6063 Aluminum vs 6061 Aluminum: A Full Comparison Guide

Aluminum alloys shape vehicles, buildings, and consumer products. Two of the most common alloys, 6063 and 6061, each offer clear advantages for specific uses.

6061 aluminum provides high strength and durability. Manufacturers use it in bridges, bicycle frames, and car parts where structural integrity matters. 6063 aluminum delivers a smooth surface and strong corrosion resistance. It works well in window frames, architectural trim, and decorative fixtures exposed to weather.

Choosing between 6063 and 6061 affects product lifespan and performance. For example:

- 6063 is ideal for projects that require a clean finish and easy shaping.

- 6061 is better for parts that must handle heavy loads or repeated stress.

This guide provides a detailed comparison of 6063 and 6061 aluminum. You will find clear data on chemical composition, mechanical properties, fabrication, and real-world applications.

What Are 6063 and 6061 Aluminum Alloys?

6063 aluminum contains magnesium and silicon. Manufacturers use it to create thin-walled, complex shapes with smooth surfaces. This alloy resists corrosion and takes anodized finishes well. Common uses include window frames, door frames, and decorative trim. 6063 performs well outdoors due to its strong moisture resistance.

6061 aluminum is an alloy that combines magnesium, silicon, copper, and chromium. It delivers a high strength-to-weight ratio and resists cracking under heavy loads. Engineers choose 6061 for bridges, towers, and heavy-duty frameworks. This alloy responds well to heat treatment, which increases its strength for both sheet and extruded parts.

Choose 6063 for projects that need a clean finish and corrosion resistance. Select 6061 for applications that demand strength and durability.

Chemical Composition: 6063 vs 6061

The differences in alloying elements between 6063 and 6061 drive their unique properties and applications.

| Element | 6063 (%) | 6061 (%) |

|---|---|---|

| Magnesium | 0.45 – 0.90 | 0.8 – 1.2 |

| Silicon | 0.20 – 0.60 | 0.4 – 0.8 |

| Iron | 0 – 0.35 | 0 – 0.7 |

| Copper | 0 – 0.10 | 0.15 – 0.4 |

| Chromium | 0 – 0.10 | 0.04 – 0.35 |

| Manganese | 0 – 0.10 | 0 – 0.15 |

| Zinc | 0 – 0.10 | 0 – 0.25 |

| Titanium | 0 – 0.10 | 0 – 0.15 |

| Aluminum | 97.5 – 99.35 | 95.8 – 98.6 |

6061 contains higher magnesium and copper, contributing to greater strength, while 6063’s purer composition and lower alloying element content favor extrudability and surface quality.

Mechanical and Physical Properties Comparison

| Property | 6061-T6 | 6063-T6 |

|---|---|---|

| Tensile Strength | 310 MPa (45,000 psi) | 190 MPa (28,000 psi) |

| Yield Strength | 276 MPa (40,000 psi) | 160 MPa (23,000 psi) |

| Brinell Hardness | 95 | 73 |

| Density | 2.70 g/cm³ | 2.70 g/cm³ |

| Modulus of Elasticity | 68.9 GPa | 68.9 GPa |

| Shear Strength | 30,000 psi | 22,000 psi |

6061 outperforms 6063 in strength and hardness, making it suitable for structural components. 6063, while softer, is preferred for applications demanding intricate shapes and superior surface finish.

Corrosion Resistance and Surface Finish

6063 aluminum resists corrosion in outdoor and humid conditions. Its magnesium and silicon content help form a protective oxide layer. Manufacturers often use 6063 for window frames, door frames, and exterior trim because it keeps its appearance over time.

Anodizing 6063 produces a smooth, even finish. The oxide layer created by anodizing can be colored and does not peel or chip. This makes 6063 suitable for visible architectural parts that need both durability and a clean look.

6061 aluminum also resists corrosion but contains a small amount of copper. This copper can make 6061 more likely to corrode in harsh environments. Anodizing 6061 increases its resistance, especially when combined with proper sealing.

Key points:

- 6063 offers strong corrosion resistance and a smooth anodized finish.

- 6061 performs well after anodizing and sealing, but is less resistant than 6063 in aggressive conditions.

- Use 6063 for parts exposed to weather and where surface quality matters. Choose 6061 for structural parts that still need corrosion protection.

Workability, Weldability, and Machinability

Welders use 6061 for frames and supports. It forms strong, clean joints.

Manufacturers produce thin-walled, complex shapes for windows and decorative profiles with 6063.

Key points:

- 6061 is best for parts that need precision machining and strong welds.

- 6063 is ideal for forming, bending, and creating detailed extrusions.

- Both alloys respond well to welding, but 6063 regains strength more easily after heat treatment.

Choose 6061 for tight tolerances and strength.

Choose 6063 for complex shapes and easy forming.

Applications: Where Is Each Alloy Used?

