Aluminum Extrusion Alloy: What is The Best Alloy for Your Project?

Selecting the right aluminum extrusion alloy affects strength, durability, and cost. Each alloy offers specific properties for different applications.

Match your needs to alloy properties. For bicycle frames, 7005 offers a high strength-to-weight ratio. For window frames, 6063 gives a smooth, corrosion-resistant surface.

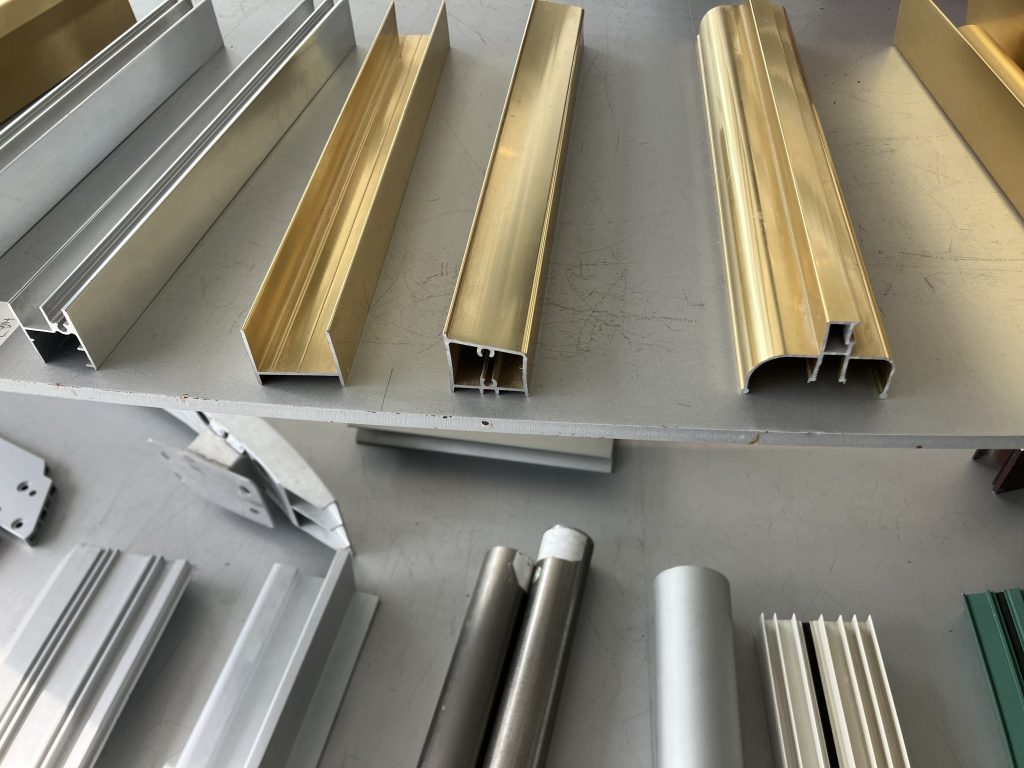

Related products: Extruded aluminum profiles

Common Aluminum Extrusion Alloys

- 6061: High strength, weldable, versatile

- 6063: Excellent finish, good corrosion resistance

- 6005: Good strength, easily formed

- 6082: High strength, good machinability

Aluminum Alloy Properties for Aluminum Extrusion

Aluminum extrusions deliver strength, low weight, and corrosion resistance. These properties make them valuable in the automotive, construction, and electronics industries.

Aluminum Alloy Grades

Manufacturers group aluminum alloys by series numbers. Each series contains specific alloying elements.

- 1xxx Series:

- Contains at least 99% aluminum

- Offers high electrical conductivity and corrosion resistance

- Used for electrical conductors and chemical equipment

- 3xxx Series:

- Contains manganese

- Provides moderate strength and good corrosion resistance

- Used for fuel tanks and piping

- 5xxx Series:

- Contains magnesium

- Delivers moderate to high strength and excellent corrosion resistance

- Used for marine parts and storage tanks

- 6xxx Series:

- Contains magnesium and silicon

- Combining strength, corrosion resistance, and weldability

- Used for architectural profiles and automotive parts

Alloying Elements and Their Effects

Adding magnesium, silicon, or copper changes aluminum’s strength and corrosion resistance. For example, 6061 alloy offers high strength and machinability. 6063 alloy provides a smooth surface for visible parts.

Aluminum Tempering

Tempering increases aluminum’s strength and usability. Each temper code describes a process and result.

