this grade.

You see 6063 aluminum in homes, offices, and shops. It provides a smooth finish and shapes easily.

If you open a window or lean on a balcony rail, you likely touch 6063 aluminum. This grade is common in everyday building materials.

Advantages of Grade 6063 Aluminum

Corrosion Resistance

6063 aluminum resists oxidation and corrosion. It works well in humid, hot, and salty environments. Builders use it for docks and marine structures because it lasts in tough conditions.

Plasticity

6063 aluminum is the softest in the 6xxx series. Manufacturers shape it into complex profiles for windows, doors, and trims.

Cold Forming

6063 aluminum bends and folds easily, especially in the T4 temper. It is a good choice for bent tubes and curved parts.

This grade offers strength, flexibility, and long service life in many settings.

Chemical composition of 6063 grade:

| element | content% |

|---|---|

| aluminum(Al) | 95.85% – 98.56% |

| silicon(Si) | 0.20% – 0.66% |

| iron(Fe) | ≤ 0.35% |

| copper(Cu) | ≤ 0.10% |

| manganese(Mn) | ≤ 0.10% |

| magnesium(Mg) | 0.45% – 0.99% |

| chromium(Cr) | ≤ 0.10% |

| zinc(Zn) | ≤ 0.10% |

| titanium(Ti) | ≤ 0.10% |

Grade 6082 Aluminum

Grade 6082 aluminum is the hardest alloy in the 6000 series. It contains the most silicon among these alloys.

Manufacturers use 6082 aluminum for parts that need high strength. You find it in weapons, military gear, and aircraft components. This grade performs well in demanding applications.

Advantages of Grade 6082 Aluminum

High Strength

6082 aluminum has high strength. Heat treatment increases this strength further. Engineers use it for satellites, airplanes, and car parts that need strong, light materials.

Machining

6082-T6 aluminum is easy to machine. You can cut, drill, and shape it with standard tools. This grade is a good choice when you need precise and strong aluminum parts.

Chemical composition of 6082 grade:

| element | content % |

|---|---|

| aluminum(Al) | 98.3%-95.4% |

| silicon(Si) | 0.7% – 1.3% |

| magnesium(Mg) | 0.6% – 1.2% |

| manganese(Mn) | 0.4% – 1.0% |

| chromium(Cr) | ≤ 0.25% |

| copper(Cu) | ≤ 0.10% |

| zinc(Zn) | ≤ 0.20% |

| titanium(Ti) | ≤ 0.10% |

| iron(Fe) | ≤ 0.50% |

Grade 6061 Aluminum

Grade 6061 is a medium-strength aluminum alloy. Manufacturers produce it mainly for the U.S. market.

Grade 6082 is similar to 6061 but usually costs more. The performance difference between them is small.

6061 aluminum is a strong and cost-effective choice for many projects.

Physical Properties of Grade 6061 Aluminum

- Density: 2.75 g/cm³

- Poisson’s Ratio: 0.33

- Yield Strength: Over 110 MPa

- Elongation: 16% or more

- Tensile Strength: 150–290 MPa

Heat Treatable

6061 aluminum is a heat-treatable alloy. Heat treatment increases its strength and hardness. 6061-T6 has a hardness close to grade 6082. After heat treatment, 6061 reaches its maximum strength.

Chemical composition of 6061 grade:

| element | content % |

|---|---|

| aluminum(Al) | 98.5%——99.2% |

| silicon(Si) | 0.40%——0.80% |

| copper(Cu) | 0.15%——0.40% |

| magnesium(Mg) | 0.80%——1.20% |

| Zinc(Zn) | 0.25% |

| manganese(Mn) | 0.15% |

| chromium(Cr) | 0.04%——0.35% |

| titanium(Ti) | 0.15% |

| Iron(Fe) | 0.70% |

Final Thoughts

6000 series aluminum alloys combine strength, workability, and corrosion resistance. Builders use them widely in construction projects.

These alloys handle tough jobs and keep their shape over time. If you want a metal that is light, strong, and easy to work with, 6000 series aluminum is a smart pick for almost any structure.