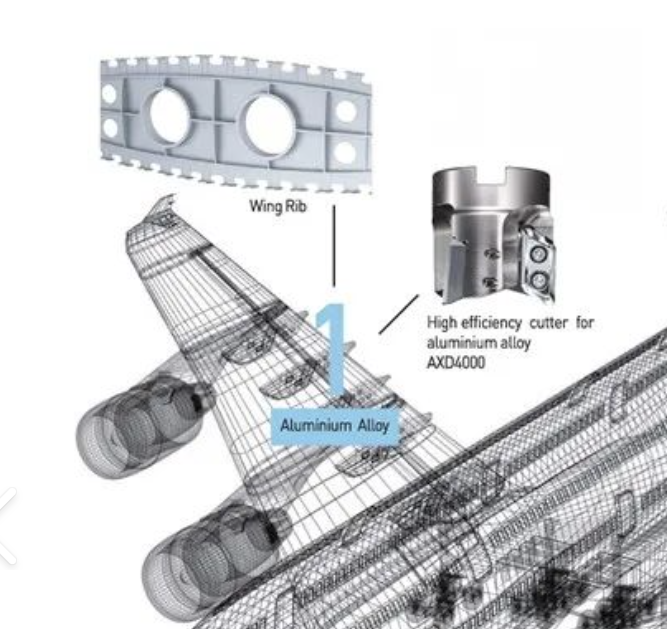

6061 aluminum supports heavy loads and resists impact. Engineers use it in bridges, towers, and structural frameworks. Aerospace and automotive industries select 6061 for aircraft fittings, car chassis, and truck beds.

Marine hardware, such as boat parts and dock components, relies on 6061 for strength and corrosion resistance. Manufacturers also use 6061 for industrial ramps and bicycle frames that require durability.

6063 aluminum creates smooth, detailed shapes. Builders choose 6063 for window frames, door frames, and curtain walls. Designers use it for decorative trim, railings, and moldings that must look clean and resist weather. HVAC and irrigation systems use 6063 for piping and tubing.

Furniture makers select 6063 for shelving and modular office systems. Recreational equipment, including sports gear and lightweight bike frames, often uses 6063 for its finish and formability.

Cost and Availability

Both 6061 and 6063 aluminum alloys are widely available in standard bars, tubes, and extrusions. Suppliers commonly stock 6063 for architectural profiles like window and door frames due to its popularity in construction. 6063 usually costs less than 6061 because of its simpler composition and easier extrusion.

6061 aluminum costs more because it offers higher strength and versatility. Prices for 6061 range from $2.50 to $3.50 per pound for basic forms like sheets and plates. Complex or thick extrusions cost more. 6061 comes in various shapes and sizes, including sheets, plates, bars, and specialized extrusions, making it suitable for structural and industrial projects.

Prices for both alloys fluctuate with market demand, raw material costs, and supply chain factors. Buyers ordering large quantities or custom profiles should compare suppliers and seek bulk discounts. For architectural and decorative uses, 6063 offers a cost advantage. For strength-critical applications, 6061 justifies its higher price with better performance.

How to Choose: 6063 or 6061 for Your Project?

Choose the aluminum alloy based on your project needs: strength, appearance, corrosion resistance, fabrication, or budget.

Use 6061 for heavy loads and repeated stress. It suits bridges, towers, and structural frames. For example, loading ramps and bicycle frames benefit from 6061’s durability.

Pick 6063 for a smooth finish and good anodizing. It fits window frames, decorative trim, and architectural details. 6063 works well for projects where looks matter, like storefronts or railings.

6063 resists corrosion better in harsh or visible environments, especially after anodizing. It keeps its look longer outdoors.

6063 extrudes easily into complex shapes and thin profiles. It suits large runs of custom designs, such as moldings or tubing. 6061 machines and welds well, fitting heavy-duty parts needing tight tolerances and strong joints.

6063 usually costs less for non-structural, high-volume extrusions. Choose it to save money if strength is not critical.

Ask yourself:

- Does the part need to bear weight or resist impact? Choose 6061.

- Is a smooth, attractive finish essential? Choose 6063.

- Will the part face harsh weather or corrosive conditions? Choose 6063.

- Do you need complex shapes or easy extrusion? Choose 6063.

- Are you on a tight budget for decorative or architectural work? Choose 6063.

Match the alloy to your needs to avoid costly mistakes.

Frequently Asked Questions (FAQ)

Is 6061 stronger than 6063?

Yes, 6061 offers higher tensile and yield strength, making it better for structural applications.

Can you weld 6063 to 6061?

Yes, both alloys are weldable, though their post-weld properties may differ. Post-weld heat treatment can help restore strength.

Which alloy is better for outdoor use?

Both perform well outdoors; 6063 is preferred for visible architectural applications due to its superior anodizing and corrosion resistance.

What are the main differences in anodizing results?

6063 produces a more uniform and attractive anodized finish, making it ideal for decorative purposes.

Are there alternatives to 6061 and 6063?

Yes, other 6xxx series alloys like 6082 may be considered for specific strength or extrudability requirements.

Conclusion

6061 and 6063 aluminum alloys each offer unique strengths. Choose 6061 for structural strength and versatility, and 6063 for superior surface finish and corrosion resistance in architectural applications. Understanding the specific needs of your project will ensure you select the optimal alloy for performance, durability, and cost-effectiveness.