- T1: Cooled from high temperature, naturally aged

- T4: Solution heat-treated, naturally aged

- T5: Cooled from high temperature, artificially aged

- T6: Solution heat-treated, artificially aged

Alloy Series Comparison

| Series | Main Element(s) | Strength | Corrosion Resistance | Common Uses |

|---|---|---|---|---|

| 1xxx | None (99%+ aluminum) | Low | Excellent | Electrical, chemical |

| 3xxx | Manganese | Moderate | Good | Fuel tanks, piping |

| 5xxx | Magnesium | Moderate-High | Excellent | Marine, storage tanks |

| 6xxx | Magnesium, Silicon | High | Excellent | Architecture, automotive |

Practical Selection Tips

- Choose 6061-T6 for strong, weldable parts.

- Use 6063-T5 for smooth finishes and complex shapes.

- Select the 5xxx series for marine or corrosive environments.

Selecting the correct alloy and temper ensures that your extrusion meets the requirements for strength, durability, and appearance. Match alloy properties to your project for the best results.

5xxx Series Aluminum Extrusion

The 5xxx series uses magnesium as the main alloying element. Common grades include 5052, 5005, 5083, and 5A05.

Core Properties

- Low Density: 5xxx series alloys are lightweight. For example, 5052 aluminum has a density of 2.68 g/cm³.

- High Strength: 5052 aluminum delivers a yield strength of 193 MPa and an ultimate tensile strength of 228 MPa.

- High Elongation: These alloys can stretch and deform without breaking. This property supports forming and shaping.

- Fatigue Resistance: 5xxx series alloys resist damage from repeated loading. They maintain strength under vibration and cyclical stress.

- Corrosion Resistance: Magnesium forms a stable oxide layer that protects against moisture and chemicals. 5xxx alloys perform well in marine and chemical settings.

- Weldability: These alloys weld easily and keep their strength after welding.

- Machinability: Standard machining tools can shape 5xxx alloys with precision.

Common Uses

- Ship hulls and marine structures

- Storage tanks

- Automotive panels

- Architectural panels

- Fuel tanks and piping

Example

A boat hull made from 5083 aluminum resists saltwater corrosion, stays lightweight, and allows easy welding for repairs.

Summary Table

| Alloy | Magnesium (%) | Yield Strength (MPa) | Corrosion Resistance | Typical Use |

|---|---|---|---|---|

| 5052 | 2.2–2.8 | 193 | Excellent | Marine, automotive, tanks |

| 5083 | 4.0–4.9 | 215–260 | Excellent | Shipbuilding, pressure vessels |

| 5005 | 0.5–1.1 | 110 | Very Good | Architectural panels |

Key Point

5xxx series aluminum alloys combine low weight, high strength, and strong corrosion resistance. They work well in projects exposed to moisture, salt, or frequent stress.

