Introduction to the production process of aluminum railing

Aluminum railings being one of the most common metal railings, many people want to understand how it is assembled and manufactured. The process is complex and tedious, but you can scroll down to this blog that discusses the entire process in detail.

The production process of aluminum railing mainly includes the following steps:

1. Design the right aluminum railing:

Designers draw drawings of aluminum railings that meet functional and aesthetic requirements according to customer needs and site environment. These drawings not only contain appearance modeling, but also involve details such as material selection, structural design and process requirements.

The drawings of aluminum railings should contain these parameters:

- Size of balustrade

- Aluminum alloy material used for the railing

- Size of glass (if required)

- Dimensions of fittings to be installed and installation tutorial

- Production considerations

2. Aluminum material purchasing:

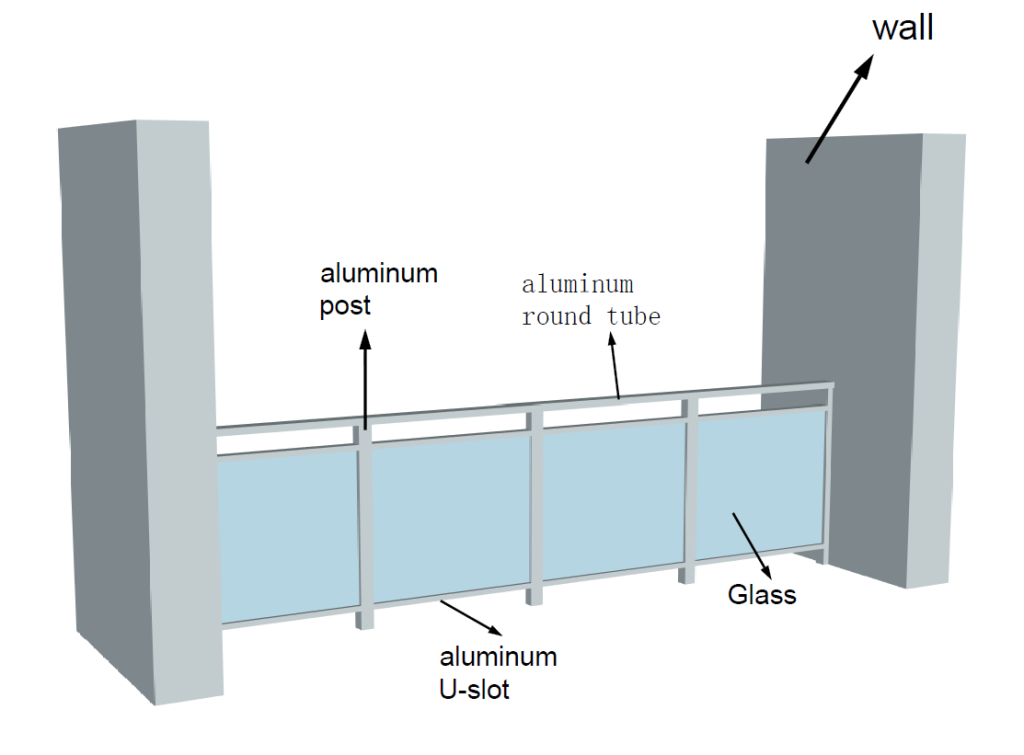

Selection of quality aluminum alloy material is usually procured in the form of aluminum profiles (aluminum square tubes, oval tubes and U-channels). Aluminum profiles of different types of alloys vary in tensile strength, bending strength, hardness and corrosion resistance.

This table below lists the characteristics of commonly used aluminum alloys:

| aluminum alloy grade | tensile strength (MPa) | bending strength (MPa) | hardness | corrosion resistance |

|---|---|---|---|---|

| 6061 | 124 – 180+ | 228 | HB90-95(6061-T6)

HB70-150(aluminum alloy 6061) |

good,But poor resistance to seawater |

| 6063 | 117 – 207 | 195 | HB60-95 | excellent |

It is important to note that the quality of the material should be tested before purchasing aluminum. For example, test the hardness and strength, so that you can avoid purchasing poor quality materials.

3. Cutting aluminum tubes or processing railing frame:

According to the design drawings, cut the aluminum tube into the required length and shape. During the cutting process, the length and error need to be strictly controlled. Moreover, some aluminum railings need to be processed by stamping or drilling. The purpose of these processes is to provide screw locations or space for glass installation. Therefore, the processing steps of these aluminum railings are important.

4. Weld aluminum tubes or railing frames:

Weld the cut and processed aluminum tube to assemble. There are various welding methods, such as TIG welding, argon arc welding, etc. The processor needs to control the welding strength and aesthetics to ensure its firmness and appearance quality.

Welding aluminum railings requires attention to wearing safety gloves, welding goggles, welding protective clothing and being in a dry environment. Welding process is a dangerous job! We must pay attention to safety and protect ourselves.

5. Surface Finishing of Aluminum Railing:

In order to improve the corrosion resistance and aesthetics of aluminum railings, surface treatment is usually required. Common surface treatments include powder coating and painting. These processes not only enhance the durability of the railings, but also give them rich colors and styles.

6. Finally, checking and packing railings

Quality inspection of aluminum railing:

Conduct quality inspection on the finished processed aluminum railing. The steps of quality inspection include:

- Appearance inspection

- Size measurement

- Material hardness test

- Comparison of design drawings

Packing of aluminum railing:

After confirming that the product quality is correct, cleaning and packaging treatment is carried out, ready for transportation to customers. Our common packaging methods are: wooden box, pearl cotton package, plastic package. For heavy weight welded aluminum railings: wooden pallets or welded iron frames for packaging.

High quality aluminum railing manufacturer here!

Manufacturing aluminum railings on your own is impossible to accomplish. This can only be achieved by finding a professional and excellent aluminum railing manufacturer

——Hugh Aluminum is a professional aluminum extrusion and aluminum railing manufacturer. Our team is professional and friendly and we have served 600+ customers from 40 countries in the past 14 years.

It is our aim to provide you with better aluminum products!

Don’t heasite to contact us!