Why Structural Aluminum is the Best Choice for Window Walls and Curtain Walls: A Full Guide

Structural aluminum supports glass panels in window walls and curtain walls. This material is light, strong, and resists rust. Builders use aluminum to create slim frames that hold large sections of glass. These frames allow more natural light into buildings.

Aluminum is easy to shape. Manufacturers can make frames in many sizes and forms. This flexibility helps architects design modern buildings with clean lines. Aluminum frames also speed up the installation process, saving time on-site.

Property owners benefit from aluminum’s long lifespan. The material needs little maintenance. It does not corrode easily, so it stays in good shape for many years. This reduces repair costs and keeps buildings looking new.

This guide explains why aluminum is a smart choice for window walls and curtain walls. It compares aluminum to other materials. It shares real examples from buildings and gives clear advice for choosing the right system. If you want a building that looks great and lasts, aluminum is a reliable option.

What Are Window Walls and Curtain Walls?

Window walls use glass and aluminum panels installed between floors. These panels do not carry the building’s weight. They let in daylight and provide clear views. You often find window walls in homes and offices.

Curtain walls attach to the outside of a building. They cover the building from top to bottom. Curtain walls protect against wind, rain, and earthquakes. They also give the building a smooth, modern look.

Key Differences

- Window walls fit between floor slabs. Curtain walls hang on the outside of the slabs.

- Window walls may have covers that hide the edges of the floors. Curtain walls create a continuous glass surface.

- Curtain walls appear more often in tall and commercial buildings. They can span several floors and support bold designs.

The window walls go between floors, and curtain walls cover the building’s exterior. Both use glass and aluminum to bring in light, but their installation and appearance differ.

What Is Structural Aluminum?

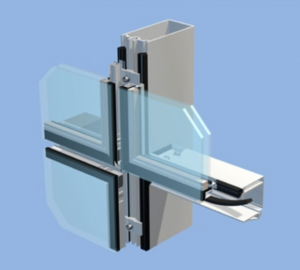

Structural aluminum is a strong material used to support window and curtain wall systems. Manufacturers shape aluminum by pushing it through a mold. This process is called extrusion.

Aluminum became common in construction after the 1920s. The Hall-Héroult process made aluminum more affordable. Builders used it in projects like the Empire State Building.

Aluminum is light but can hold heavy loads. This lets builders use thin frames for wide glass panels. Aluminum does not rust. It stands up to rain, sun, cold, and heat. Manufacturers can make aluminum in many shapes to fit different building designs.

The structural aluminum creates frames that are strong, light, and long-lasting. Builders and architects choose it for its reliability and flexibility.

Why Choose Aluminum Over Other Materials?

| Material | Weight | Durability | Maintenance | Sustainability | Flexibility | Cost (Lifecycle) |

| Aluminum | Light | High | Low | Excellent | High | Lower |

| Steel | Heavy | High | Moderate | Good | Moderate | Higher |

| Wood | Medium | Moderate | High | Variable | Moderate | Higher |

| PVC | Light | Low | Moderate | Poor | Low | Low |

Aluminum Advantages:

- Superior corrosion resistance compared to steel, especially in harsh environments.

- Lower maintenance costs and longer lifespan.

- High recyclability and lower embodied energy than steel or PVC.

- Greater design freedom for complex, modern facades.

Key Benefits of Structural Aluminum for Window and Curtain Walls

Strength and Durability

Structural aluminum supports large glass panels with a minimal frame. The material has a high strength-to-weight ratio. Aluminum resists wind, earthquakes, and temperature changes. It does not rust. Buildings near the sea or in cities benefit from its long life.

Design Flexibility

Manufacturers shape aluminum into many forms. This allows for custom profiles and different frame sizes. Architects use aluminum to create slim frames and wide glass areas. Prefabricated parts make installation fast and accurate.

Energy Efficiency and Sustainability

Aluminum frames use thermal breaks and insulated profiles. These features reduce heat loss and improve energy use. Double or triple glazing, Low-E coatings, and tight seals increase savings. Aluminum is fully recyclable. Builders use it to meet green building standards.

Ease of Installation and Maintenance

Prefabricated systems make installation quick. Workers spend less time on site. Aluminum needs little maintenance. Cleaning and simple checks keep it in good shape. If a part breaks, repairs are easy. The material lasts for decades.

Applications and Case Studies

High-Rise Buildings

The Burj Khalifa uses over 26,000 aluminum and glass panels. These panels help the building resist strong winds and temperature changes. Aluminum keeps the structure light and strong. The building’s reflective surface stands out in the city.

Commercial Complexes

Landmarks like the Sydney Opera House and the Eden Project use aluminum frames. These frames allow for flexible shapes and long service life. The large glass sections let in daylight and help control energy use.

Residential Towers

Aluminum profiles make wide glass spans possible in apartment towers. These spans give residents open views and natural light. Homes with these features often have higher property value.

Aluminum supports buildings of many types. It handles weather, keeps structures looking modern, and improves comfort for people inside.

How to Specify and Source Structural Aluminum Systems?

Selection Criteria

- Check system performance for thermal insulation, structural strength, and sound control.

- Confirm the system meets local building codes and fire safety standards.

- Choose suppliers with a strong reputation, valid certifications, and clear warranties.

Leading Manufacturers

- Select companies known for reliable products and consistent quality.

- Prefer manufacturers who provide support after installation.

Specification Tips

- Request technical data and test reports to verify system claims.

- Use modular or unitized systems for high-rise or complex projects to speed up installation.

- Choose suppliers who offer recyclable products to support green building goals.

Clear choices and careful checks help you find the right aluminum system. Good suppliers and accurate data make projects run smoothly and keep buildings safe.

Frequently Asked Questions (FAQs)

With proper maintenance, aluminum systems can last 40-60 years or more, thanks to their corrosion resistance and durability.

Yes. Modern systems use advanced thermal breaks, double/triple glazing, and Low-E coatings to achieve excellent energy performance.

Routine cleaning every 3-6 months, inspections for sealant and gasket integrity, and prompt repair of any damage.

Aluminum is highly recyclable and often contains a high percentage of post-consumer recycled content, supporting green building goals.

Final Thoughts

Structural aluminum gives window walls and curtain walls clear benefits. The material provides strength and a long lifespan. It allows for flexible design and supports energy savings.

Architects, builders, and owners often choose aluminum for reliable and modern building envelopes. The choice makes construction easier and results more predictable.

Work with experienced suppliers. Make sure your system meets all codes and standards. With these steps, your building will stay strong, look good, and last for many years.