Aluminum Flat Bar 101: Benefits, Types, and Practical Applications

Aluminum flat bars are versatile materials used in many industries. They are known for their strength, lightweight nature, and resistance to corrosion. These qualities make them essential in construction, manufacturing, automotive applications, and more.

This guide will cover the key benefits of aluminum flat bars, the different types available, and their practical uses in various projects. By the end of this article, you will understand how to choose and apply flat bar extrusions effectively.

Related products: Extruded Aluminum Bar Stock

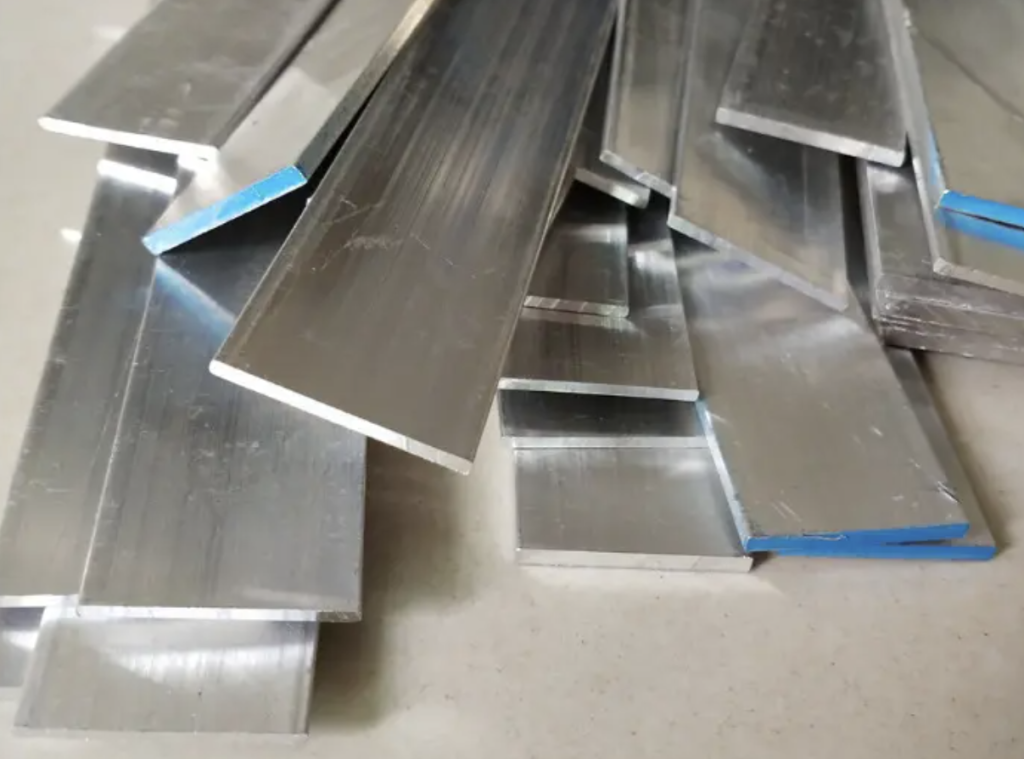

What is the Aluminum Flat Bar?

