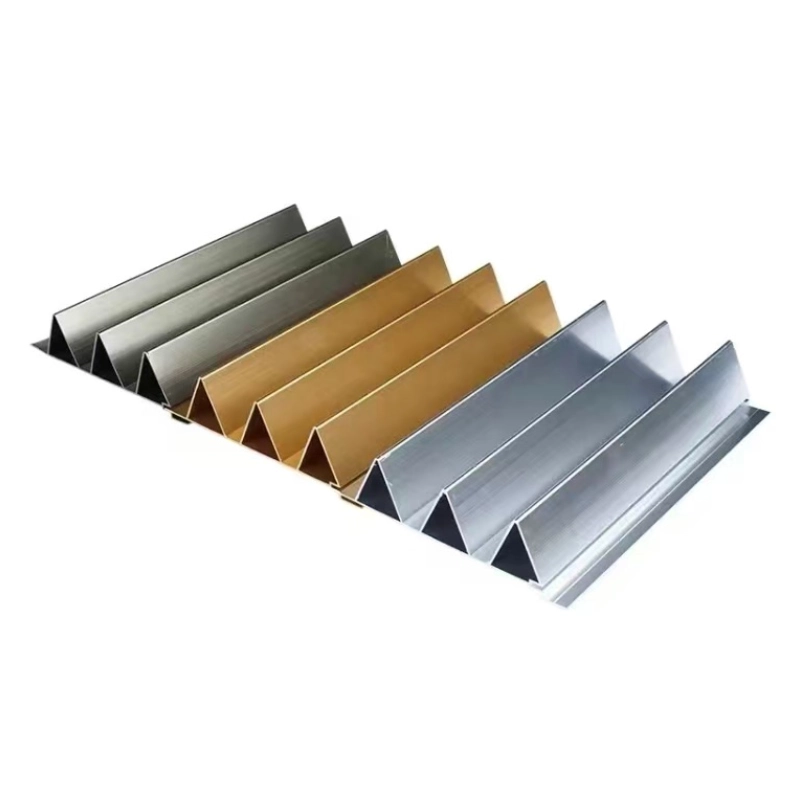

Triangular Aluminum Extrusions Profiles

| Item | Details |

|---|---|

| Type | Aluminum triangle extrusion |

| Material | 6xxx series (6063, 6061), 7xxx series for higher hardness |

| Size | Custom sizes available |

| Color and Finish | Mill finish, white, black, blue, red, gold, silver; custom colors available |

| Fabrication | Extruding, cutting, drilling, welding, CNC machining, punching, bending |

| Finishing Options | Anodizing, mill finish, electroplating, polishing, powder coating, wood grain, blasting, hard coating, PVDF |

| OEM & ODM | Contact the sales staff by email for options |

| Quality Control | ISO 9001 certified |

| Minimum Order | 300 KG |

| Payment | Contact sales staff by email for options |

Triangular aluminum extrusions are long pieces of aluminum with a triangle-shaped cross-section. Manufacturers create them by forcing aluminum through a die shaped like a triangle.

These extrusions are lighter than steel but still provide good strength. Their sharp angles make them easy to fit into corners or use as supports. People often choose them for building frames, shelves, or adding a modern look to projects.

Their shape also helps save material and weight. If you need a strong, neat, eye-catching profile, triangular aluminum extrusions are a smart choice.

Types and Variations

Triangular aluminum extrusions come in several types.

You can choose equilateral profiles, where all sides and angles are equal. These offer balanced strength and a uniform appearance.

Isosceles and scalene profiles have sides of different lengths. These work well for projects that need special shapes or extra support in certain areas.

Angle options include 45°, 60°, 90°, and 120°. Custom angles are available if your project requires a different fit.

Size choices range from 10mm to 100mm for side lengths. Thickness options go from 1mm to 10mm. Lengths can reach up to 6 meters, and custom lengths are possible.

Each type clearly offers an option for your project. Whether you need a perfect triangle or a shape with more variety, you can find the right fit.

Key Features and Benefits

- The triangle shape spreads weight evenly. This gives strong support for frames and structures.

- High-grade alloys like 6061 and 6063 resist rust. Anodized and powder-coated finishes add extra protection.

- Aluminum keeps the extrusion light. You can move and install it with little effort.

- Clean lines and sharp angles give a modern look. These profiles suit projects where appearance matters.

- You can cut, drill, and machine these extrusions with standard tools.

Triangular aluminum extrusions offer strength, low weight, and a clean finish. They make building easier, and the results look sharp.

Applications and Use Cases

Triangular aluminum extrusions work in many fields, from building and industry to transport and home projects. Their shape, strength, and light weight make them a practical choice.

Architectural and Construction

- Curtain wall systems use triangular extrusions for support or trim. A 60° equilateral profile fits modular facades.

