Aluminum Ceiling Panels Tiles

| Item | Aluminum ceiling system |

| Material | Aluminum Alloy |

| Color | Black, White, Gray,Wood like, Aluminum mill finish, Matt Black or Matt Gray, Sand coating or Customized(photo display will perfect) |

| Fabrication | Aluminum ceiling design, aluminum Extruding, Cutting, CNC machining, |

| Bottom Width | 10-300 mm |

| Height | 5-500 mm |

| Profile Thickness | 1.2-3.0 mm |

| Linear Length | 1000-6000 mm |

| Keel | Clip Keel, Carina Keel |

| Length of ceiling pendant | 300mm – 1000mm |

| Quality Control | ISO 9001 |

| Delivery time&Lead time | 21 days after sample confirmed & down payment |

An aluminum ceiling is a ceiling partition decoration material that facilitates air circulation, exhaust, and heat dissipation. Aluminum ceiling systems are extruded through molds. Its hardness and flatness are far better than other ceiling materials.

What is an Aluminum Baffle Ceiling System?

An aluminum baffle ceiling system is a kind of ceiling system processed by an aluminum alloy profile with a wind-baffle structure. It usually consists of several independent aluminum units, which can be flexibly arranged and combined to form a variety of beautiful and practical ceiling effects.

Aluminum Ceiling Panel Structure

Aluminum Panels

- Material: Extruded aluminum tubes or U-channels, oxidized, spray coated, powder coated, or other anti-corrosion treatments.

- Functionality: The main decorative surface for the ceiling, has a modern and sleek appearance. Not only decorative but also corrosion-resistant, fire-resistant, and damp-proof. The thickness of the aluminum profiles and surface treatments can be customized according to your needs.

Suspension or Carrier System

- Material: Aluminum profiles or galvanized steel, attached to the main structure of the ceiling to hold the aluminum panels.

- Functionality: This system supports and holds the ceiling panels, the design of the skeleton ensures the levelness of the ceiling system, easy to install, disassemble, and maintain.

Connecting Components and Accessories

- Include: Aluminum profile connectors, ceiling accessories and fixing bolts, all to ensure tight connection and easy assembly and disassembly.

- Functionality: These parts are used to connect the aluminum panels to the suspension system and adjust the height and level alignment effortlessly.

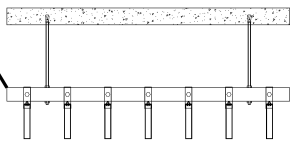

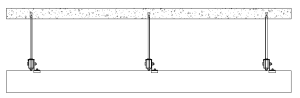

The Drawing Drafts

How to Install Aluminum Ceiling?

Foundation Setup: Study your design requirements and installation drawings first. These documents are crucial as they dictate the exact positioning of the aluminum bar ceiling.

Then anchor it to the overhead structure using expansion screws. Typically booms or support rods are spaced 1.1 meters apart. But if you’re using larger aluminum tube ceilings, space them proportionally for added support. Make sure the height of each boom is consistent across the installation for a level finish.

Kneeling to the Keel: Place the aluminum square tube (U-slot) ceiling keel onto the booms with precision. The keel is the base where the ceiling pieces will interlock.

To get the right alignment, fine-tune the height via the hole nut on the square keel. The keel should meet the design spacing requirements with precision.

Baffle Installation: The final step is to install the aluminum baffle strip ceiling onto the fixed keel. The keel should be custom-made to match the design spacing requirements. During installation, snap each aluminum ceiling panel into its designated slot on the keel. This step is critical as it determines the overall look and structural integrity of the ceiling.

Follow this and you’ll get a perfect aluminum ceiling installation. Remember to pay attention to details.

Why Choose the Aluminium Ceiling Panels?

Beautiful and Versatile Designs

Our Aluminium Ceiling System comes in a beautiful range of colors, textures, and styles to suit customer needs, fitting modern, minimalist, and industrial themes. This versatility adds to the overall look of any indoor space and gives it a touch of elegance.

Superior Durability

Made from aluminum alloy, our ceiling panels are weather-resistant and corrosion-protected. They look and function perfectly in humid and high-temperature environments and last more than 20 years. Compared to wood or plastic, aluminum alloy lasts longer.

Excellent Acoustic Performance

We add sound-absorbing materials to the back of our aluminum panels to improve the acoustic quality of the enclosed spaces. This is especially useful for rooms like conference rooms and concert halls where sound insulation is paramount.

High Strength and Lightweight

Our aluminum ceiling system is lightweight without sacrificing strength, easy to install and maintain, and reduces the load on the building structure. This gives more design flexibility compared to other metal ceiling systems. The high-strength aluminum alloy is also impact-resistant for durability and longevity.

Easy to Clean and Maintain

The smooth surface of our aluminum profiles makes cleaning and maintenance easy, and dirt-resistant and keeps the ceiling clean and looking good. This saves long-term maintenance costs.

Made with precision, our aluminum ceiling panels not only last long but also turn any architectural space into a work of art and functionality.

Aluminum Baffle Ceiling Applications

Aluminum baffle ceiling is widely used in various indoor places, including but not limited to:

- Commercial space: such as shopping centers, hotel lobbies, restaurants, and so on.

- Office space: aluminum baffle ceiling is used in offices, meeting rooms, and other places.

- Public space: such as airports, subway stations, exhibition halls and so on.

Reviews

There are no reviews yet.