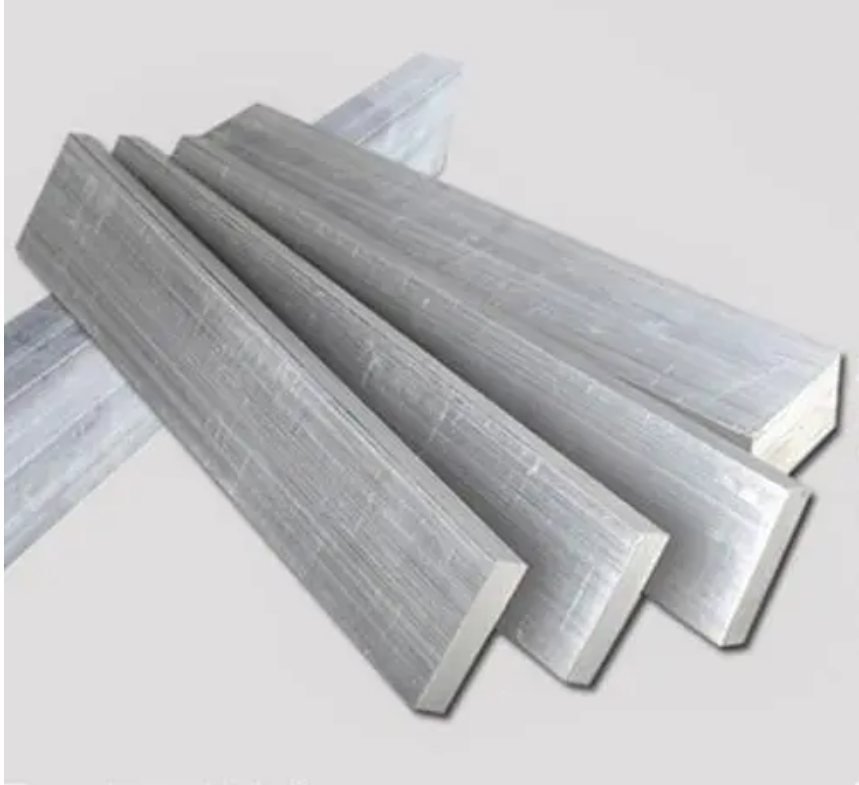

An aluminum flat bar is a flexible material used in various applications. It comes in different shapes and sizes, including thin and thick options. The most common shapes are rectangular and round. Round bars often provide support, while rectangular bars serve as surfaces or packaging.

