Aluminium in Building and Construction Industry: Properties, Uses, and Outlook for 2025

Aluminium is now a primary material in construction due to its strength, light weight, and sustainability. Builders choose aluminium for structures that require durability without added bulk.

In 2025, the demand for aluminium continues to rise. New technologies, stricter environmental standards, and the global shift toward sustainable building drive this growth. For example, the global aluminium market is projected to reach $281.8 billion by 2030, with construction making up a significant portion.

Aluminium offers clear advantages:

- It resists corrosion, reducing maintenance costs.

- It is fully recyclable, thereby reducing its environmental impact.

- It can be shaped into precise profiles for windows, facades, and solar frames.

Recycled aluminium uses up to 95% less energy than new production. This efficiency appeals to developers aiming for green certifications and lower operating costs.

Challenges remain. Aluminium prices can fluctuate, and manufacturers must adapt to changing regulations. However, these pressures encourage innovation, such as the development of zero-emission production methods.

For architects, builders, and investors, aluminium offers a reliable solution for sustainable, efficient, and modern construction projects. Its proven performance and adaptability make it a strong choice for the future of building.

Related products: Architectural aluminum extrusions for construction and building

Properties of Aluminium That Make It Ideal for Construction

High Strength-to-Weight Ratio

Aluminium supports heavy loads without adding extra weight. Builders use aluminium beams in high-rise buildings and bridges to reduce structural mass. Lighter materials lower transportation and installation costs.

Corrosion Resistance

Aluminium forms a protective oxide layer when exposed to air. This layer prevents rust and weather damage. Buildings near the ocean benefit from aluminium’s durability, reducing repair needs over time.

Complete Recyclability

Aluminium is 100% recyclable. Recycling uses up to 95% less energy than producing new metal. Most construction-grade aluminium includes recycled content, which helps lower project costs and supports sustainability goals.

Thermal and Acoustic Performance

Manufacturers add thermal breaks to aluminium frames to limit heat transfer. This feature improves energy efficiency in buildings. Aluminium window and door systems can also reduce outside noise, creating quieter indoor spaces.

Aluminium’s light weight, corrosion resistance, recyclability, and performance make it a smart choice for modern construction. Builders, architects, and property owners benefit from its reliability and efficiency.

Key Applications of Aluminium in Construction

Residential Buildings

Builders use aluminium for window frames, sliding doors, roofing, and cladding. Slim aluminium profiles allow for larger glass panels, increasing daylight in homes. Aluminium resists rust and needs little maintenance. Many apartment complexes feature aluminium balconies and window systems that last for decades.

Commercial and Industrial Projects

Office towers and shopping centers use aluminium for curtain walls and facade systems. Aluminium allows architects to design large glass surfaces and bold shapes. Its lightweight speeds up installation and reduces labor costs. Factories and warehouses use aluminium modular systems for quick expansion and easy reconfiguration.

High-Rise and Skyscraper Construction

Tall buildings benefit from aluminium’s low weight. Using aluminium reduces the load on foundations and supports taller structures. Developers choose aluminium for complex exteriors, such as curved or angled facades. Aluminium also performs well in earthquake-prone areas due to its lighter mass.

