What Is a T-Slot Aluminum Profile? Properties, Sizes, Applications and Benefits

A strong frame is important for any project that needs stability. T-slot aluminum profiles offer strength, flexibility, and a cost-effective solution for building frames. You can use them for stages, workbenches, equipment stands, and more.

Traditional materials need welding, drilling, or bolting. Making changes later is hard and time-consuming. T-slot aluminum profiles make assembly and adjustments simple. You can connect or disconnect pieces with basic tools, which saves time and effort.

Many people have not used T-slot aluminum before. This article explains what T-slot aluminum profiles are, how manufacturers produce them, and where you can use them. If you’re looking for a building material that is easy to work with and reliable, T-slot aluminum profiles are a worthwhile consideration.

Table of contents:

- What is T-slot aluminum?

- Properties and Benefits of T-slot aluminum

- Application of T-slot frame

- Size of the T-slot aluminum

- How to Identify Different T-slot Aluminum Extrusions?

What is T-slot Aluminum?

T-slot aluminum is an extruded profile made from aluminum alloy. Each piece has T-shaped slots along its sides. These slots let you slide in T-nuts and connectors. You can attach parts wherever you need them.

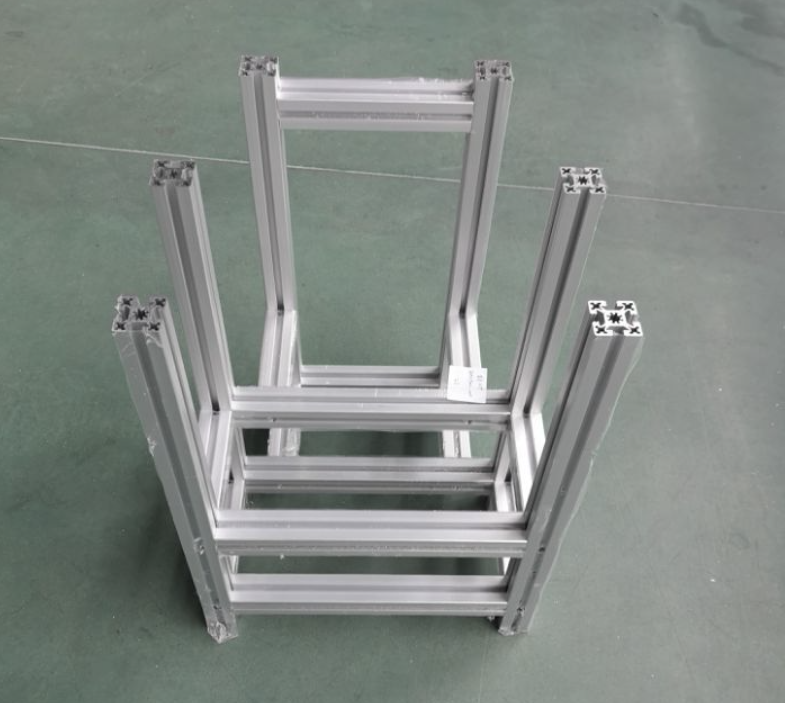

People use T-slot aluminum to build frames. You see it in workbenches, machine guards, display stands, and event stages. The system works like building blocks for adults. You connect and adjust pieces as needed.

Most profiles are square or rectangular. The common alloys are 6063-T5 and 6105-T5. Manufacturers create these profiles by pushing heated aluminum through a shaped die.

T-slot aluminum gives you a simple way to build strong frames. You do not need welding or drilling. You can change or move parts easily. This makes T-slot aluminum a popular choice for many projects.

Key Properties and Benefits

High Strength – T-slot aluminum uses strong alloys like 6063-T5 and 6061-T6. These alloys support heavy loads. The profiles keep their shape under pressure.

Lightweight – Aluminum weighs less than steel. You can lift and move the profiles easily. This makes installation faster and simpler.

Corrosion Resistance – A thin oxide layer forms on the surface. This layer protects the aluminum from rust and scratches. T-slot aluminum works well in humid or salty environments.

Flexible Connections – The T-slots let you slide in bolts and nuts at any point. You can attach parts where you need them. You can also change or move parts without special tools.

Modular Assembly – You can build frames in different shapes and sizes. You can add, remove, or adjust parts as your project changes. The system works like building blocks.

Eco-Friendly and Recyclable – Aluminum is recyclable. T-slot frames do not release harmful substances. You can recycle the material after use.

T-slot aluminum gives you strength, flexibility, and easy assembly. It is a smart choice for many building projects.