Specifications of the Aluminum Flat Bar

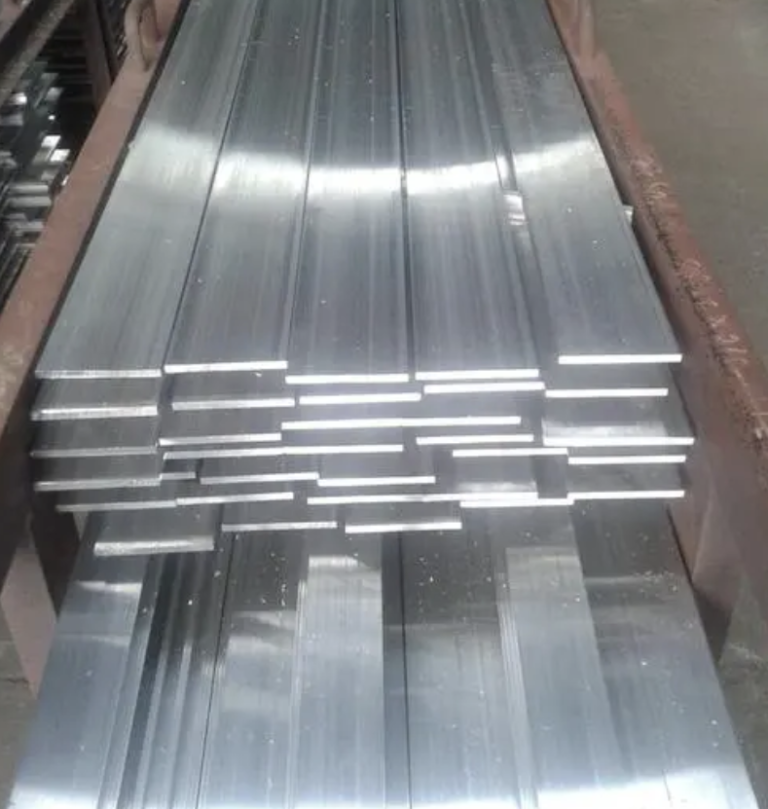

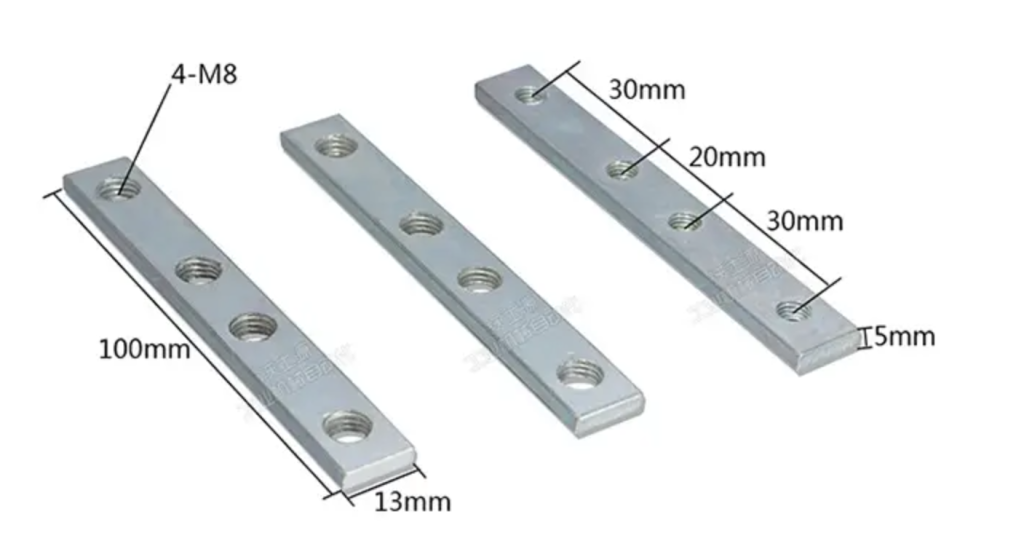

Key specifications for aluminum flat profiles include length, width, and thickness. Many manufacturers offer custom lengths, but standard lengths are also available. Common options are 1 meter, 2 meters, and 3 meters.

Width and thickness are important for determining how a flat bar can be used. Selecting the right dimensions is crucial for meeting specific project needs. The better the fit, the more effective the bar will be.

Aluminum flat stock comes in various sizes:

- Thickness: Ranges from 1/8 inch (3.2 mm) to 2 inches (50.8 mm) or more.

- Width: Common widths range from 1 inch (25.4 mm) to 8 inches (203.2 mm) or larger.

- Length: Standard lengths are usually 6 feet (1.83 meters), 12 feet (3.66 meters), or 24 feet (7.32 meters). Custom lengths can be cut as needed.

Extruded flat bars are essential materials for many industries. Understanding their specifications helps you make informed decisions for construction, manufacturing, or DIY projects. Choosing the right flat bar can lead to better results in your work.

| Thickness | Width | Length |

|---|---|---|

| 1/8 inch (3.2 mm) | 1 inch (25.4 mm) | 6 feet (1.83 meters) |

| 1/4 inch (6.4 mm) | 2 inches (50.8 mm) | 12 feet (3.66 meters) |

| 1/2 inch (12.7 mm) | 4 inches (101.6 mm) | 24 feet (7.32 meters) |

The Material Classification of Aluminum Flat Bars

Aluminum flat bars are classified based on their alloy composition and temper. These factors affect their strength, mechanical properties, and corrosion resistance. Here’s a simple breakdown of the classifications:

Alloy Series Classification

Aluminum alloys are grouped into series, indicated by a four-digit code. The first digit shows the main alloying element.

1000 Series (Pure Aluminum)

- Composition: Contains 99% or more pure aluminum.

- Properties: Offers excellent corrosion resistance and high thermal and electrical conductivity, but has low strength.

- Common Alloys: 1100, 1050.

- Applications: Used in chemical processing equipment, heat exchangers, and electrical components.

2000 Series (Copper Alloy)

- Composition: Copper is the primary alloying element.

- Properties: Provides high strength and good machinability, but has lower corrosion resistance.

- Common Alloys: 2024.

- Applications: Common in aerospace structures and high-stress components.

3000 Series (Manganese Alloy)

- Composition: Manganese serves as the main alloying element.

- Properties: Offers good corrosion resistance, moderate strength, and excellent formability.

- Common Alloys: 3003, 3105.

- Applications: Used in building products and cooking utensils.

4000 Series (Silicon Alloy)

- Composition: Silicon is the primary alloying element.

- Properties: Features a low melting point with good wear resistance.

- Common Alloys: 4032, 4043.

- Applications: Ideal for automotive engine components and welding filler materials.

