Why Is CNC Machining Essential for High-Quality Aluminum Extrusions?

CNC machining uses computer-controlled machines to perform precise tasks like cutting, drilling, milling, bending, and laser cutting. It’s an efficient way to shape materials with high accuracy.

CNC stands for Computerized Numerical Control. This process relies on pre-programmed instructions to guide the tool and workpiece. The result is precise movements that create detailed and consistent designs.

What is CNC Machining?

CNC machining relies on three main components: a computerized control system, an actuation system, and the machine tool. The control system uses pre-programmed instructions to guide the machine’s movements. The machine tool provides the physical structure and tools required for machining.

This process can work with various metals, such as stainless steel, aluminum alloys, and copper. It supports tasks ranging from single-part production to large-scale manufacturing. Common applications include mold creation, component fabrication, and product assembly.

Tolerance and Precision in CNC Machining

Traditional machining methods, such as milling centers, can process aluminum profiles but often lack consistent accuracy. CNC machining overcomes these limitations by reducing errors and minimizing failed operations.

Aluminum extrusions are lightweight and strong, making them suitable for CNC machining. These machines achieve tight tolerances, often as precise as 0.01 mm. CNC milling is ideal for aluminum due to its ability to deliver high precision during the machining process.

CNC machining also controls surface roughness effectively. Aluminum parts can achieve smooth finishes, with roughness levels of Ra 0.8 μm or even Ra 0.4 μm in some cases.

Geometric accuracy is another advantage of CNC machining. It maintains parallelism and perpendicularity within 0.02 mm, meeting strict design requirements for aluminum extrusions with reliability and precision.

4-Axis vs. 5-Axis CNC Machining: Achieving Precision in Aluminum Extrusions

4-axis and 5-axis CNC machines are ideal for aluminum extrusions requiring high precision. These machines include an additional rotary axis (A, B, or C), which allows the cutting tool to approach the workpiece from various angles. This flexibility improves accuracy and enables precise machining of complex shapes.

Imagine it like rotating a puzzle piece to fit perfectly—these machines adjust the workpiece’s angle to achieve the best cutting position. They are especially useful for intricate designs and tight tolerances.

At Hugh Aluminum, we specialize in precision machining. Our facility is equipped with three 4-axis CNC machines and aluminum extrusion lines ranging from 600 to 1,800 tons. If you need reliable extruded aluminum parts, contact us today.

CNC Machining Extruded Aluminum Parts

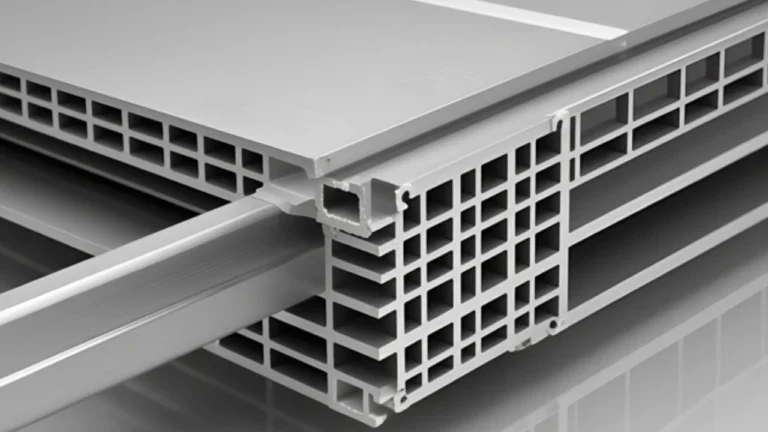

CNC machining processes aluminum extrusions into precise parts used in various industries. It includes techniques like turning, milling, and grinding to create components with high accuracy. These parts are widely used due to their durability and versatility.

Here are examples of CNC-machined aluminum extrusion parts:

- Electronic enclosures: Protect electronic devices from physical damage.

- Aluminum heat sinks: Dissipate heat to maintain device performance.

- EMI housings: Block electromagnetic interference for sensitive equipment.

- Automotive parts: Improve vehicle efficiency with lightweight designs.

- Medical equipment: Provide reliable components for healthcare tools.

- Lighting fixtures: Combine durability with modern designs.

- Aluminum handles: Enhance strength and usability in various products.

CNC machining ensures that aluminum extrusions are shaped accurately for these applications. These parts play a vital role in industries ranging from electronics to healthcare, making them essential for everyday functionality.

Why is CNC Machining Critical for Aluminum Extrusion?

High precision machining

CNC machines process aluminum profiles with exceptional accuracy. Through programmed control, they ensure the dimensions, shapes, and surface finishes meet exact design specifications. This improves product quality and consistency.

Processing complex shapes

Aluminum extrusion often requires intricate designs, such as curves, hollows, and custom profiles. CNC machining handles these complex shapes efficiently, making it possible to meet diverse industry requirements.

Efficient production

CNC machining automates production, enabling continuous and stable operation. It increases output speed while maintaining quality. Additionally, it supports small-batch production for varied market needs.

Reduced labor intensity

Traditional methods demand significant physical effort. CNC machining automates tasks, reducing the workload on workers and streamlining operations.

Final Thoughts

CNC machining is essential for modern manufacturing. It offers precision, efficiency, and automation for aluminum extrusion. These advantages improve product quality, reduce labor demands, and support sustainable practices by minimizing waste.

This technology drives progress in aluminum extrusion by meeting industry needs with accuracy and speed. Its ability to combine high performance with environmental responsibility makes it a key factor in advancing manufacturing processes.