What are the Materials of Aluminum Photovoltaic Frames? A Complete Guide

Aluminum photovoltaic frames are a key part of solar panels. They provide support for the solar cells and protect them from damage caused by weather or handling. This article explains the materials used to make these frames, why they are chosen, and their benefits and drawbacks. It also looks at how these materials impact the environment.

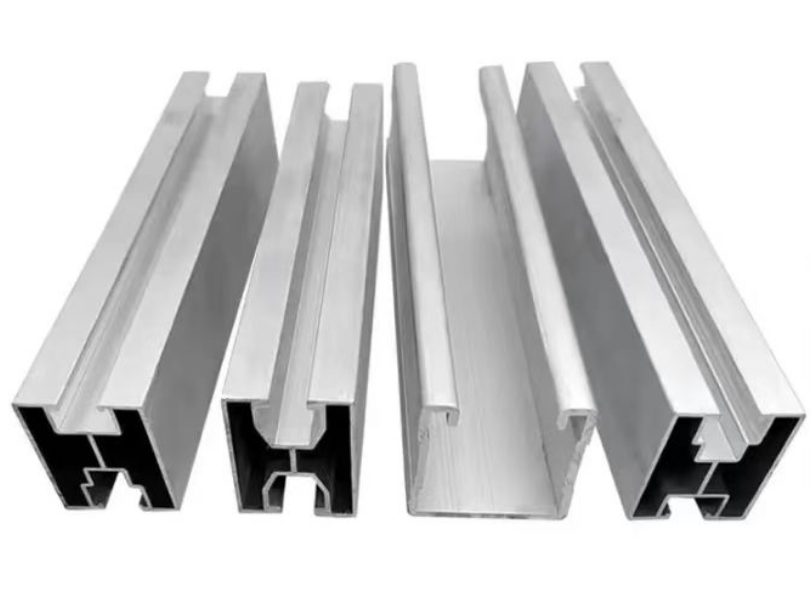

What Are Aluminum Photovoltaic Frames?

Aluminum photovoltaic frames are structural components that encase solar panels to protect them from environmental damage. They shield panels from wind, rain, and debris while ensuring they remain securely mounted on rooftops, ground installations, or other surfaces. These frames provide the stability required for solar panels to operate efficiently over time.

Why is aluminum preferred?

Aluminum is the leading choice for photovoltaic frames due to its unique combination of practical benefits:

- Lightweight: Aluminum is easy to transport and install without compromising strength.

- Corrosion Resistance: It withstands exposure to moisture and harsh weather, making it ideal for outdoor use.

- High Strength-to-Weight Ratio: Aluminum provides durability and stability while remaining manageable for large-scale applications.

- Recyclability: Fully recyclable, aluminum supports sustainability goals in the renewable energy sector.

These qualities make aluminum an efficient, durable, and environmentally friendly material for solar panel frames.

Types of Aluminum Alloys Used in Photovoltaic Frames

Aluminum alloys used in photovoltaic frames are selected for their strength, durability, and resistance to environmental factors. Below are the most commonly used alloys and their key characteristics.

6063-T5 Alloy

The 6063-T5 alloy is widely used for standard solar panel frames. It offers a smooth surface finish and excellent corrosion resistance. These qualities make it ideal for outdoor use, where panels are exposed to moisture and changing weather conditions. Its lightweight nature also simplifies handling and installation.

6061-T6 Alloy

The 6061-T6 alloy is known for its high strength and weldability. It performs well in harsh environments, such as areas with extreme temperatures or heavy mechanical loads. This alloy is often chosen for projects that require durable frames capable of withstanding significant stress over time.

6082-T6 Alloy

The 6082-T6 alloy provides strong bending resistance, making it suitable for industrial and transportation applications. It is often used in large solar installations where structural stability is critical. For example, it works well in solar farms or systems installed on moving platforms like trains or ships.

6005-T6 Alloy

The 6005-T6 alloy delivers excellent mechanical performance and is ideal for rooftop installations that require curved or custom brackets. Its combination of strength and flexibility allows it to support unique designs while maintaining stability. This alloy is a preferred choice for modern solar panel systems integrated into architectural designs.

Each alloy serves a specific purpose, ensuring that photovoltaic frames meet the demands of their installation environment. Choosing the right material enhances the durability and efficiency of solar systems, contributing to their long-term performance and reliability.