5000 Series (Magnesium Alloy)

- Composition: Magnesium is the main alloying element.

- Properties: Provides excellent corrosion resistance with moderate to high strength.

- Common Alloys: 5052, 5083, 5754.

- Applications: Commonly used in marine applications and structural components.

6000 Series (Magnesium and Silicon Alloy)

- Composition: Magnesium and silicon are the primary alloying elements.

- Properties: Offers good strength with excellent corrosion resistance and weldability.

- Common Alloys: 6061, 6063.

- Applications: Used in structural components and architectural applications.

7000 Series (Zinc Alloy)

- Composition: Zinc is the main alloying element.

- Properties: Provides very high strength but lower corrosion resistance.

- Common Alloys: 7075.

- Applications: Often found in aircraft parts and high-performance applications.

Knowing the classification of extruded flat bars helps you select the right material for your needs. Each series has specific properties that fit various industrial applications. This knowledge can guide you in making informed choices for your projects.

Comparison Table of Alloy Series

| Alloy Series | Primary Alloying Element | Strength | Corrosion Resistance | Workability | Applications |

|---|---|---|---|---|---|

| 1000 Series | Pure Aluminum (99%+) | Low | Excellent | Excellent | Electrical, chemical processing |

| 2000 Series | Copper | High | Low | Fair | Aerospace, military |

| 3000 Series | Manganese | Moderate | Good | Good | Building products, heat exchangers |

| 4000 Series | Silicon | Moderate | Fair | Fair | Automotive components, welding |

| 5000 Series | Magnesium | High | Excellent | Good | Marine applications, structural |

| 6000 Series | Magnesium and Silicon | Moderate | Good | Excellent | Structural, architectural |

| 7000 Series | Zinc | Very High | Fair | Poor | Aerospace, high-performance |

Aluminum Magnesium Alloy

Aluminum magnesium alloys offer excellent heat resistance and corrosion resistance. They are perfect for high-temperature environments. If your project involves extreme conditions, consider using a flat bar profile with magnesium.

Choosing the Right Aluminum Flat Bar

Selecting the right flat profile depends on your specific needs. Each type has distinct advantages, so match the material to your requirements for optimal performance and durability.

Also, pay attention to dimensions. The right size is essential for achieving the desired results in your project. Assess your needs carefully and choose accordingly.

The Benefits of Aluminum Flat Bars

The flat bar extrusions offer many advantages that make them suitable for various applications. Here are the main benefits:

1. Eco-Friendly and Recyclable

Extruded flat bars are environmentally friendly. Unlike traditional materials like iron or copper, aluminum is highly recyclable. Its production generates less pollution, making it a safer choice for construction.

2. Corrosion Resistance

The flat profile bars resist corrosion effectively. They perform well in harsh environments, such as coastal areas and high-humidity locations. This durability means they last longer without deforming or sustaining damage.

3. Strength and Stability

Aluminum flat bars provide excellent strength and stability. This strength keeps constructions firm and safe. Stability is crucial in construction, where safety is a top priority.

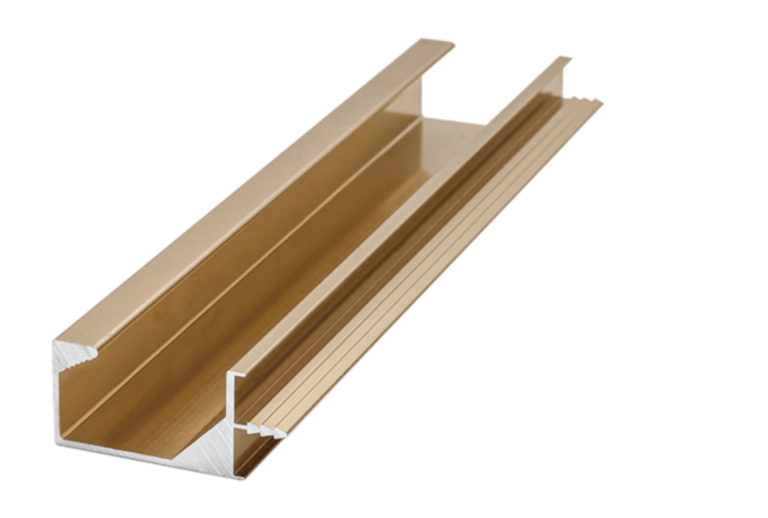

4. Aesthetic Appeal

Extruded flat bars are visually appealing. They can be treated to achieve various colors and textures, meeting modern design demands. This flexibility allows architects to combine functionality with style.