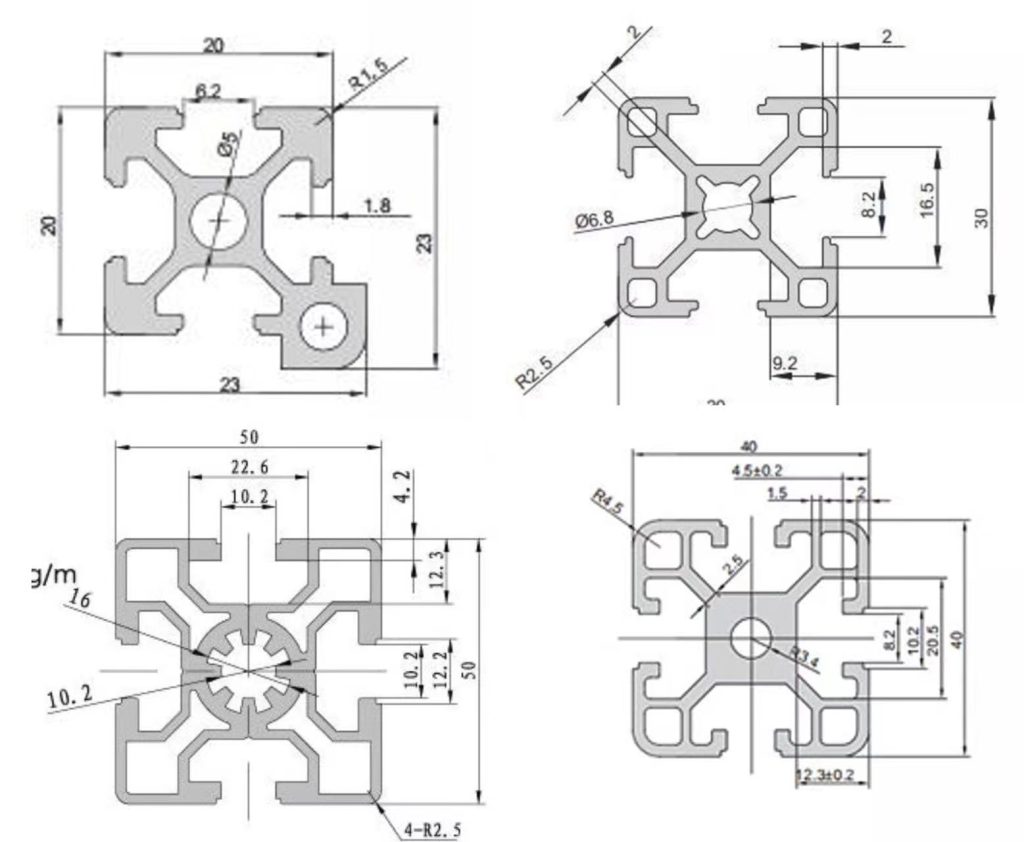

Common Sizes of T-slot

T-slot aluminum profiles come in standard sizes. These sizes fit most building needs.

- Width: 20 mm to 60 mm

- T-slot size: 2 inches to 8 inches

- Length: 30 inches to 9 feet 10 inches

- Wall thickness: At least 0.65 inches (varies by strength needed)

Manufacturers also offer custom sizes for special projects. Most users choose from the standard options.

The drawings below show T-slot profiles from 20 mm to 50 mm wide. These sizes work for many frames and structures.

If you need more information or a special size, contact an aluminum profile supplier. They can help you find the right fit for your project.

How to Identify Different T-slot Aluminum Extrusions?

T-slot aluminum profiles use simple codes to show their size. For example, a “2020” profile measures 20×20 mm. A “4040” profile measures 40×40 mm. These numbers help you quickly understand the size.

Profiles come in size groups:

- 10 series: 10×10 mm

- 20 series: 20×20 mm

- 30 series: 30×30 mm

Larger numbers mean bigger profiles.

Different regions have different standards. European, American, and Chinese profiles follow their own sizing rules. Check the standard before buying to avoid fitting problems.

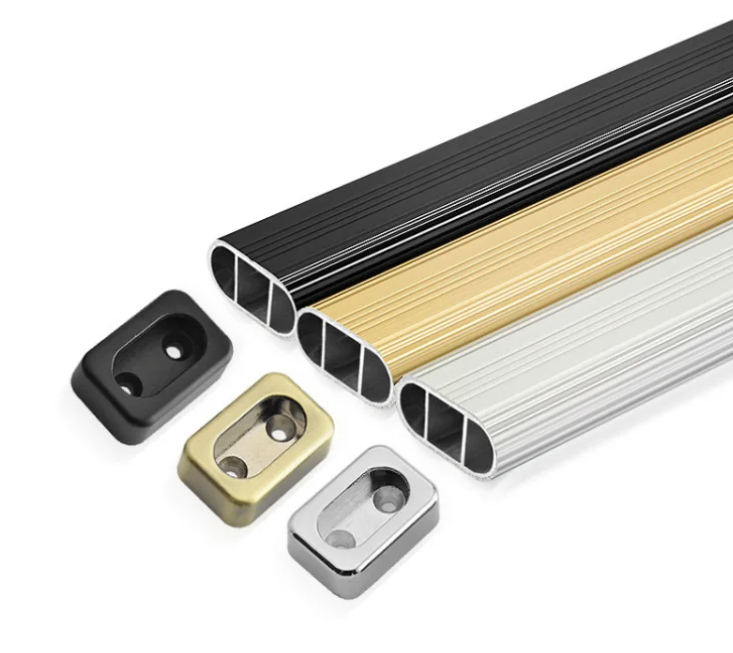

T-slot systems include three main parts:

- Profiles: Various shapes and sizes for different uses.

- Fasteners: T-nuts, screws, and connectors to hold pieces together.

- Accessories: Panels, wheels, and handles for added features.

Picking the right profile size and standard helps your project fit perfectly. Think of it like choosing the right puzzle pieces—they have to match to build a solid frame.

Applications of T-slot Aluminum Extrusion

Industrial Equipment Frames: Factories use T-slot aluminum for machine bases, conveyor supports, and safety guards. The profiles are strong and light. Workers can move and adjust them quickly.

Store Displays and Exhibition Stands: Retailers use T-slot frames for shelves and trade show booths. The frames look modern. You can take them apart and rebuild them to fit new displays.

Staging and Event Platforms: Event planners use T-slot aluminum for concert stages and party platforms. The frames set up fast, even on uneven ground. After the event, you can take them apart and use them again.

T-slot aluminum works for many projects. It is easy to build, move, and change as needed.

Final Thoughts

T-slot aluminum profiles help you build strong, light, and flexible frames. You can use them for machines, displays, or stages. They make assembly and changes simple.

Consider T-slot aluminum for your next project. It is reliable and cost-effective.

For more choices and prices, visit Hugh Aluminum’s T-slot Aluminum Extrusions page. Find the right fit for your needs.