6xxx Series Aluminum Extrusion

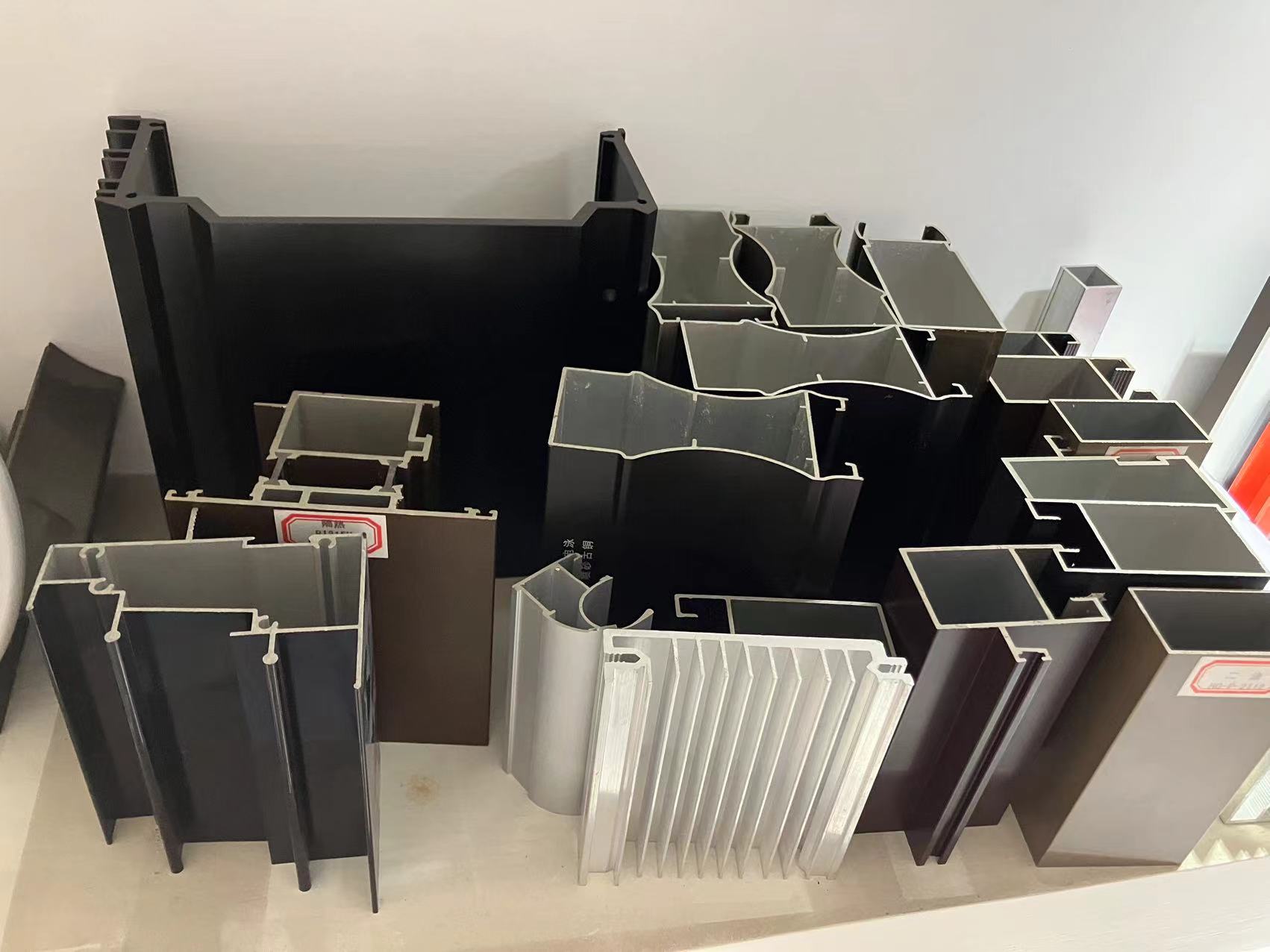

The 6xxx series uses magnesium and silicon as main alloying elements. Common grades include 6005, 6060, 6061, 6063, 6082, 6201, 6262, 6463, and 6A02.

Key Properties

- Strength: 6005 aluminum provides medium to high strength. Its tensile strength is at least 175 MPa. Its yield strength is at least 80 MPa. Elongation reaches 15% or higher. 6061-T6 aluminum offers a yield strength of 276 MPa and a tensile strength of 310 MPa. Elongation is 12%. Brinell hardness is 95.

- Corrosion Resistance: Alloys in this series resist oxidation and chemical exposure. They maintain durability in outdoor and industrial settings.

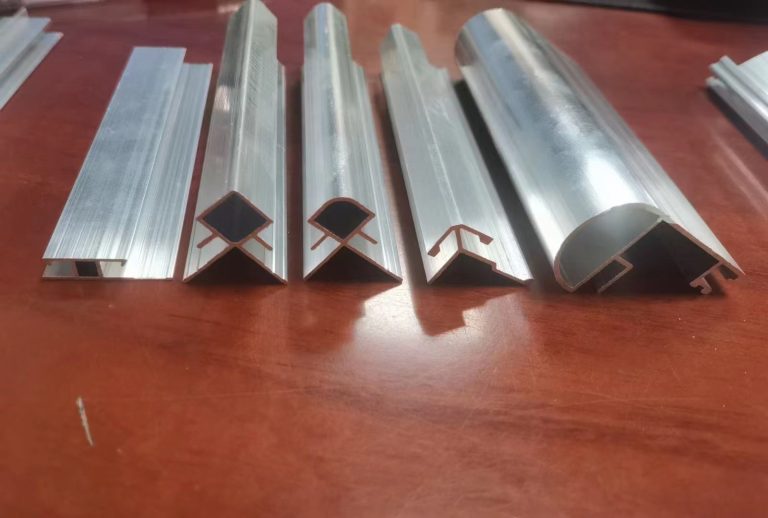

- Weldability and Machinability: 6061 and 6063 weld and machine easily. They support complex shapes and precise profiles.

