How strong is 2020 Aluminum Extrusion?

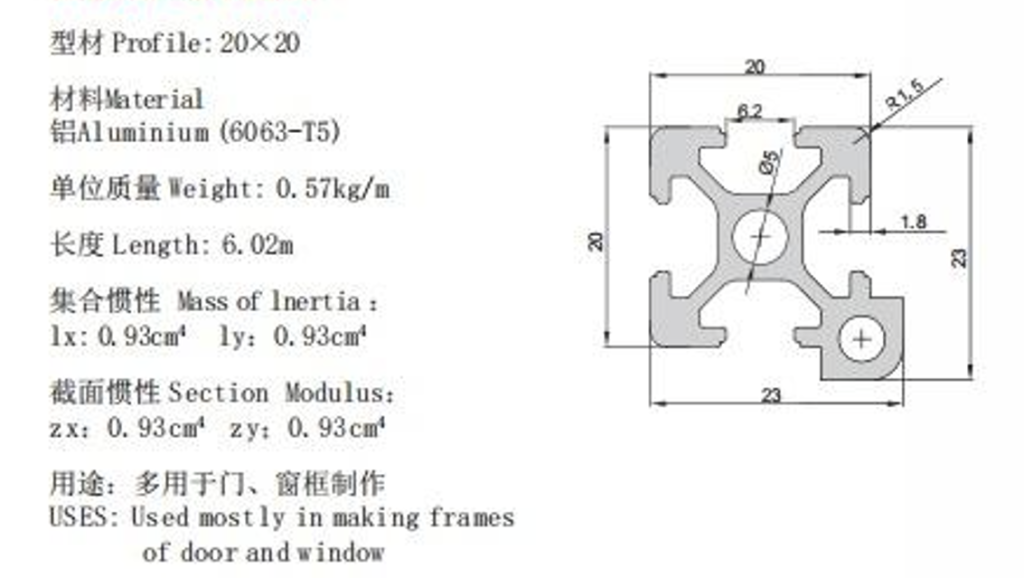

The 2020 aluminum extrusion is a 20 × 20 mm T-slot profile used in frames, enclosures, and light machinery. Makers like it because it is easy to assemble, adjust, and reuse.

It offers tensile strength between 230 MPa and 270 MPa. This range gives it enough capacity for building stable frames, equipment supports, and small load-bearing structures. It also resists bending well, which helps maintain shape under stress.

This guide explains its strength in simple terms. You will learn its load capacity, mechanical properties, and limits. We also compare it with other aluminum profiles so you can choose the right one for your project. By the end, you will know exactly if 2020 extrusion can handle your build — whether you are making a CNC frame or a heavy workbench.

What Does 2020 Mean?

In aluminum extrusion measurements, “2020” means the profile is 20 mm wide and 20 mm high. Each side includes a T-slot groove for connecting parts with brackets, bolts, or joining plates.

A standard 2020 profile has four open T-slots, one on each side. The same 20 mm series also includes 20 × 40, 20 × 60, 20 × 80, and 20 × 20RQ profiles.

The 2020 profile is strong enough for building frames, work platforms, and machine enclosures. Its strength depends on the alloy grade, the T-slot shape, and the wall thickness. We will examine these factors in the next section.

More reading: What is 2020 Aluminum Extrusion?

Alloy Type and Strength Criteria

The yield strength of 2020 aluminum extrusion is about 215 MPa. Stress beyond this point causes permanent deformation.

Common alloys for 2020 profiles are 6061‑T6 and 6063‑T5. Both provide higher strength and better stress resistance than standard architectural aluminum.

6061‑T6 delivers higher tensile strength and durability, making it suitable for heavy-duty builds. 6063‑T5 offers good strength with easier cutting, drilling, and surface finishing.

The choice of alloy affects how much load the profile can handle and how it performs under constant use. Selecting the right grade helps match the material to the project’s demands.

Calculation of Load-Bearing Capacity

The load-bearing capacity of aluminum profiles depends on their cross-sectional size, wall thickness, length, and tensile strength. You can calculate the load-bearing capacity (P) using this formula:

In this formula:

- D is the section diameter,

- t is the wall thickness,

- L is the length,

- σb is the tensile strength.

This equation helps you determine how much weight the aluminum profile can support based on its dimensions and material properties. Understanding this calculation is essential for ensuring that your projects are safe and effective.

Other Mechanical Properties

Aluminum profiles have important mechanical properties beyond strength and load-bearing capacity. These include elongation and hardness.

- Tensile Strength: The tensile strength of the 2020 aluminum extrusion ranges from 230 to 270 MPa.

- Bending Strength: The bending strength typically falls between 150 and 180 MPa.

These properties affect how aluminum performs in various applications. Knowing these characteristics helps you choose the right material for your project.

Connection Method

2020 aluminum extrusion connects with M5 or M4 T‑nuts and hex bolts. M5 T‑nuts are the standard choice for most builds. For higher strength, use 20‑series slider nuts with hex bolts.

To assemble, slide the T‑nut into the profile slot, align it with the bolt hole, and tighten it using a hex key. The process is quick, needs no special tools, and produces a secure joint.

This method works for frames, equipment supports, and other structures where strength and alignment are important.

2020 vs. 8020 Aluminum Extrusions

The main difference between 2020 and 8020 aluminum extrusions is their size and load-bearing capacity.

The 2020 profile measures 20 x 20 mm. It is compact and cost-effective, making it suitable for lightweight projects. This profile provides enough strength for moderate loads, ideal for applications like electronics and robotics.

The 8020 profile measures 80 x 80 mm. It offers larger dimensions and greater structural strength. This makes it better for heavy-duty applications that require higher load-bearing capacity.

Choosing between the two profiles depends on your project needs. Use 2020 for lightweight applications and select 8020 for projects that need more strength and stability. Each profile has its benefits, so assess your requirements to make the best choice.

Final Thoughts

The 2020 aluminum extrusion provides reliable strength for many structural projects. It meets common standards for framing and support, making it suitable for both light and medium-duty builds.

Compared to other aluminum profiles, 2020 offers a balance of strength, weight, and ease of assembly. It works well for machine enclosures, equipment supports, and custom frame construction.

If you need a profile that assembles quickly and holds its shape under load, the 2020 extrusion is a dependable choice.