How to Bend Aluminum Flat Bar?

How do you bend an aluminum flat bar after you buy it? Bending aluminum flat bars is a common task in metalworking. It allows you to create different shapes and structures for various projects.

There are two main methods for bending aluminum flat bars:

- Manual bending: This method uses your hands and tools. It’s great for small projects or when you need precise bends.

- Mechanical bending: This method uses machines to bend the metal. It’s best for larger pieces or when you need to make many bends quickly.

Bending aluminum can be enjoyable and rewarding. With the right technique, you can achieve clean and accurate bends. Let’s explore how to do it effectively.

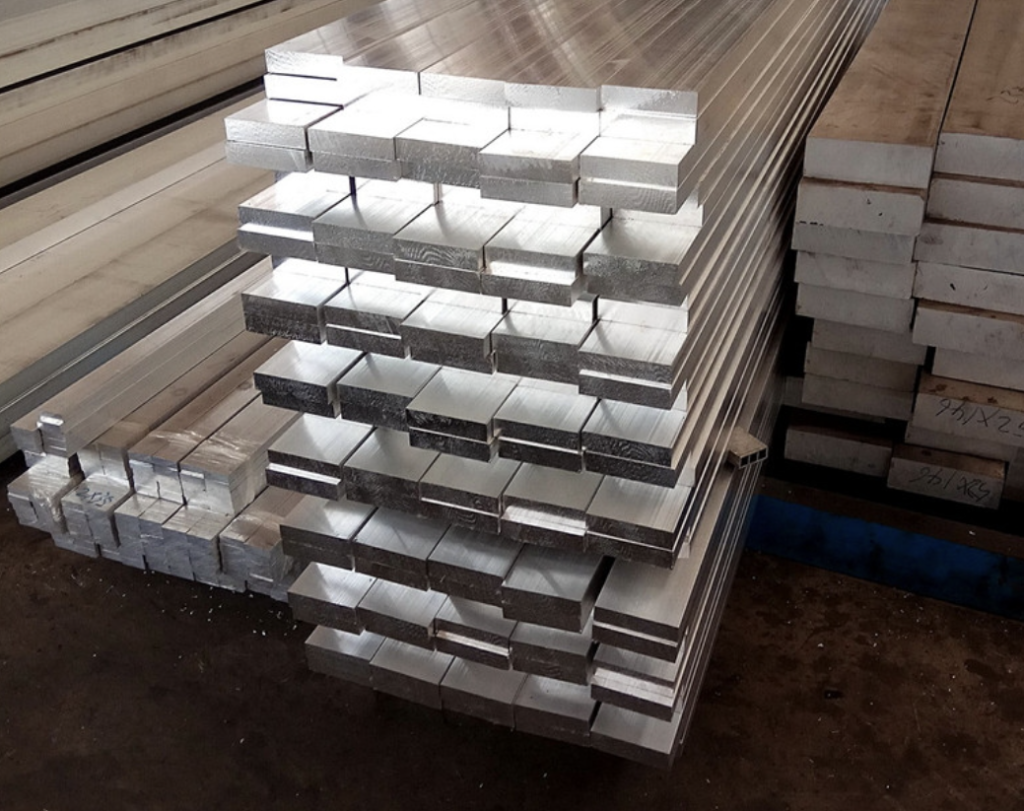

Related Products: Extruded Aluminum Bars Stock

What Do You Need to Know Before Bending?

