Aluminum Channel Size: The Ultimate Guide for Selection, Standards, and Applications

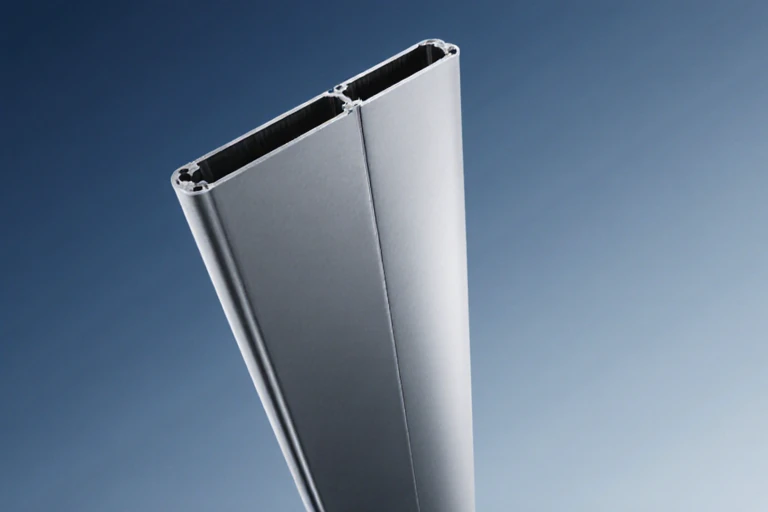

Aluminum channels are metal profiles shaped like a U or C. They are common in construction, manufacturing, and DIY projects. These channels offer strength while being lightweight. They resist corrosion and are easy to work with.

Choosing the right aluminum channel size is important. It affects how strong and safe your project will be. The correct size also controls costs and saves time. Picking the wrong size can cause problems like weak structures or extra expenses.

When you select the proper size, your project runs smoothly, whether you’re building frames, adding finishing touches, or making industrial equipment.

Understanding Aluminum Channel Size

Aluminum channel size refers to the main measurements that define the channel’s shape and strength. These measurements include:

- Width: The flat part connecting the two legs.

- Height: The length of the vertical sides.

- Thickness: The thickness of the metal forming the base and sides.

- Length: How long the channel piece is, either extruded or cut.

Channels come in different shapes, like U, C, or hat shapes. Most sizes follow standard measurements, but you can order custom sizes if needed.

You should measure both outside and inside dimensions. Sizes may vary slightly depending on the manufacturer and the type of aluminum. Think of it like buying clothing—two items of the same size can still fit differently.

More reading: How to cut aluminum extrusions cleanly?

Standard Aluminum Channel Sizes

Standard aluminum channel sizes vary between suppliers and regions, but typically fall within these ranges:

| Dimension | Typical Range |

|---|---|

| Width | 0.5″ (12.7mm) to 12″ (305mm) |

| Height | 0.5″ (12.7mm) to 4″ (101mm) |

| Thickness | 0.04″ (1mm) to 0.25″ (6.35mm) |

| Lengths | Standard extrusions up to 20′ or more |

Common sizes are often given in imperial or metric units, with some popular sizes such as 1/2″ x 1/2″ x 1/8″, 3/4″ x 3/4″ x 1/8″, and 2″ x 1″ x 1/4″. Light-duty to heavy-duty channels exist depending on thickness and size.

Most suppliers provide detailed aluminum channel size charts for quick referencing. Using these helps choose the correct profile based on typical applications and load-bearing requirements.

Custom Aluminum Channel Sizes

Standard aluminum channel sizes may not fit every project. You can order custom channels with:

- Different widths or heights

- Various wall thicknesses

- Shapes other than U or C profiles

- Specific lengths and finishes

Custom channels give you exact dimensions for your needs. They usually cost more but reduce waste and improve fit. Think of it like buying ready-made clothes versus a made-to-measure outfit—extra effort pays off in the end.

Material Grades and Their Relation to Size

Aluminum channels use different alloys, mostly from the 6xxx series, like 6061 and 6063.

- The 6061 alloy has good strength, resists corrosion, and is easy to machine.

- The 6063 alloy works well for architectural uses because it has a smooth finish.

Choosing the alloy affects the channel size. Stronger alloys let you use thinner walls or smaller channels without losing strength.

You should pick the wall thickness and size based on the alloy and the load you expect. It’s like picking the right tires for your car—using the wrong type can cause problems down the road.

Aluminum Channel Size vs Weight Calculation

Weight plays a key role in industries like aerospace, automotive, and construction. Reducing weight can lower costs and improve performance.

You can calculate weight using this formula:

The cross-sectional area depends on the channel’s width, thickness, and height. Aluminum’s density is about 2.7 g/cm³ (0.0975 lb/in³).

Manufacturers usually list weight per foot or meter. For example, a 6061-T6 channel sized 8″ x 2.29″ x 0.25″ weighs around 4.35 pounds per foot.

Weight affects shipping fees, handling ease, and final product design. Finding the right balance keeps things efficient without overburdening your project.

Applications and Use Cases Based on Size

Aluminum channels have many uses across different industries. Here are some common examples:

- Structural Framing: They create strong, lightweight frames for buildings, vehicles, and machines.

- Architectural Uses: Channels form window frames, door frames, curtain walls, and decorative trims.

- Industrial Equipment: They support conveyor belts, machine tables, safety guards, and ladders.

- DIY and Renovations: They help build shelves, partitions, and brackets.

- Transportation: Channels reinforce railings, truck beds, trailers, and airplane parts.

The size of the channel depends on the load it must carry, the space available, and the desired appearance. Choosing the right size ensures the structure fits and works as expected.

Purchasing Aluminum Channels: What Size Should You Choose?

To select the right aluminum channel size:

- Evaluate the load and stress your structure will endure.

- Consider weight limits and handling needs.

- Check dimensional compatibility with adjoining materials or slots.

- Determine if a standard size suffices or if a custom size is needed.

- Reference industry standards and consult supplier size charts.

- Purchase from reputable suppliers offering certified alloys and clear size specs.

Avoid common pitfalls like choosing too thin channels for heavy loads or overly large profiles that add unnecessary cost and weight.

Aluminum Channel Size Standards and Compliance

Aluminum channels follow clear standards to meet quality and size rules.

- ASTM B221 covers aluminum and alloy extrusions like bars, rods, and profiles.

- AMS QQ-A-200/8 sets rules for aerospace aluminum alloys.

- International and regional standards define size limits and testing methods.

These standards make channels dependable and safe for critical uses. No guesswork—just materials you can trust.

FAQs on Aluminum Channel Size

Use calipers and measuring tapes for width, height, thickness, and length. Measure internal and external dimensions if necessary.

Popular sizes include 1/2″ x 1/2″ x 1/8″, 3/4″ x 3/4″ x 1/8″, and larger structural channels up to 12″ wide.

Yes, aluminum cuts easily with saws, and most suppliers offer custom-cut lengths.

Yes, weight affects structural efficiency, cost, and handling.

Final Thoughts

Aluminum channel size is important for anyone using extruded aluminum. Understanding standard and custom sizes, material types, weight, and uses helps you choose well.

Always review size charts, manufacturer details, and industry standards before buying. The right size saves money, boosts safety, and keeps your project running smoothly.

Choosing the right aluminum channel size is like picking the right key—it unlocks success.