Surface Treatments for Aluminum Frames

Surface treatments improve the durability and appearance of aluminum photovoltaic frames. They protect the material from environmental damage and allow for customization in color and finish. Below are three common methods used to treat aluminum frames:

Anodizing

Anodizing forms a protective oxide layer on the aluminum surface. This layer increases corrosion resistance, making the frame suitable for harsh environments like coastal areas. The process also gives the aluminum a smooth, metallic finish that enhances its visual appeal.

Electrophoresis

Electrophoresis applies a protective coating using an electrochemical process. This coating strengthens the frame against scratches and weather exposure. It also allows for color customization, making it ideal for projects that require specific aesthetic designs. For example, black electrophoretic coatings are often chosen for their modern look.

Powder Coating

Powder coating involves applying a dry powder to the aluminum surface and curing it with heat. This creates a durable, even finish available in various colors and textures. Powder-coated frames are visually striking but may be prone to minor scratches over time. Regular cleaning can help maintain their appearance.

These surface treatments offer practical solutions for protecting aluminum frames while adding style and functionality. Choosing the right method depends on your project’s environment, durability needs, and design preferences.

Comparison of Aluminum vs Steel Solar Panel Frames

| Feature | Aluminum Frames | Steel Frames |

|---|---|---|

| Weight | Lightweight for easy handling | Heavy and difficult to transport |

| Cost | Higher upfront cost but durable | Lower initial cost but requires maintenance |

| Durability | Excellent corrosion resistance | Susceptible to rust in humid conditions |

| Environmental Impact | Highly recyclable | Energy-intensive recycling process |

| Appearance | Sleek and modern finish | Industrial look |

Advantages of Aluminum Photovoltaic Frames

Aluminum photovoltaic frames provide several clear and practical benefits, making them a reliable choice for solar panel systems:

- Lightweight and Easy to Handle: Aluminum is light, which simplifies transportation and installation. This reduces effort, time, and costs, especially for large-scale solar projects.

- Strong and Durable: Despite being lightweight, aluminum is strong enough to handle heavy loads like wind pressure and snow. It ensures the stability and safety of solar panels in various weather conditions.

- Corrosion Resistance: Aluminum naturally resists rust and corrosion. This makes it ideal for outdoor use, even in humid or coastal areas, where other materials might degrade over time.

- Environmentally Friendly: Aluminum is fully recyclable without losing its quality. Using aluminum frames supports sustainability by reducing waste and conserving resources.

- Customizable for Different Needs: Aluminum can be shaped into various designs and sizes. This flexibility allows it to meet the specific requirements of residential, commercial, or industrial solar installations.

Aluminum frames combine practicality, durability, and sustainability. Their features make them a dependable option for long-lasting solar energy systems in any environment.

Challenges and Limitations

Aluminum photovoltaic frames, while advantageous, have specific drawbacks that should be carefully evaluated:

Higher Upfront Costs

Aluminum frames are more expensive than steel options. This can increase the initial investment for solar projects, particularly large installations. However, their durability and recyclability may reduce costs over the system’s lifetime.

Prone to Surface Damage

Aluminum can scratch or dent easily if left untreated. Protective coatings or anodizing can prevent damage and preserve the frame’s appearance and functionality.

Thermal Expansion Risks

Aluminum expands and contracts with temperature changes. In areas with extreme temperature swings, this can cause structural stress or alignment issues. Engineers often address this by designing frames to accommodate thermal movement.

By understanding these limitations, manufacturers and installers can implement solutions to maximize the performance and longevity of aluminum frames in solar systems.

Frequently Asked Questions (FAQ)

Why are aluminum frames primarily silver or black?

Silver anodized or black powder-coated finishes provide uniformity and aesthetic appeal while protecting against corrosion.

What is the lifespan of aluminum photovoltaic frames?

With proper surface treatment, aluminum frames can last over 25 years.

Can aluminum frames withstand extreme weather conditions?

Yes, they are designed to resist corrosion from rain, snow, UV rays, and other environmental factors.

Final Thoughts

Aluminum photovoltaic frames play a crucial role in solar panel construction. They are strong, lightweight, and environmentally friendly. Understanding their materials, coatings, benefits, and challenges helps consumers choose reliable and efficient solar energy systems. A well-built frame ensures that panels last longer and perform effectively, even in tough conditions.