5. Thermal and Electrical Conductivity

The flat profile conducts heat and electricity well. This property makes them suitable for electrical applications, such as bus bars and heat sinks in electronics. Their ability to dissipate heat efficiently is valuable in heat exchangers.

6. Lightweight

Aluminum is about one-third the weight of steel, making it easy to handle and transport. This lightweight nature is essential in industries like automotive and aerospace, where reducing weight improves performance.

7. Cost-Effectiveness

Aluminum flat profile are affordable compared to other metals like stainless steel or copper. They offer great durability at a lower cost. Their corrosion resistance also means minimal maintenance, reducing long-term expenses for applications such as railings and outdoor furniture.

Aluminum flat stock provides numerous benefits that make it a preferred choice in construction and manufacturing. Their eco-friendliness, strength, aesthetic appeal, and cost-effectiveness contribute to their widespread use across various industries.

The Uses of Aluminum Flat Bars

Aluminum flat bars are versatile materials used in many industries. Here’s a clear overview of their applications:

1. Construction and Architecture

- Structural Support: The flat bar extrusions are strong components in frameworks, beams, and brackets.

- Window and Door Frames: They are commonly used to make window and door frames, as well as sliding tracks.

- Decorative Trim and Molding: These bars enhance interior design with trim, edging, and decorative elements.

- Fencing and Railings: They are often used for handrails, fencing, and gates in both residential and commercial settings.

2. Automotive and Transportation

- Vehicle Parts: Aluminum flat profile help construct automotive parts like frames, panels, and mounting brackets where weight reduction is essential.

- Trailers and Truck Bodies: They are widely used in trailer frames and truck beds for their strength and lightweight properties.

- Aircraft and Marine Components: Aluminum’s corrosion resistance makes it suitable for marine fittings and aerospace applications.

3. Electrical and Industrial Applications

- Bus Bars: Aluminum flat bars serve as bus bars in electrical panels for power distribution due to their excellent conductivity.

- Heat Sinks: Their thermal conductivity makes them ideal for cooling systems in electronics, including heat sinks.

- Machinery and Equipment: These bars are used to manufacture various machine parts, brackets, supports, and housings.

4. Fabrication and Manufacturing

- Custom Metalwork: Fabricators use the flat bars for projects like metal sculptures, furniture, and fixtures.

- Frames and Supports: They are essential in building frames for industrial equipment, storage racks, and shelving units.

- Tooling and Jigs: Aluminum flat bars create tooling fixtures, jigs, and workbench supports due to their ease of shaping.

5. Signage and Advertising

- Sign Frames: Aluminum flat bars provide strong yet lightweight frames for signs, billboards, and display structures.

- Mounting Systems: They are used in advertising installations, banner stands, and display supports.

6. Marine Applications

- Boat Building: These bars are commonly found in boat hulls, decks, and handrails because of their corrosion resistance.

- Dock and Pier Construction: Aluminum flat bars support dock edging, cleats, and other structures exposed to water.

7. DIY Projects and Home Improvement

- Shelving and Furniture: They are popular for building custom shelves, tables, and other furniture pieces during home improvement projects.

- Decorative Elements: Aluminum flat bars can be used for custom edging or brackets in various projects.

8. Renewable Energy

- Solar Panel Mounting Systems: Aluminum flat bars help construct mounting brackets and support frames for solar panels.

- Wind Turbines: They serve as structural supports in wind turbine components due to aluminum’s strength.

Aluminum flat bars have a wide range of applications across many sectors. Their strength, lightweight nature, corrosion resistance, and versatility make them valuable in construction, manufacturing, transportation, renewable energy, and more.

How to Pick the Right Aluminum Flat Bar?