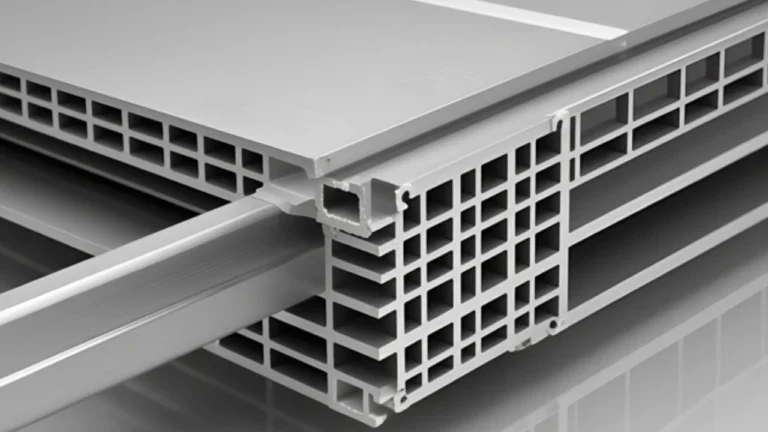

- Thermal Conductivity: 6xxx alloys dissipate heat efficiently. They work well for heat sinks and electronic housings.

Typical Applications

- Automotive frames and chassis

- Window frames and architectural trim

- Ladders and furniture

- Machine parts and heat exchangers

Example

A truck frame made from 6061-T6 aluminum combines strength and low weight. This improves fuel efficiency and load capacity. Window frames made from 6063 alloy offer a smooth finish and resist corrosion in coastal areas.

Selection Tips

- Choose 6005 or 6082 for parts that need higher strength.

- Use 6061 for a balance of strength, weldability, and corrosion resistance.

- Select 6063 for profiles that require a smooth surface and complex shapes.

Summary Table

| Alloy | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Common Uses |

|---|---|---|---|---|

| 6005 | ≥175 | ≥80 | ≥15 | Structural profiles, ladders |

| 6061-T6 | 310 | 276 | 12 | Frames, trucks, towers |

| 6063 | 190–240 | 130–190 | 8–12 | Window frames, trim |

| 6082 | 250–340 | 200–310 | 8–12 | Chassis, bumper beams |

Key Point

6xxx series aluminum alloys combine strength, corrosion resistance, and workability. They support a wide range of extrusion projects in construction, transportation, and manufacturing.

Factors to Consider When Selecting Aluminum Extrusion Alloys

Wall thickness and shape complexity are critical in choosing an aluminum extrusion alloy. Thin walls and detailed profiles require alloys with high formability. For example, 6063 aluminum produces precise, consistent shapes and resists distortion, making it ideal for complex designs.

Strength requirements also drive alloy selection. 6061 aluminum provides high tensile and yield strength, supporting structural applications and heavy loads. For even greater strength, 7000 series alloys are often used in demanding environments such as transportation or industrial machinery.

Corrosion resistance matters for products exposed to moisture or chemicals. 5000 series alloys perform well in marine and outdoor conditions, while 6000 series alloys resist oxidation and suit most architectural needs.

Surface finish can influence your choice. If your project needs a smooth or decorative appearance, 6063 aluminum stands out for its excellent finish and compatibility with anodizing or painting.

Weldability and machinability affect fabrication. Alloys like 6061 and 6063 weld and machine easily, supporting efficient production and precise results.

Cost is always a factor. While higher-grade alloys may cost more initially, they can reduce maintenance and replacement expenses over time, especially in harsh environments.

Match each alloy’s properties to your product’s function and environment. For example, 5083 aluminum works well for marine hardware due to its corrosion resistance, while 6061 is common in automotive frames for its strength and weldability.

Before deciding, ask if the extrusion must support heavy loads, require thin walls, or withstand corrosion. Consider the needed surface finish, fabrication methods, and long-term costs. Clear answers to these questions will guide you to the best aluminum extrusion alloy for your project.

Benefits of Choosing the Right Aluminum Extrusion Grade

Choosing the right aluminum extrusion grade prevents design failures and reduces costs. The correct alloy delivers the strength, corrosion resistance, and finish your project needs.

For example, 6061 works well for structural frames, while 6063 is ideal for smooth, detailed profiles. Relying on expert guidance helps you match alloy properties to your application, ensuring reliable performance and long-term value.

Hugh Aluminum supports clients with over two hundred extrusion products and OEM services. Our team helps you match alloy properties to your specific requirements, ensuring reliable performance and long-term value.

Choosing the right aluminum extrusion grade is a direct way to protect your investment and achieve project success.