What is 6061-T6 Aluminum Alloy?

6061-T6 aluminum is a widely used aluminum alloy. It belongs to the 6000 series. Magnesium and silicon are its main alloying elements. This combination gives the alloy medium strength, good corrosion resistance, and easy weldability.

The “T6” label shows the alloy has received a specific heat treatment. First, it is a solution heat-treated. Next, it is artificially aged. This process increases its strength and stability.

Manufacturers shape 6061-T6 aluminum using the extrusion process. They force the heated alloy through a die to create different profiles. You can find these profiles in construction, military equipment, bicycle frames, and many other products.

6061-T6 is strong, adaptable, and reliable. It is a top choice for projects that need a balance of strength, corrosion resistance, and workability.

Related products: Extruded aluminum profiles

Key Properties of 6061-T6 Aluminum Alloy

- High Strength and Hardness

6061-T6 stands out for its strength. After T6 heat treatment, it can handle heavy loads and pressure. Drop a hammer on it, and it won’t blink. - Good Corrosion Resistance

This alloy shrugs off rust and corrosion. It keeps its shine and strength, even in damp or harsh conditions. Salt air? No problem. - Easy Machining

Need to cut, drill, or mill it? 6061-T6 makes the job simple. It shapes up nicely for both simple and complex parts. - Excellent Welding Performance

Welding 6061-T6 is straightforward. It bonds well, making it a favorite for projects that need strong, clean joints. - Great Formability

Bend it, stretch it, or shape it—this alloy plays along. It can be formed into many shapes and sizes, fitting all sorts of creative or practical uses.

6061-T6 aluminum is strong, resists corrosion, and is easy to work with—like a reliable friend in your toolbox.

Common Applications of 6061-T6 Aluminum

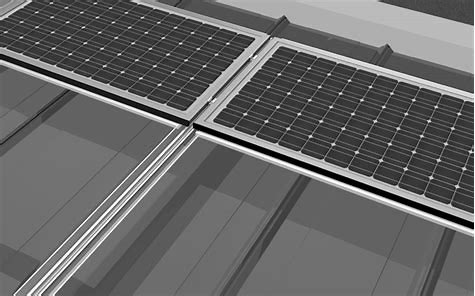

Construction Industry

Builders use 6061-T6 for frames, doors, windows, ceilings, and decorative panels. The alloy’s strength and corrosion resistance help buildings last longer. Its easy welding and forming saves time during construction.

Aerospace

Aircraft manufacturers use 6061-T6 for skins, fuselage frames, beams, rotor blades, and propellers. The material’s low weight and high strength improve aircraft performance. Its corrosion resistance protects parts at high altitudes.

Electronics and Electrical Appliances

Electronics companies use 6061-T6 aluminum for radiators, heat sinks, and electrical enclosures. The alloy conducts electricity and heat efficiently. This helps devices stay cool and work reliably.

6061-T6 aluminum supports many industries. Its strength, light weight, and corrosion resistance make it a practical choice for many products.

Final Thoughts

6061-T6 aluminum offers high strength, good corrosion resistance, and easy processing. You can weld, shape, and machine it with little effort.

These features make it useful in construction, aerospace, and electronics. Builders, engineers, and manufacturers rely on 6061-T6 aluminum for reliable performance.

This alloy handles tough jobs and adapts to many needs, making it a trusted choice across industries.