- Sunshades and louvers use isosceles profiles with 45°–90° apex angles to block sunlight and allow airflow.

- Roofing and canopies use scalene profiles with a 100° apex to spread wind and snow loads.

Industrial and Mechanical

- Heat sinks use isosceles profiles with 80°–100° apex angles to increase surface area for cooling. 6063-T5 alloy helps with heat transfer.

- Conveyor guides and frames use 60° equilateral triangles for even load support.

- Equipment mounting uses thick scalene profiles (5mm or more) to support heavy machinery.

Transportation

- Aerospace and automotive industries use 6061-T6 extrusions for lightweight frames and battery covers. These meet AMS 2772 standards.

- Railway components use 5083-H111 profiles for bogie covers and seat tracks that resist corrosion.

Consumer and Decorative

- Furniture makers use slim profiles (1.5mm wall, 30°–60° angles) for table legs and brackets.

- Lighting fixtures use anodized triangular extrusions as LED housings. A 120° apex spreads light.

- Retail displays use powder-coated profiles in RAL colors for stands.

Energy and Infrastructure

- Solar panel mounts use 90° triangular rails for tilt adjustment. UV-resistant coatings increase lifespan.

- Transmission towers use 7075-T6 extrusions for lattice structures, especially where rust is a concern.

Production Process

Workers heat aluminum billets to the correct temperature. The heated billet passes through a die to form a triangular shape. The extrusion cools quickly and is straightened for accuracy. Workers cut the profile to the required length. Finishes like anodizing or powder coating are available on request.

Maximum Internal Angles

- Equilateral Triangle: Each angle is 60°. Use these for balanced structures such as space trusses.

- Isosceles Triangle: The apex angle ranges from 20° to 120°. Angles under 20° create sharp tips. Angles over 120° make the base unstable.

- Scalene Triangle: The largest angle is 150°. Custom dies are needed for angles above this. Common uses include heat sink fins (80°–100°) and architectural profiles (45°–90°).

Every step in this process produces accurate and reliable triangular extrusions. Each angle and cut serves a clear purpose.

Technical Specifications

- Material Grades: 6061-T6, 6063-T5, and other alloys by request.

- Dimensions: Side length: 10–100mm. Thickness: 1–10mm. Length: up to 6 meters.

- Tolerances: Precision extruded to ±0.2mm.

- Surface Finishes: Mill finish, anodized (clear, black, bronze), powder-coated (custom colors), brushed, or polished.

Quality Standards and Constraints

- Extrusion Limits:

- Angle tolerance: ±1° (meets GB/T 6892-2015 or EN 755).

- Minimum fillet radius: 0.5mm or more. This reduces stress and helps the die last longer.

- Structural Tips:

- For brackets and other load-bearing parts, keep the apex angle at 90° or less. Add reinforcing ribs for extra support.

- Decorative profiles can go up to 120°, but use thicker walls for strength.

These specifications help you pick the right extrusion for your project – no guesswork, just clear numbers and options. If only all decisions were this straightforward!

The Regular Size table:

| Parameter | Typical Range (mm) | Notes |

| Side Length (a=b=c) | 20–300 | Equilateral triangle (e.g., decorative trim, structural supports) |

| Base (c) | 30–500 | Isosceles triangle (a=b≠c, e.g., rails, heat sinks) |

| Height (h) | 10–400 | Calculated as h=a×sinθh=a×sinθ |

| Wall Thickness (t) | 1.2–8.0 | Structural use: ≥3mm (e.g., 6063-T6); decorative: 1.5–2.5mm |

Certifications and Quality Assurance

- Production uses ISO 9001:2015 certified processes.

- Each batch includes full traceability and material certificates.

- Products comply with RoHS and REACH standards.

You get clear records and reliable compliance – no extra steps or guesswork.

Frequently Asked Questions (FAQs)

Can I order custom sizes or finishes?

Yes! We offer full customization for dimensions, angles, and surface treatments.

What is the minimum order quantity (MOQ)?

Our MOQ is flexible-contact us with your requirements for a tailored quote.

Are these extrusions suitable for outdoor use?

Absolutely. With anodized or powder-coated finishes, they offer excellent weather and corrosion resistance.

Do you provide technical installation support?

Yes, our team is ready to assist with technical drawings, installation guides, and product selection.

Why Choose Our Triangular Aluminum Extrusions?

We deliver precise profiles for every order. You can select custom sizes, angles, and finishes. Our products meet strict quality standards. Architects, engineers, manufacturers, and DIY users rely on our extrusions.

You can order standard or custom designs. We ship on time and within budget.

Contact us for a quote or to discuss your project. We make the process simple and clear.

Reviews

There are no reviews yet.