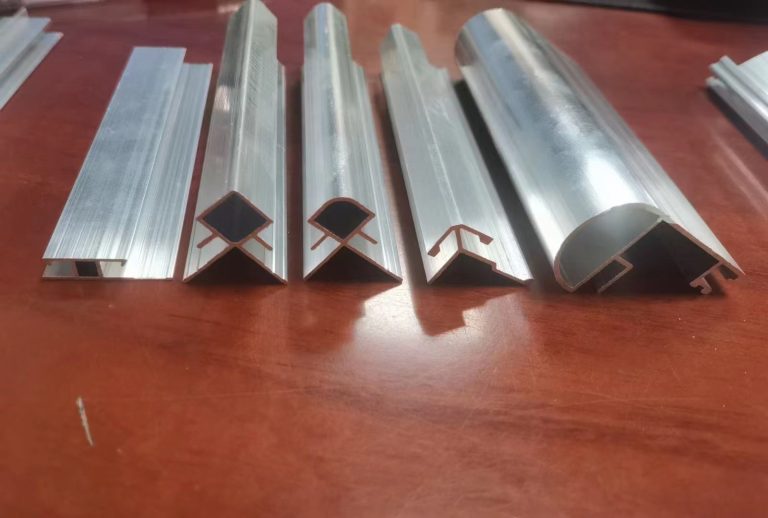

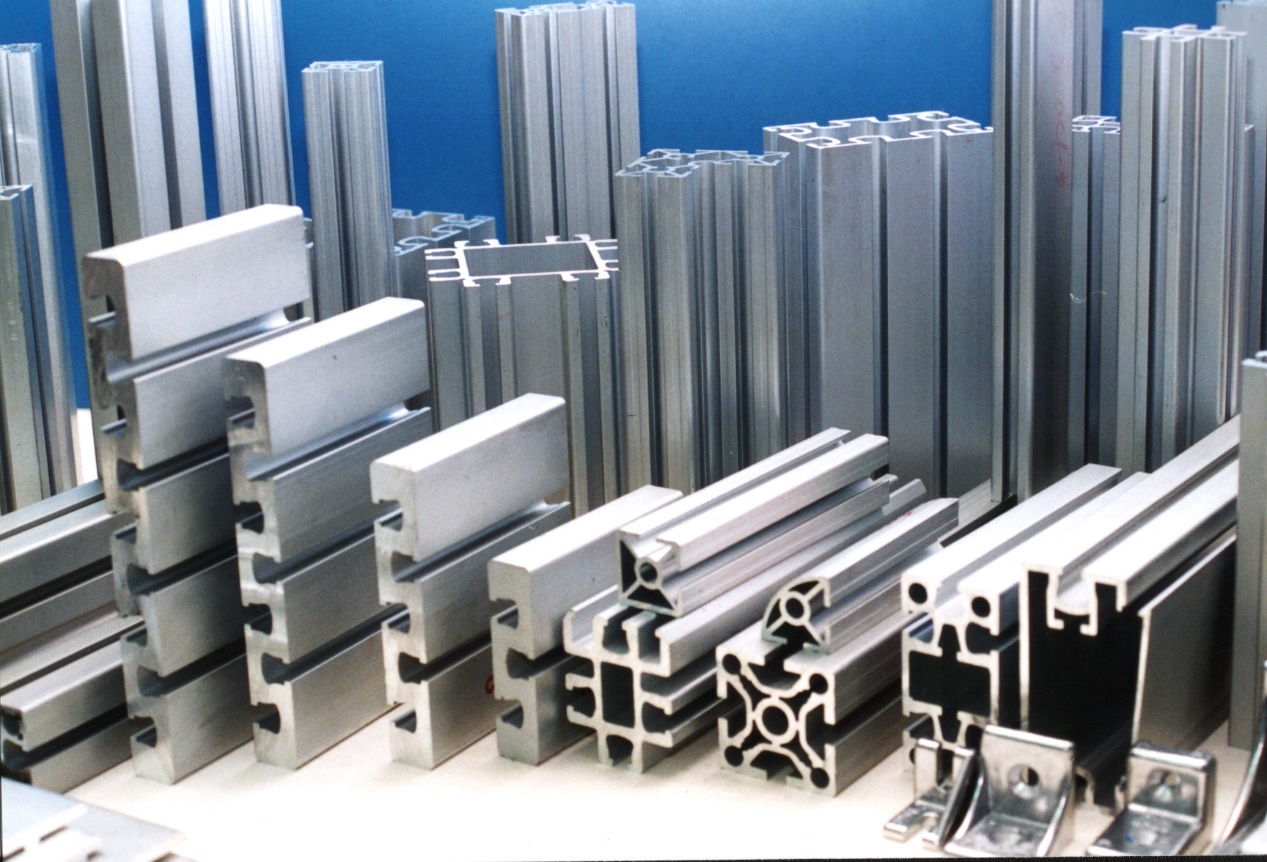

Aluminium Profiles, Panels, and Facades

Manufacturers produce extruded aluminium profiles for framing, support beams, and decorative panels. These components fit together precisely and speed up assembly. Aluminium panels help regulate building temperature in ventilated facade systems, improving energy efficiency.

Roofing, Windows, and Doors

Aluminium stands up to harsh weather, making it ideal for roofing. Its malleability allows for custom roof shapes and seamless gutters. Aluminium windows and doors provide strong insulation and security. These products require little maintenance and keep their appearance for years.

Aluminium’s strength, low weight, and corrosion resistance make it a practical choice for modern construction. Builders and property owners benefit from its reliability and efficiency.

Market Trends and Industry Outlook for 2025

Market Size and Growth

The global aluminium market is projected to reach $190.98 billion in 2025. By 2034, experts expect this figure to grow to $329.08 billion. In construction, the aluminium market should hit $22.81 billion in 2025 and rise to $34.66 billion by 2033. These numbers reflect a steady annual growth rate above 5%.

Growth Drivers

- Sustainability: Developers choose aluminium for its recyclability and low environmental impact. Recycled aluminium uses up to 95% less energy than primary production.

- Urbanization: Cities are expanding, and new buildings require lightweight, durable materials. Aluminium supports fast construction and modern design.

- Technology: New aluminium alloys and advanced manufacturing methods improve product strength and versatility. These innovations open new markets and applications.

Regional Insights

- North America: Demand grows with investments in green infrastructure and electric vehicles. Aluminium supports energy-efficient building projects.

- Europe: Strict regulations push builders to use recycled aluminium and adopt circular economy practices.

- Asia-Pacific: Rapid urban growth in China and India drives large-scale use of aluminium in public works and housing.

Industry Challenges

- High Energy Costs: Producing new aluminium requires large amounts of electricity, raising costs for manufacturers.

- Regulations: New environmental laws force companies to upgrade technology and reduce emissions.

