What is 6061 Aluminum Alloy? A Complete Guide

6061 aluminum alloy is a widely used material made from aluminum mixed with magnesium and silicon. It has medium strength, resists corrosion well, and can be welded or machined with ease.

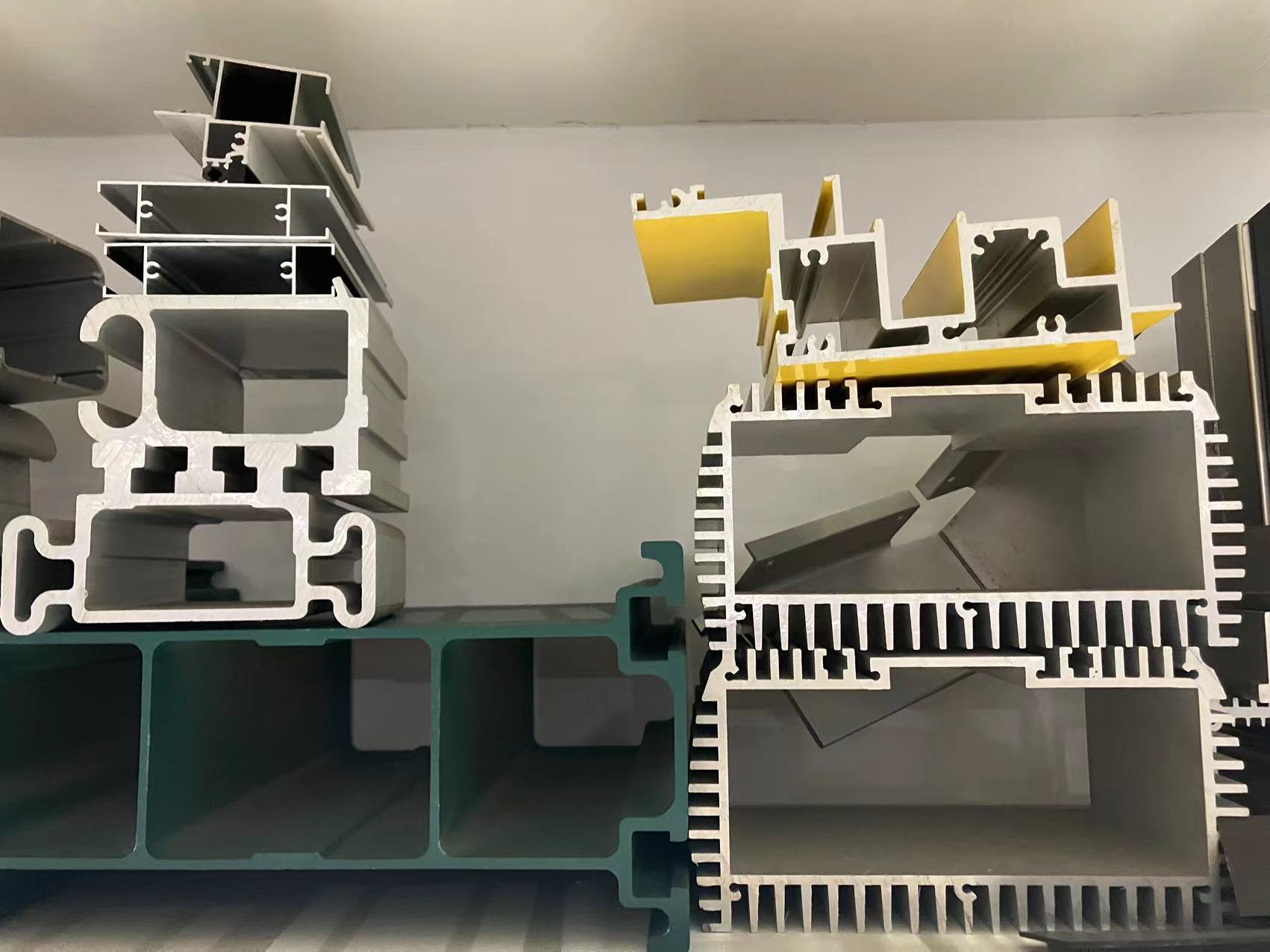

Engineers and manufacturers prefer 6061 because it performs consistently across different applications. It is commonly shaped through aluminum extrusion and heat treatment, both of which improve its mechanical properties. These processes make the alloy stronger while keeping it easy to form.

After heat treatment, 6061 maintains good weldability and machinability. Even after annealing—where the metal is softened for further use—it remains easy to cut, bend, and reshape.

You’ll find 6061 in bike frames, aircraft parts, car components, and hobby projects. It’s strong without being heavy, simple to work with, and holds up well over time.

Properties and Advantages of 6061 Aluminum

6061 aluminum resists corrosion well. Its natural oxide layer gives protection against moisture and chemicals. This quality makes it reliable outdoors and in contact with various substances.

You can weld 6061 aluminum using common methods like MIG and TIG. The material connects easily without losing strength. This allows for repairs or custom builds without special effort.

Machining 6061 aluminum is straightforward. You can cut, drill, stamp, and mill it with standard tools. The alloy produces smooth cuts and holds shape, which helps in precise manufacturing.

Forming 6061 aluminum into different shapes is possible through heat and pressure. Heat treatment improves formability, so you can bend or mold it for many applications. The alloy adapts to project needs without cracking.

Ultimately, 6061 aluminum simplifies manufacturing and stands up to tough conditions. It brings flexibility, durability, and ease of use, making it a favorite for engineers and creators alike.

Applications of 6061 Aluminum

6061 aluminum serves many industries. This alloy appears in machines, sports equipment, solar energy systems, and electronics. Its lightweight and strength make it useful across these areas.

Machinery and Equipment

Manufacturers use 6061 aluminum in machinery and equipment. They create machine frames, molds, and production lines from this alloy. The material allows easy welding and quick machining. This saves time and boosts productivity.

Sports and Outdoor Equipment

Sports equipment makers prefer 6061 aluminum for its low weight and high strength. Hiking poles stay light for the trail. Fishing rods remain sturdy for tough catches. Golf clubs and bike frames use this material to balance durability and performance.

Solar Industry

The solar industry relies on 6061 aluminum for panel frames and brackets. Installers choose this alloy because it stands up to weather and lasts outdoors. Solar power systems use these parts to support panels reliably.

Related product: Aluminum Solar Panel Frame

Electronics

Electronics manufacturers select 6061 aluminum for device cases, frames, and heat sinks. The material helps cool devices and reduces weight. Phones, laptops, and other gadgets use these parts for better thermal management.

6061 aluminum proves effective by making products stronger and lighter. Its versatility brings it to many industries, from factories to sports fields and beyond.

Final Thoughts

6061 aluminum alloy offers strong corrosion resistance, good weldability, easy machinability, and reliable formability. These characteristics make it a standard choice in electronics and machinery production.

Its lightweight and strength allow it to perform well in different environments. Manufacturers use it to improve efficiency without adding extra bulk.

For more information or technical support, contact Hugh Aluminum. Their team can help with questions or project needs.