Choosing the right aluminum flat bar involves several key factors. Here’s a clear guide to help you make the best choice:

Determine Application Requirements

Understand what you need for your project:

- Structural Support: For load-bearing applications, select an alloy with high strength and durability.

- Aesthetic Use: If the bar is visible, choose one with a smooth finish or anodized surface.

- Conductivity Needs: For electrical or thermal applications, pick an alloy that enhances conductivity, such as those used in bus bars or heat sinks.

Consider Temper (Hardness and Strength)

Aluminum flat bars come in different tempers, which indicate their hardness and strength:

- T6 Temper: Provides maximum strength, suitable for structural uses.

- T5 Temper: Balances strength and workability, ideal for moderate bending.

- O Temper: Fully annealed for maximum flexibility, making it easy to shape.

Evaluate Dimensions and Tolerances

Check that the dimensions of the flat bar match your project specifications:

- Standard Sizes: Aluminum flat bars are available in various standard sizes, but custom lengths can be ordered.

- Tolerances: Determine if precise tolerances are necessary for your application.

Assess Cost and Budget

Consider how alloy choice, temper, and finish affect cost:

- Lower-Cost Options: Alloys like 6061 are affordable and versatile for many uses.

- Premium Options: Alloys such as 7075 are pricier but offer higher strength for specialized applications.

Selecting the right aluminum flat bar requires careful evaluation of your project’s needs. By considering application requirements, temper, dimensions, and budget, you can make an informed decision. This approach will help you achieve optimal performance and durability in your projects.

How to Find the Right Manufacturer for Aluminum Flat Bars?

Finding a reliable manufacturer for aluminum flat bars is essential for ensuring quality and meeting your project needs. Here are some steps to help you identify the right manufacturer:

Research Manufacturers

Start by exploring various manufacturers in the aluminum extrusion industry. Look for companies with a solid reputation and extensive experience. Well-known brands often provide better quality products and customer service.

Evaluate Product Range

Check the range of products offered by potential manufacturers. A good manufacturer should provide a variety of aluminum profiles, including standard and custom options. For example, Hugh Aluminum offers a wide selection of regular and special profiles, catering to diverse needs.

Consider Quality Assurance

Look for manufacturers that emphasize quality control. Companies like Dhanlaxmi Steel ensure their products meet industry standards through rigorous testing and high-quality materials. This commitment to quality can lead to better performance in your applications.

Check for Customization Options

Many projects require specific designs or dimensions. Choose a manufacturer that offers customization services, such as OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer). This flexibility can help you get the exact product you need.

Read Reviews and Testimonials

Look for customer reviews and testimonials about the manufacturers you are considering. Positive feedback from other clients can indicate reliability and satisfaction with their products and services.

Assess After-Sales Support

Good after-sales support is crucial for addressing any issues that may arise after your purchase. A manufacturer with strong customer service will help you resolve problems quickly and efficiently.

Compare Pricing

Finally, compare prices among different manufacturers. While cost is important, it should not be the only factor in your decision. Ensure that you balance price with quality and service.

Finding the right manufacturer for aluminum bars involves researching options, evaluating product ranges, checking quality assurance practices, considering customization, reading reviews, assessing after-sales support, and comparing prices.

By following these steps, you can select a manufacturer that meets your needs and delivers high-quality products for your projects.

Q&A

How to Get a Lower Price on the Flat Bars?

Prices for aluminum extruded flat bars vary widely. Many people look for the cheapest options, but it’s crucial to prioritize quality. While lower-priced aluminum profiles may seem appealing, reputable brands often provide better value.

For example, Hugh Aluminum is a trusted manufacturer. Their prices may not be the lowest, but they deliver high-quality products. With them, you can avoid worries about quality issues.

How to Choose a Good Flat Bar?

Start by ensuring the flat profile bar meets industry standards. Standard products balance quality and cost. If a manufacturer does not follow these standards, it’s best to avoid their products. Even if they offer lower prices, poor quality can lead to significant problems later.

Consult manufacturers, dealers, or designers for recommendations. They often suggest reputable brands known for their quality. Research these brands and consider their products for your projects.

In summary, focus on quality over price when selecting extruded flat bars. A reliable manufacturer will provide products that meet your needs without compromising safety or performance.