- Supply Chain Risks: Political tensions and raw material shortages can disrupt production and increase prices.

Aluminium demand in construction will continue to rise through 2025. Growth depends on sustainability, urban development, and innovation. Industry challenges remain, but aluminium’s advantages keep it at the center of modern building projects.

Innovations and Future Developments

Stronger Aluminium Alloys

Engineers have created new aluminium alloys with higher strength, better flexibility, and increased corrosion resistance. These alloys support taller buildings and longer bridges. Manufacturers now produce thinner, detailed panels that withstand harsh weather.

Energy-Efficient Building Solutions

Builders use aluminium frames for solar panels on rooftops and parking structures. Insulated aluminium facades help buildings keep stable indoor temperatures, reducing heating and cooling costs. Lightweight aluminium supports green roofs by holding soil and plants above living spaces.

Digital Design and Smart Construction

Architects use 3D modeling software to design precise aluminium parts for prefabricated walls and modular units. Factories produce these parts off-site, which reduces waste and speeds up installation. Smart sensors in aluminium frames monitor building performance and alert owners to maintenance needs.

Advances in aluminium alloys, energy-saving systems, and digital construction tools help builders create efficient, durable, and sustainable structures for the future.

Aluminium vs. Other Construction Materials

| Feature | Aluminium | Steel | uPVC |

|---|---|---|---|

| Weight | Lightweight | Heavy | Lightweight |

| Corrosion Resistance | Excellent | Variable | Excellent |

| Recyclability | 100% | High | Limited |

| Strength | High (relative) | Very High | Moderate |

| Cost | Moderate | Variable | Low |

| Lifespan | Long | Long | Moderate |

Aluminium stands out for its combination of lightness, durability, and recyclability, making it a preferred choice over steel and uPVC in many modern construction applications.

Challenges and Considerations

Supply Chain and Price Volatility

Aluminium prices rise and fall with energy costs and raw material supply. High electricity prices have forced some smelters to close. Shipping delays and route disruptions increase delivery times and costs. These changes make project budgeting and scheduling difficult.

Regulatory and Environmental Pressures

Governments set strict emissions and recycling targets for aluminium producers. Companies must invest in cleaner technology and use more recycled aluminium to meet regulations. For example, the industry now recycles about 76% of scrap, but demand for recycled material keeps rising.

Competition for Scrap Aluminium

Manufacturers compete for scrap aluminium because recycled metal uses 95% less energy than new production. Demand for scrap is strong in Europe, North America, and Asia. Producers improve sorting and recovery to secure enough supply.

Cost Perceptions

Some buyers believe aluminium costs too much. However, aluminium products last longer and need less maintenance than many alternatives. For example, aluminium window frames often outlast wood or steel and reduce long-term repair costs.

Aluminium’s future in construction depends on how well the industry manages energy use, supply risks, and new regulations. Companies that focus on recycling and efficiency will have an advantage in the years ahead.

Practical Guidance for Builders and Architects

Selecting Aluminium Products

- Choose alloys like 6061 or 7075 for structural strength.

- Use 6063 for window and door frames due to its smooth finish.

- Select 5052 or 5083 in coastal or industrial areas for better corrosion resistance.

- Pick systems with thermal breaks and insulation for energy efficiency and sound control.

- Apply powder coating or anodizing for durable, attractive finishes.

Design Best Practices

- Use aluminium for curtain walls and facades to reduce weight and improve energy performance.

- Integrate automated shading or ventilation for better comfort and lower energy use.

- Select modular aluminium systems for fast installation and easy upgrades.

- Specify recycled aluminium to meet green building standards like LEED or BREEAM.

Maintenance and Longevity

- Clean aluminium surfaces with mild soap and water to prevent stains.

- Inspect joints and seals on windows and facades for wear.

- Use advanced coatings or anodizing to protect exposed aluminium, especially outdoors.

- Well-maintained aluminium frames and panels can last for decades and reduce replacement costs.

Aluminium offers strength, flexibility, and low maintenance for modern construction. Builders and architects who follow these guidelines can deliver efficient, long-lasting, and sustainable projects.

Conclusion

Aluminium’s role in building and construction is set to expand further in 2025 and beyond. Its unique properties, coupled with ongoing innovation and a strong sustainability profile, position it as a material of the future for architects, builders, and developers worldwide.

Frequently Asked Questions

Is aluminium eco-friendly for construction?

Yes, aluminium is highly recyclable and supports green building initiatives by reducing energy use and waste.

What are the main disadvantages of aluminium in building?

The primary challenges are energy-intensive production and price volatility, but recycling and technological advances are mitigating these issues.

How does aluminium compare to steel in construction?

Aluminium is lighter, more corrosion-resistant, and easier to recycle, while steel offers higher strength but is heavier and more prone to rust.

What are the best uses of aluminium in modern architecture?

Aluminium excels in facades, windows, doors, roofing, and as structural profiles in both residential and commercial buildings.

By adopting aluminium, the construction industry is building not just for today, but for a sustainable, resilient, and innovative future.