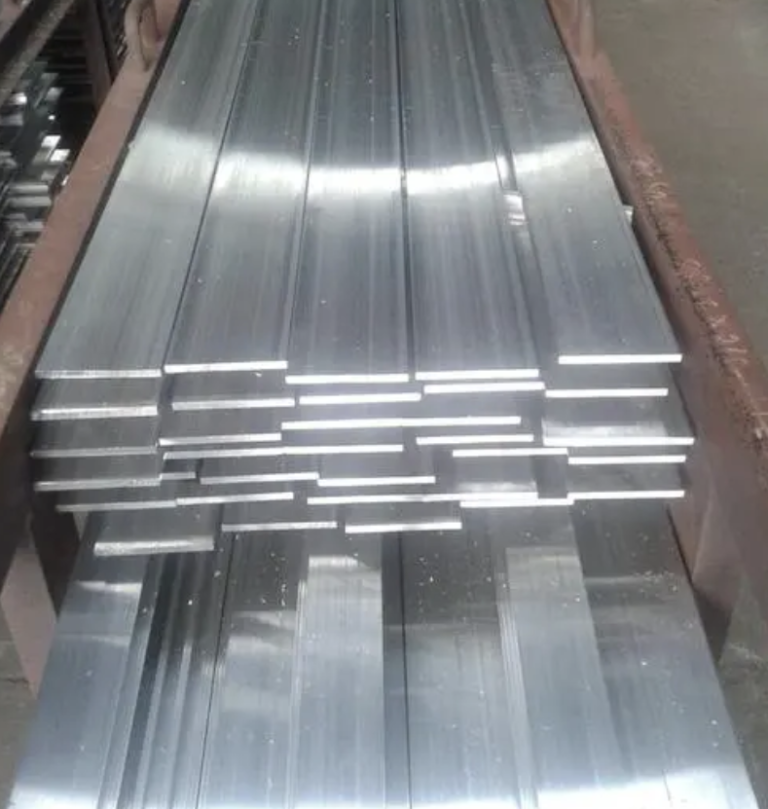

Before you start bending aluminum flat bars, knowing a few key facts about the material is important. Aluminum is ductile and malleable, which means it bends easily without cracking. This quality makes it popular in metalworking.

Aluminum is also lightweight, making it simple to handle. This is a big plus for various projects.

Grades 3003 and 5052 are the best choices for bending aluminum flat bars. These alloys are softer and more malleable than those in the 6xxx series. Their softness allows for easier bending, helping you achieve better results with less effort.

Keep these points in mind as you prepare to bend. Understanding your material will help you get the perfect bend every time.

What to Prepare for Bending Aluminum Flat Bar?

1. Clean the Surface

Begin by cleaning the aluminum flat bar. Remove any debris, rust, or dirt that could affect the bending process. Use a wire brush, sandpaper, or a solvent-based cleaner to achieve a clean surface.

2. Measure and Mark

Next, measure and mark the flat bar. This step is vital for setting the radius and angle of your bend. Use a tape measure or caliper for precise measurements. Mark the cut location with a water-based marker.

3. Cut the Flat Bar

Now, cut the flat bar to your desired length. You can use a hacksaw, circular saw, or band saw for this task. Make sure your cuts are clean and accurate. After cutting, you are ready to proceed with bending.

Manual Bending Method

What Tools and Materials Do You Need?

To bend an aluminum flat bar by hand, gather these tools:

- Aluminum bar bender

- Wood or iron plate

- Ruler

- Scissors

- Wrench

- Protractor

How to Bend Aluminum Flat Bar by Hand?

1. Use the Aluminum Bender

- Attach the aluminum flat bar to the bender.

- Gently bend the flat bar to your desired angle.

2. Use a Wooden or Iron Plate

- Clamp the flat bar at an angle with a wooden or iron plate.

- Carefully bend the board with the flat bar to achieve the desired angle.

3. Direct Bending by Hand

- For thin flat bars, bend them directly with your hands.

- Hold one end with one hand and bend the other end to your desired angle with your other hand.

What Should You Keep in Mind When Bending?

- Check for Defects: Inspect the surface for any cracks or defects before bending.

- Bend Within Limits: Ensure the bending angle is safe to avoid damage.

- Prioritize Safety: Use caution during bending. Avoid excessive force to prevent rebound.

By following these steps, you will bend the aluminum flat bar effectively and safely!

Use Mechanical Bending

How to Set Up the Bending Machine?

Before starting, set up the bending machine. Choose the correct dies and bending tools for your project. Select a die that matches your desired bend radius and insert it into the machine. Align the rollers and bending tool properly.

Steps for Bending

- Secure the Flat Bar: Place the aluminum flat bar in the bending machine.

- Adjust the Angle: Set the machine to your desired bending angle.

- Start the Machine: Press the button to bend the flat bar automatically.

For larger aluminum flat bars, use a heater to warm the material. Heating can make bending easier.

Important Cautions

- Check Length: Verify that the aluminum length is suitable for your project before bending.

- Monitor Temperature: Use the heater carefully. Avoid excessive heat to prevent deformation or damage.

- Finish Edges: After bending, remove any burrs or sharp edges. Use a deburring tool, sandpaper, or a file for a smooth finish. Clean the surface of the bent aluminum flat bar.

Understanding Bending Angle and Radius

- Bending Angle: The angle is critical for quality. A small angle may not meet your needs, while a large angle can lead to breakage or deformation.

- Bending Radius: The radius affects how much the aluminum deforms. A larger bending radius helps prevent cracking and deformation.

By following these steps and precautions, you will achieve accurate bends in aluminum flat bars using mechanical methods.

Wrapping Up

Choose the right method and tool for bending aluminum flat bars based on your needs. Prepare thoroughly before you start bending. Follow safety precautions during the process. These steps will help you achieve good results and avoid mistakes. Enjoy your bending project!